As highlighted in Tom’s Hardware’s 2025 filament review, the 3D printing industry is witnessing a growing emphasis on advanced materials, particularly smart filaments that integrate dynamic properties. This frontier analysis explores what smart filaments are, why their emergence is significant, and how they fit into the evolving landscape of 3D printing technology.

What Happened

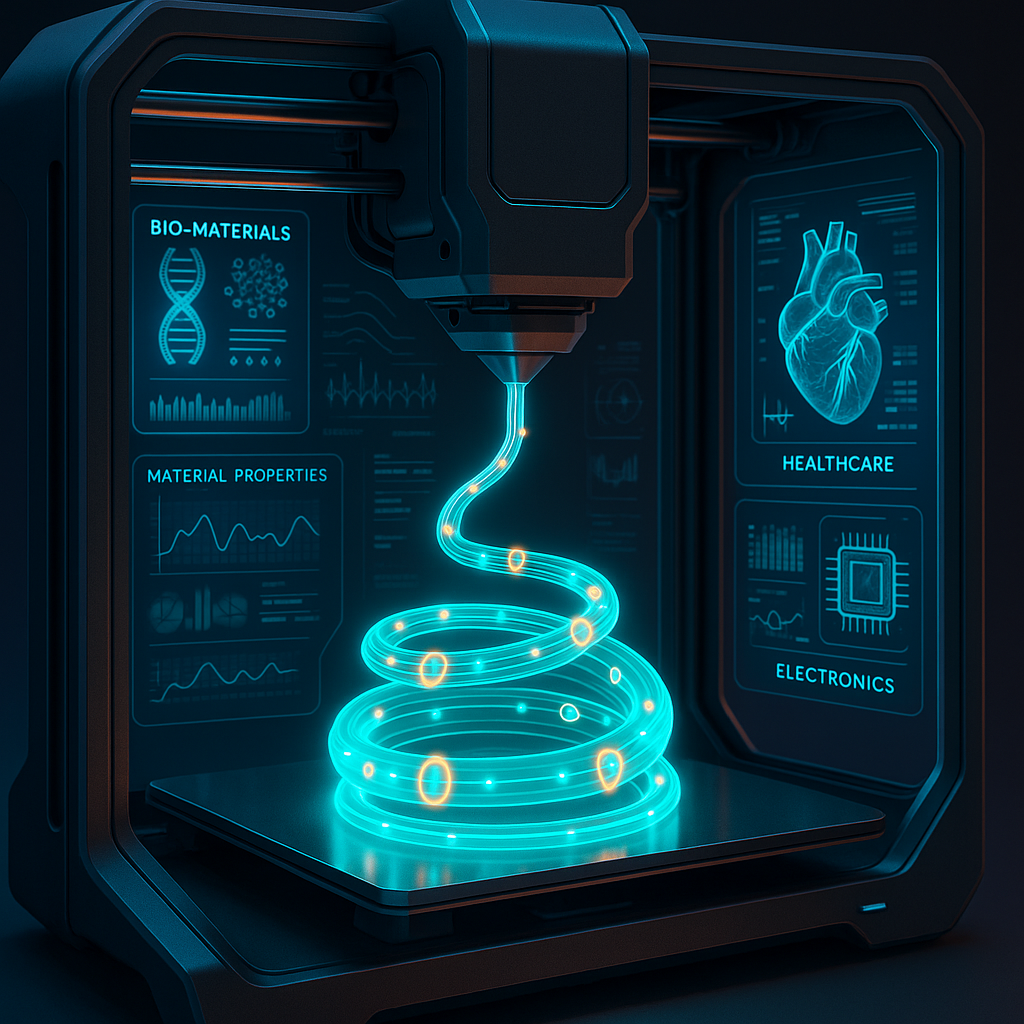

Tom’s Hardware’s recent coverage of the best filaments for 3D printing in 2025 underscores a rising interest in filaments that go beyond traditional thermoplastics. Among these, smart filaments—materials embedded with sensors, conductive elements, or responsive compounds—are gaining attention. Although the article primarily focuses on filament performance and compatibility, it hints at the increasing availability and experimentation with smart materials designed to interact with environmental stimuli or enable embedded functionality within printed objects.

Why It Matters

The integration of smart filaments into mainstream 3D printing workflows has the potential to transform additive manufacturing from a purely structural fabrication process into a platform for creating intelligent, multifunctional products. This evolution could impact industries ranging from healthcare, where bio-embedded filaments might enable patient-specific implants with sensing capabilities, to consumer electronics, where printed components could self-monitor or adapt. The move toward smart filaments aligns with broader trends in materials science emphasizing multifunctionality and embedded intelligence.

Technical Context

Smart filaments typically incorporate materials such as conductive polymers, piezoelectric compounds, thermochromic pigments, or bioactive agents. These additives provide the printed object with capabilities like electrical conductivity, temperature sensitivity, or biological interaction. The challenge lies in balancing these functionalities with printability, mechanical strength, and layer adhesion. Currently, many smart filaments remain in the pilot or early commercial stages, with ongoing research addressing issues such as filament stability, extrusion consistency, and integration with standard FDM/FFF printers.

Moreover, bio-embedded materials represent a specialized subset of smart filaments where living cells or biomolecules are incorporated into the printing matrix. This area is still largely experimental, requiring precise control over printing conditions to maintain biological viability. Advances in this domain could enable breakthroughs in tissue engineering, biosensors, and customized medical devices.

Near-Term Prediction Model

Over the next 12 to 24 months, we anticipate incremental but steady growth in the availability and adoption of smart filaments. As manufacturers refine formulations to improve reliability and ease of use, these materials will become more accessible to prosumers and small businesses. However, widespread adoption in industrial settings may require further validation of long-term durability and integration with automated quality control systems.

We expect that initial applications will focus on prototyping and niche products where embedded sensing or responsiveness adds clear value. For instance, hobbyists might create temperature-sensitive models or conductive traces embedded directly into parts, while medical device developers explore smart implants with integrated monitoring.

What to Watch

- Development of standardized testing protocols for smart filament performance, including mechanical, electrical, and biological metrics.

- Emergence of hybrid printers or upgraded extruders designed explicitly for multi-material or bio-embedded filament processing.

- Collaborations between material scientists and 3D printer manufacturers to optimize filament-printer compatibility.

- Regulatory developments around bio-embedded 3D printed devices, which could influence market readiness.

- Community-driven projects and open-source initiatives pushing the boundaries of smart filament applications.

While detailed specifications and commercial availability of many smart filaments remain limited in the public domain, the trajectory outlined by Tom’s Hardware and corroborated by ongoing research suggests a vibrant future for these materials. Continued monitoring of industry announcements and academic publications will be essential to stay abreast of breakthroughs in this dynamic field.