What Happened

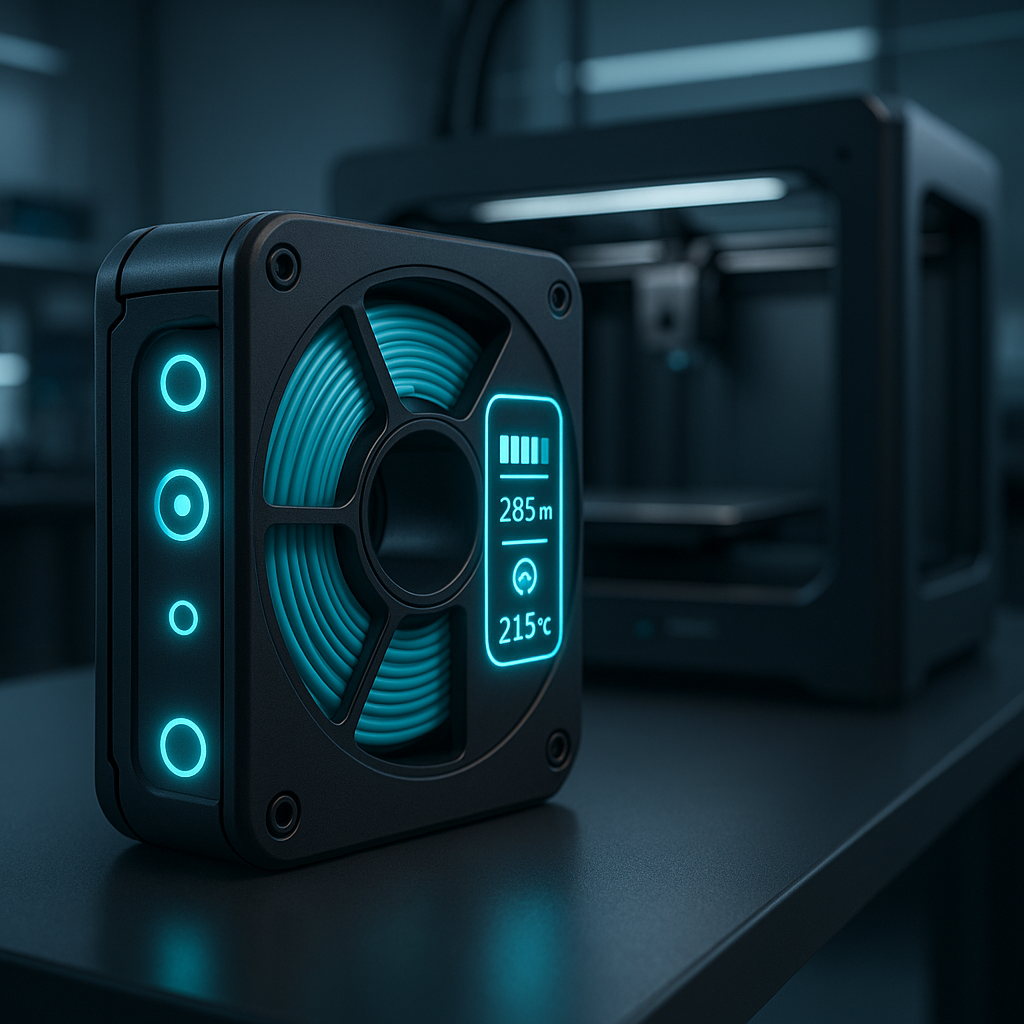

3D Printing Systems has unveiled an innovative smart filament cartridge system called The Bunker, as reported by 3DPrint.com on August 16, 2016. This system integrates smart technology directly into the filament cartridge, aiming to improve the management, monitoring, and overall user experience of 3D printing materials.

Why It Matters

The introduction of The Bunker smart filament cartridge system addresses several persistent challenges in the 3D printing community, particularly around filament handling and print reliability. Filament quality and availability are critical factors that influence print success, but users often face issues such as filament moisture absorption, misfeeds, or running out mid-print. By embedding intelligence into the filament cartridge, The Bunker promises enhanced tracking of filament usage, condition, and compatibility with printers, potentially reducing failed prints and material waste.

Moreover, as the 3D printing industry moves towards more automated and user-friendly solutions, smart filament cartridges represent a step forward in integrating IoT principles into additive manufacturing. This can pave the way for more connected, responsive 3D printing ecosystems that optimize material usage and maintenance.

Technical Context

While specific technical details about The Bunker system remain limited in the public domain, the concept of a smart filament cartridge generally involves embedding sensors and communication modules within the filament spool housing. These components can monitor parameters such as filament diameter consistency, remaining length, humidity exposure, and temperature. The cartridge may communicate wirelessly with the 3D printer’s control system or a cloud platform, enabling real-time data exchange.

Such integration requires overcoming challenges related to power supply for sensors, data accuracy, and ensuring the cartridge remains compatible with a broad range of printers. The Bunker’s design likely incorporates a robust housing to protect the filament and electronics, as well as standardized interfaces for ease of use.

Near-term Prediction Model

Given the current information, The Bunker smart filament cartridge system appears to be transitioning from pilot to early commercial stages. Adoption will initially be driven by professional and industrial users who prioritize print reliability and workflow automation. Over the next 12 to 24 months, we anticipate incremental improvements in cartridge sensor accuracy, interoperability, and cost reduction.

Wider adoption in consumer and prosumer markets will depend on printer manufacturers’ willingness to support smart cartridges and the development of open standards. If successful, smart filament cartridges could become a standard accessory, significantly reducing filament-related print failures and enabling predictive maintenance.

What to Watch

- Integration with 3D printers: How quickly major 3D printer manufacturers adopt or support The Bunker or similar smart filament cartridges.

- Standardization efforts: Development of industry standards for smart filament communication protocols and data formats.

- Sensor technology advances: Improvements in sensor miniaturization, accuracy, and power efficiency within cartridges.

- User feedback and adoption rates: Real-world performance reports and acceptance by both industrial and consumer users.

- Expansion into bio-embedded or multi-material filaments: Potential for smart cartridges to manage complex or bioactive materials requiring precise environmental control.

In summary, 3D Printing Systems’ Bunker smart filament cartridge system represents a meaningful innovation in the 3D printing materials space by embedding intelligence directly into the filament supply. While still early in its market presence, it signals a broader trend towards smarter, more integrated additive manufacturing workflows.