Recent advances in collagen bioresins have marked a significant breakthrough in 3D bioprinting, with volumetric printing techniques—especially tomographic printing—emerging as transformative technologies in this space. This synthesis article explores the implications of these developments, situating them within the technical context of volumetric printing, assessing their near-term outlook, and identifying key areas to watch.

What Happened

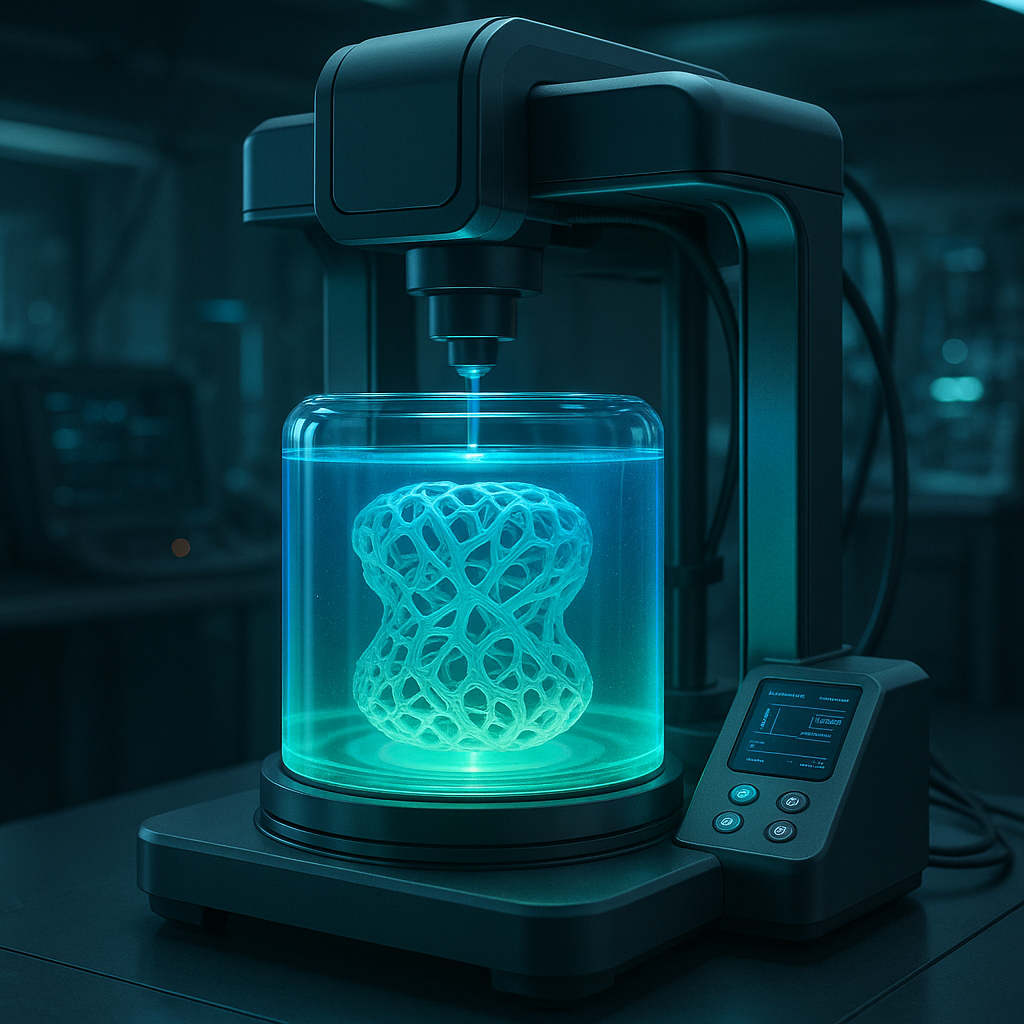

AZoOptics recently highlighted the development of collagen bioresins tailored for 3D bioprinting applications. These bioresins exhibit properties that make them highly compatible with volumetric printing methods, including tomographic printing, which constructs complex 3D structures by projecting light patterns through a rotating volume of resin. This approach contrasts with traditional layer-by-layer 3D printing by enabling rapid, volumetric solidification of materials in a single step.

The integration of collagen-based bioresins with tomographic printing techniques represents a convergence of material science and advanced additive manufacturing. While the article focuses primarily on the bioresins themselves, it implicitly underscores the growing relevance of volumetric printing modalities in overcoming the limitations of conventional extrusion or vat polymerization bioprinting.

Why It Matters

Bioprinting has long grappled with challenges related to speed, resolution, and biological compatibility. Conventional layer-wise printing methods can be time-consuming and may induce mechanical stresses detrimental to cell viability. Volumetric printing, particularly tomographic printing, offers a paradigm shift by enabling rapid fabrication of complex, cell-laden structures with high spatial fidelity and reduced print times.

Collagen, as the most abundant protein in the extracellular matrix of human tissues, is a highly desirable material for bioprinting due to its biocompatibility and ability to support cell adhesion and growth. The advancement of collagen bioresins optimized for volumetric printing could accelerate the production of functional tissue constructs for regenerative medicine, drug testing, and disease modeling.

Technical Context

Volumetric printing methods, including tomographic printing, utilize computed light projections to polymerize photosensitive resins within a rotating container, creating complex 3D forms in seconds to minutes. This approach bypasses the mechanical layering steps of traditional 3D printing, reducing shear stress on embedded cells and enabling more isotropic mechanical properties.

However, volumetric printing demands highly specialized resins that balance optical clarity, photosensitivity, mechanical robustness, and biological compatibility. Collagen bioresins must be engineered to polymerize efficiently under the specific wavelengths and intensities used in tomographic setups while maintaining cell viability and function.

Currently, the detailed formulation and photopolymerization kinetics of these collagen bioresins remain underreported, as does their performance in vivo or in clinical settings. Moreover, integration with living cells and vascularization strategies present ongoing challenges.

Near-term Prediction Model

Given the current state of research and the nascent commercialization of volumetric bioprinting, it is reasonable to place this technology at the Pilot maturity stage. Within the next 18 to 24 months, we anticipate accelerated development of collagen bioresins optimized for tomographic printing, alongside pilot demonstrations of functional tissue constructs.

The impact score is estimated at 75 out of 100, reflecting the high potential to disrupt current bioprinting workflows and improve clinical translation. Confidence in this trajectory is moderate, around 65 out of 100, due to uncertainties related to scale-up, regulatory approval, and biological integration.

What to Watch

- Publication of detailed studies on the photopolymerization properties and biocompatibility of collagen bioresins tailored for volumetric printing.

- Demonstrations of volumetrically printed, cell-laden tissue constructs with functional vascularization or mechanical properties mimicking native tissues.

- Advancements in tomographic printing hardware that improve resolution, scalability, and multi-material printing capabilities.

- Regulatory developments and clinical trial initiations involving volumetrically printed bioprinted tissues.

- Collaborations between material scientists, biologists, and additive manufacturing engineers to optimize integrated bioprinting workflows.

In summary, the fusion of collagen bioresin innovations with volumetric printing techniques like tomographic printing heralds a promising frontier in 3D bioprinting. While challenges remain, the rapid fabrication capabilities and biological advantages of this approach could significantly accelerate the translation of bioprinted tissues from the lab to clinical applications.