What Happened

Recent market research highlighted by GlobeNewswire projects the global 3D printing filament market to exceed USD 5.85 billion by 2033, growing at a compound annual growth rate (CAGR) of 19.49%. This robust growth is fueled by innovations in smart filament technologies that embed sensing, responsive, and bio-interactive properties directly into 3D printable materials.

Why It Matters

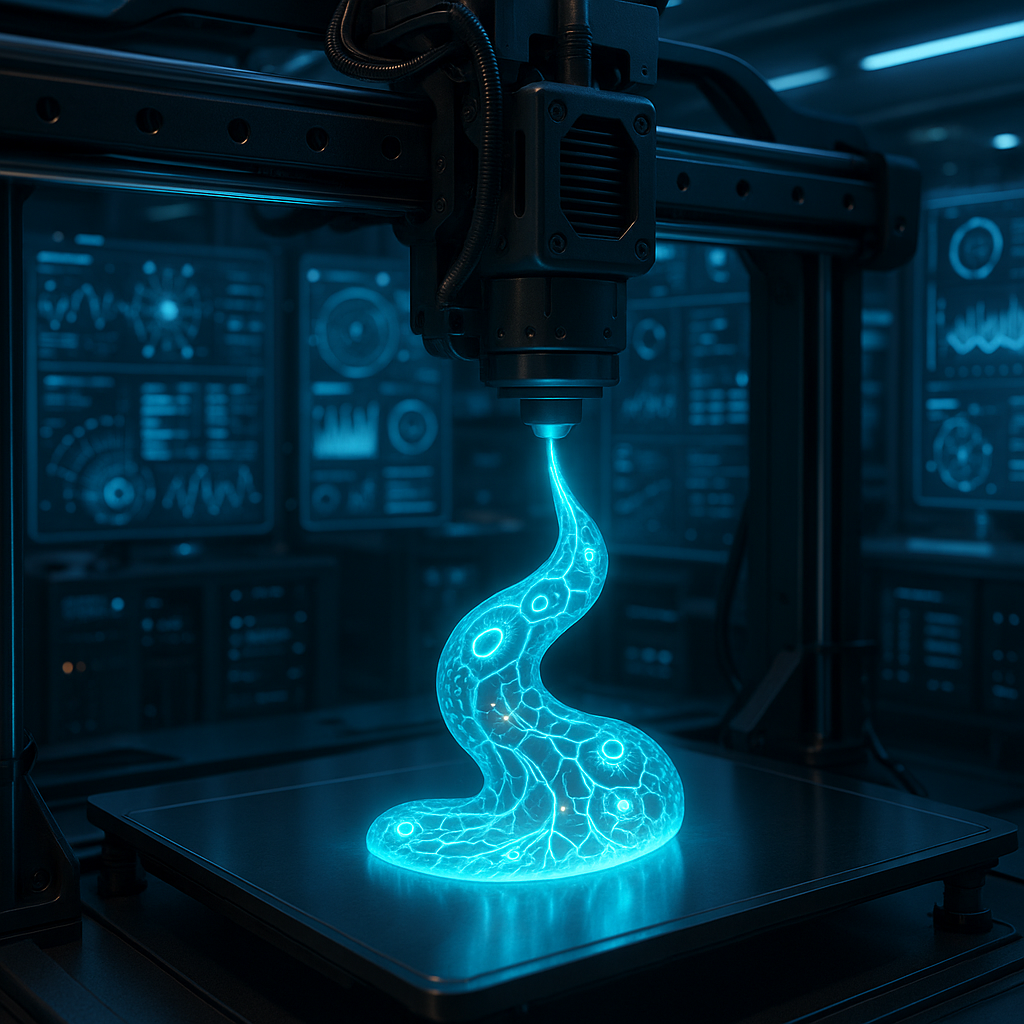

The surge in smart filament development represents a paradigm shift in additive manufacturing. Traditional filaments primarily offer structural or aesthetic functions. Smart filaments, however, integrate functionalities such as conductivity, shape memory, thermal responsiveness, and biological compatibility. This enables the fabrication of parts and prototypes that can self-monitor, adapt to environmental changes, or interact biologically, expanding the application scope from industrial parts to wearable electronics and biomedical devices.

As industries from aerospace to healthcare increasingly demand multifunctional components, the ability to print with smart filaments reduces assembly complexity and cost, accelerates prototyping cycles, and opens new frontiers in personalized manufacturing. The market growth forecast underscores how these materials are transitioning from niche R&D projects into mainstream commercial adoption.

Technical Context

Smart filaments are composite or blended materials that incorporate functional additives or engineered polymers. Examples include conductive filaments embedded with carbon nanotubes or graphene for electronic circuits, shape memory polymers that respond to heat stimuli, and bio-embedded filaments containing living cells or biomolecules for tissue engineering.

Developing these filaments poses challenges such as maintaining printability, ensuring uniform dispersion of functional agents, and preserving the smart properties post-printing. Advances in polymer chemistry, nanomaterial synthesis, and extrusion technology have progressively addressed these issues. Moreover, standard FDM (Fused Deposition Modeling) and SLA (Stereolithography) printers have been adapted or optimized to handle these specialized materials without compromising mechanical properties.

Despite progress, many smart filament formulations remain under pilot or early commercial stages, with ongoing research focusing on enhancing durability, biocompatibility, and multi-functionality.

Near-Term Prediction Model

Given the current trajectory, smart filaments are expected to move from pilot to broader commercial stages within the next 24 to 36 months. Market demand will likely accelerate as more end-users recognize the cost and performance benefits of embedded functionality. Early adopters in medical devices, automotive sensors, and consumer electronics will drive initial volume, encouraging filament producers to scale up manufacturing capacity.

However, adoption rates will vary by sector depending on regulatory approvals, material certification, and integration with existing manufacturing workflows. Continued collaboration between material scientists, printer manufacturers, and end-users will be crucial to overcoming these barriers.

What to Watch

- Development of new bio-embedded filaments capable of printing living tissues or organ-like structures.

- Standardization efforts and certification protocols for smart filaments in regulated industries such as healthcare and aerospace.

- Emergence of multi-functional filaments combining several smart properties, e.g., conductive and shape-memory capabilities in a single material.

- Advances in printer hardware specifically designed to optimize printing with smart filaments, including temperature control and extrusion precision.

- Collaborations between filament manufacturers and software providers to enable design tools that leverage smart filament functionalities.

While the market size projections are promising, specific details on the segmentation of smart filament contributions within the overall filament market remain unavailable. Tracking these developments will be essential to fully understand the impact of smart filaments on the additive manufacturing landscape.