What Happened

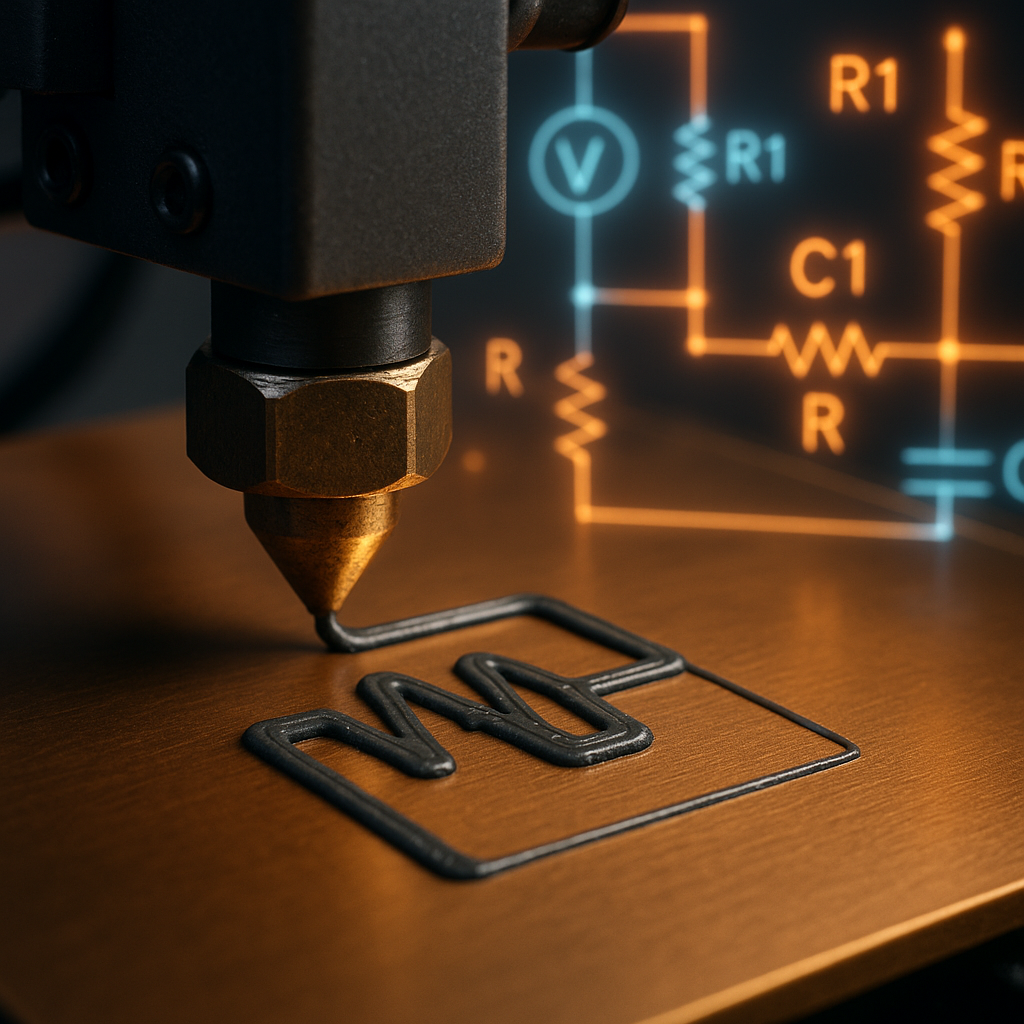

Researchers have demonstrated the ability to 3D print functional resistors directly using electrically conductive filament on a standard desktop 3D printer. This breakthrough, reported by 3DPrint.com, opens new possibilities for integrating electronics directly into 3D printed objects without additional assembly steps.

Why It Matters

Traditional electronics manufacturing often requires complex, multi-step processes to create resistors and other components, which are then integrated into devices. The ability to 3D print resistors on-demand using conductive filament simplifies this workflow, allowing designers and engineers to embed electronic functionality directly into printed parts. This capability is transformative for prototyping, custom electronics, wearable devices, and smart materials, where seamless integration and rapid iteration are critical.

Additionally, desktop 3D printers are widely accessible, so this advancement democratizes electronics fabrication, potentially enabling hobbyists, educators, and small businesses to create custom circuits without specialized equipment.

Technical Context

Conductive filaments typically consist of a polymer matrix blended with conductive fillers such as carbon black, graphene, or metal particles. These composites provide electrical conductivity but generally have higher resistivity compared to traditional metal conductors. The researchers leveraged this property to print resistor elements by controlling filament geometry and print parameters to achieve desired resistance values.

Key technical challenges include ensuring consistent filament conductivity, maintaining dimensional precision during printing, and managing the thermal and mechanical stability of the printed resistors. The desktop 3D printer used is a standard Fused Filament Fabrication (FFF) machine, demonstrating that no specialized hardware modifications are necessary.

Details such as the exact filament composition, the range of resistance values achievable, and the long-term stability of the printed resistors remain unspecified in the source. Further research is needed to characterize performance under various environmental conditions and electrical loads.

Near-term Prediction Model

In the next 12 to 24 months, we anticipate incremental improvements in conductive filament formulations and printer control software to enhance resistor performance and reproducibility. Commercially available conductive filaments will likely expand in variety and quality, catering to specific electrical properties. This will support rapid prototyping of embedded electronics in consumer and industrial applications.

However, widespread adoption for critical electronics manufacturing is expected to remain limited in the short term due to material limitations and reliability concerns. Instead, this technology will find niche applications in educational tools, wearable tech prototypes, and customized sensor integration.

What to Watch

- Development of standardized conductive filaments with predictable electrical properties.

- Advances in multi-material 3D printing that combine conductive and insulating filaments in a single print.

- Integration of printed resistors with other printed electronic components such as capacitors, sensors, and antennas.

- Long-term durability studies of printed resistors under mechanical stress, temperature variation, and humidity.

- Emergence of design software enabling seamless electronic circuit layout within 3D models.