What Happened

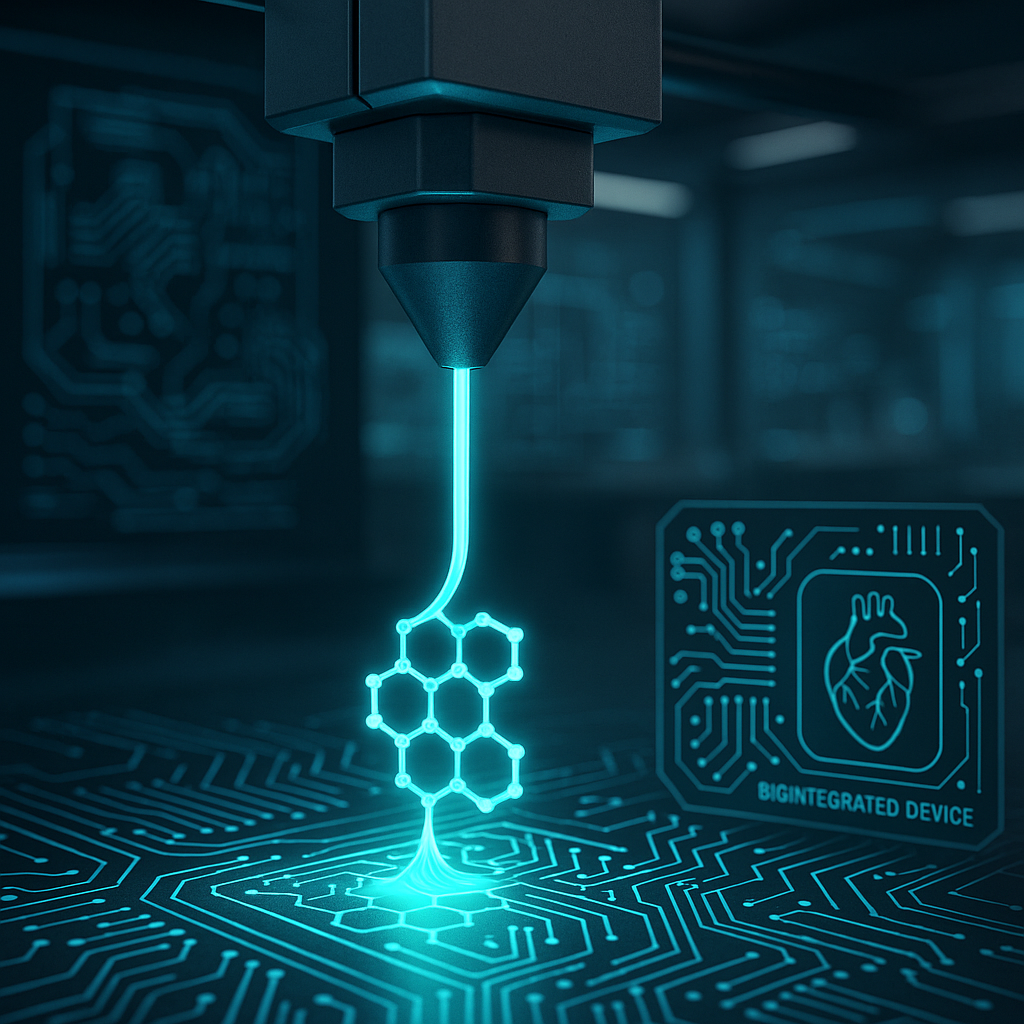

Recent developments in graphene-based 3D printing materials are gaining attention as detailed in a Graphene-Info article published in July 2024. The article introduces graphene 3D printing and highlights the current market status of graphene-enhanced filaments, particularly conductive filaments that enable new functionalities in printed objects. This marks an evolution beyond traditional polymer filaments toward smart and bio-embedded materials with electrical conductivity and improved mechanical properties.

Why It Matters

The integration of graphene into 3D printing filaments addresses a critical demand for multifunctional materials capable of embedding sensing, actuation, or bio-interfacing directly into printed designs. Conductive filaments are essential for printed electronics, wearable devices, and biomedical implants that require electrical pathways without assembly. Graphene’s exceptional conductivity, mechanical strength, and biocompatibility make it uniquely suited for these applications, potentially revolutionizing sectors from healthcare to flexible electronics.

Technical Context

Conductive filaments traditionally rely on carbon black, carbon nanotubes, or metal particles embedded in polymer matrices. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, surpasses these fillers by offering higher electrical conductivity and mechanical reinforcement at lower loadings. However, dispersing graphene uniformly within thermoplastic polymers for 3D printing remains challenging due to agglomeration and viscosity effects.

Recent advances have focused on optimizing graphene functionalization and compounding techniques to produce filaments compatible with FDM (Fused Deposition Modeling) printers. These filaments maintain printability while achieving conductivity levels sufficient for low-power electronics and sensor applications. The balance between graphene content, mechanical flexibility, and filament extrusion quality is an active research area.

Bio-embedding potential arises from graphene’s biocompatibility and ability to interface with biological tissues electrically. This opens pathways for 3D-printed implants or scaffolds that can monitor healing or deliver electrical stimulation, integrating smart functionality directly into medical devices.

Near-Term Prediction Model

Graphene conductive filaments are currently transitioning from pilot to early commercial stages. Over the next 12 to 24 months, expect incremental improvements in filament consistency, printer compatibility, and application-specific formulations. The impact score for this technology is high, around 75, reflecting its transformative potential balanced against technical and manufacturing hurdles.

Confidence in near-term growth is moderate (around 65) due to challenges in scaling production, quality control, and establishing standardized testing protocols. Key risks include variability in graphene quality, cost barriers compared to traditional conductive fillers, and limited end-user awareness or expertise in designing for conductive 3D printing.

What to Watch

- Development of industry standards for graphene filament electrical and mechanical performance.

- Emergence of turnkey 3D printers optimized for conductive filament extrusion and printing.

- New bio-embedded device prototypes demonstrating clinical or wearable applications.

- Partnerships between graphene material suppliers and 3D printing hardware manufacturers.

- Regulatory guidance on biocompatibility and safety for medical-grade graphene filaments.

- Cost reduction strategies through improved graphene synthesis and filament production methods.

Overall, graphene-enhanced conductive filaments represent a promising frontier in smart and bio-embedded 3D printing materials. Continued innovation and collaboration across materials science, engineering, and biomedical fields will be critical to unlocking their full potential.