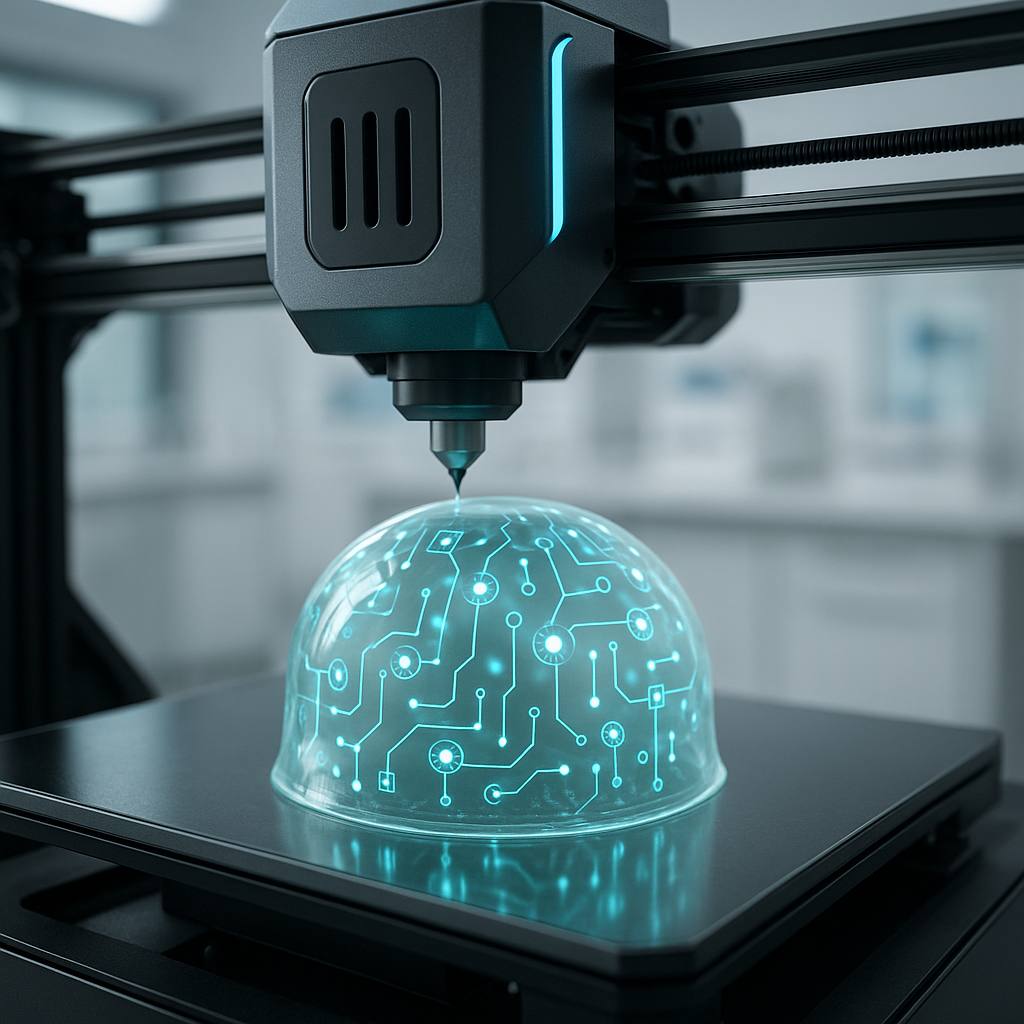

In a significant stride toward the future of additive manufacturing, Purdue University researchers have pioneered methods to integrate embedded sensors directly into 3D printed materials, effectively adding a “fourth dimension” to traditional 3D printing processes. This advancement, detailed in their recent publication Adding a fourth dimension to 3D printing, marks a leap toward smart and bio-embedded materials that can sense, react, and adapt to their environments.

What Happened

Purdue’s research team has developed a novel approach to embed sensors within 3D printed structures during the printing process itself, rather than attaching them post-production. This method enables the creation of multifunctional materials that combine structural integrity with sensing capabilities, potentially transforming static parts into dynamic, responsive systems. Although the exact types of sensors and materials used were not fully disclosed in the summary, the innovation points to a convergence of additive manufacturing and embedded electronics.

Why It Matters

Embedding sensors directly into 3D printed objects unlocks a new paradigm of smart materials with applications spanning healthcare, aerospace, robotics, and wearable technology. For example, bio-embedded sensors could monitor physiological conditions in real time when integrated into prosthetics or implants, while aerospace components with embedded sensors could provide continuous structural health monitoring, improving safety and maintenance efficiency. This integration reduces the need for external sensor attachment, lowering weight and complexity while enhancing durability and functionality.

Technical Context

Traditional 3D printing focuses on fabricating objects layer by layer using polymers, metals, or ceramics. However, these objects are typically passive, lacking the ability to interact with their environment. The concept of “4D printing” introduces the dimension of time or responsiveness, where printed materials change properties or behavior post-fabrication. Purdue’s approach advances this by embedding sensing elements—likely microelectromechanical systems (MEMS) or flexible electronics—within the print. This requires overcoming challenges such as material compatibility, sensor durability during printing, and maintaining sensor functionality within complex geometries.

Currently, embedding sensors involves multi-material printing techniques or pause-and-insert methods, which can be time-consuming and prone to alignment issues. Purdue’s innovation presumably streamlines this process, although specifics on the printing technology (e.g., fused deposition modeling, stereolithography, or direct ink writing) and sensor types remain unspecified.

Near-term Prediction Model

Given the research nature of this breakthrough, the maturity stage of embedded sensor 3D printing is at the R&D phase, with pilot demonstrations likely within 12 to 24 months. Commercial adoption may follow within 3 to 5 years, contingent on scalability, cost reduction, and integration with existing manufacturing workflows. The impact score is high (around 80/100) due to the transformative potential across multiple industries, but confidence remains moderate (approximately 65/100) because of technical and manufacturing challenges yet to be fully addressed.

What to Watch

- Publication of detailed methodologies and sensor integration techniques by Purdue or other research groups.

- Development of compatible multi-material 3D printers capable of embedding functional sensors without compromising print quality.

- Emergence of pilot projects applying embedded sensor materials in medical devices, aerospace components, or robotics.

- Standardization efforts for testing and validating embedded sensor durability and performance.

- Collaborations between sensor manufacturers and additive manufacturing companies to commercialize integrated solutions.

While the promise is immense, the path to widespread adoption depends on overcoming material science challenges, ensuring sensor reliability under mechanical stresses, and developing cost-effective production methods. Continued research and cross-disciplinary innovation will be critical to realizing the full potential of smart, bio-embedded 3D printed materials.