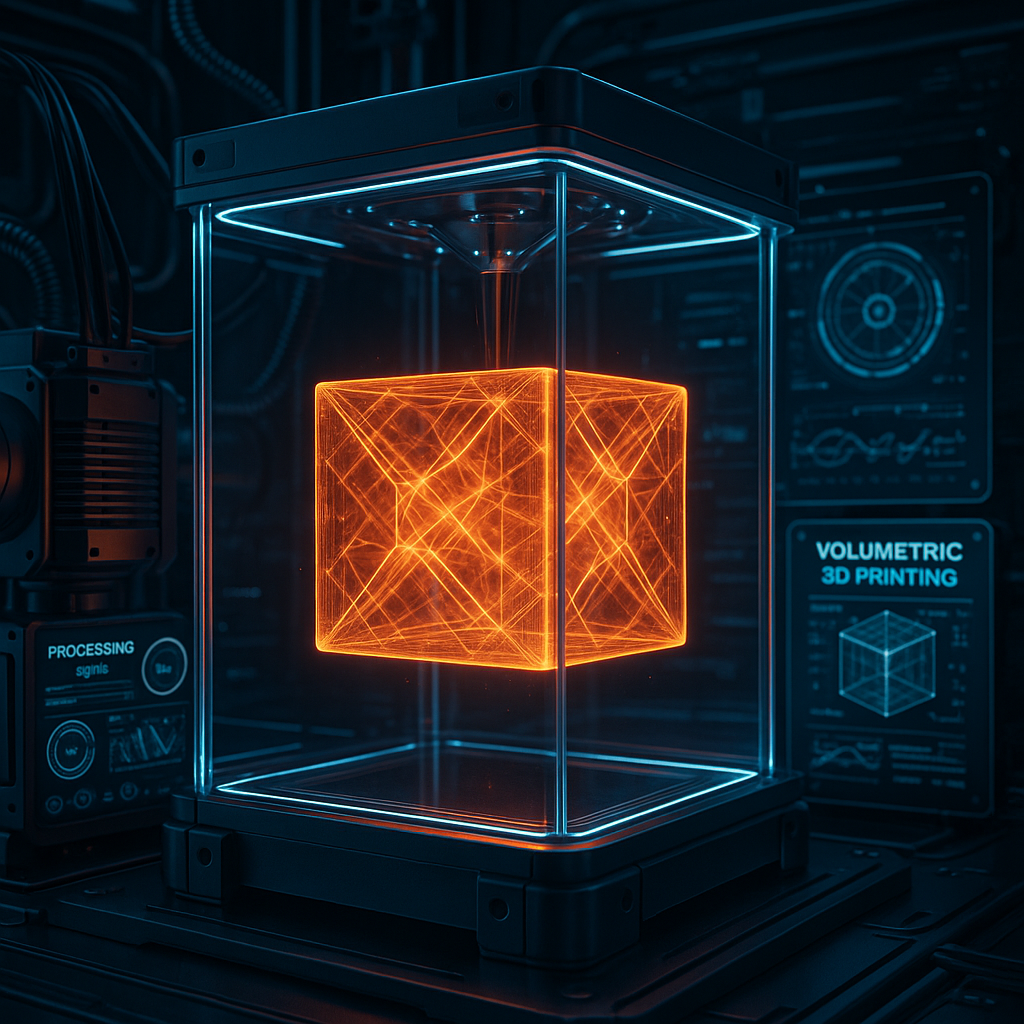

Volumetric 3D printing is gaining attention as a transformative technology in additive manufacturing, with potential to accelerate production and expand applications. Recent developments highlighted in The Growth Blueprint: The Path from 3D Printing to Injection Molding North in Carolina demonstrate how additive manufacturing continues to evolve alongside traditional methods like injection molding.

What Happened

While the referenced article primarily discusses the transition from 3D printing to injection molding in North Carolina, it indirectly underscores the ongoing innovation in additive manufacturing technologies, including volumetric 3D printing. This technique, distinct from layer-by-layer methods, constructs objects volumetrically in a single or few steps, drastically reducing build times. Although the article does not detail volumetric printing specifically, its inclusion in the broader additive manufacturing landscape signals growing interest in novel approaches that complement or enhance traditional manufacturing.

Why It Matters

Volumetric 3D printing represents a paradigm shift with the potential to overcome key limitations of conventional 3D printing, such as slow speed and anisotropic mechanical properties. By curing entire volumes simultaneously, it enables faster production cycles and potentially higher material homogeneity. This can accelerate prototyping, reduce time-to-market, and open new possibilities for complex geometries and biomedical applications. As manufacturers seek to integrate additive methods with established processes like injection molding, volumetric printing could serve as a critical bridge technology, enhancing flexibility and efficiency.

Technical Context

Traditional 3D printing technologies, such as fused deposition modeling (FDM) or stereolithography (SLA), build parts layer by layer, which can be time-consuming and introduce mechanical weaknesses at layer interfaces. Volumetric 3D printing, in contrast, uses techniques like computed axial lithography or tomographic reconstruction to cure resin volumes in a single exposure. This approach requires precise control of light projection and photopolymer chemistry to achieve accurate, defect-free parts. Key challenges include material formulation, resolution limits, and scaling up for larger parts. Current research focuses on optimizing photopolymers and refining optical systems to improve speed, accuracy, and material compatibility.

Near-term Prediction Model

Volumetric 3D printing is currently in the pilot stage, with several startups and research groups demonstrating proof-of-concept systems. Over the next 12 to 24 months, we anticipate gradual commercialization targeting niche markets such as medical devices, custom implants, and rapid prototyping where speed and complexity are critical. Adoption in mainstream manufacturing will depend on overcoming material and scale limitations and integrating volumetric printing into hybrid workflows with injection molding and CNC machining. The technology’s impact score is moderate to high (around 70/100) due to its disruptive potential, but confidence remains medium (about 60/100) given technical and market uncertainties.

What to Watch

- Advancements in photopolymer resins tailored for volumetric curing with enhanced mechanical properties and biocompatibility.

- Development of scalable volumetric printing systems capable of producing larger parts with consistent quality.

- Integration strategies combining volumetric printing with injection molding or subtractive methods for hybrid manufacturing.

- Regulatory approvals and certifications, especially in medical and aerospace sectors, that could drive adoption.

- Collaborations between traditional manufacturers and volumetric printing startups to accelerate commercialization.

In summary, volumetric 3D printing is poised to become a significant player in the additive manufacturing ecosystem, complementing established processes and enabling new applications. While challenges remain, ongoing innovation and strategic partnerships will likely unlock its full potential in the near future.