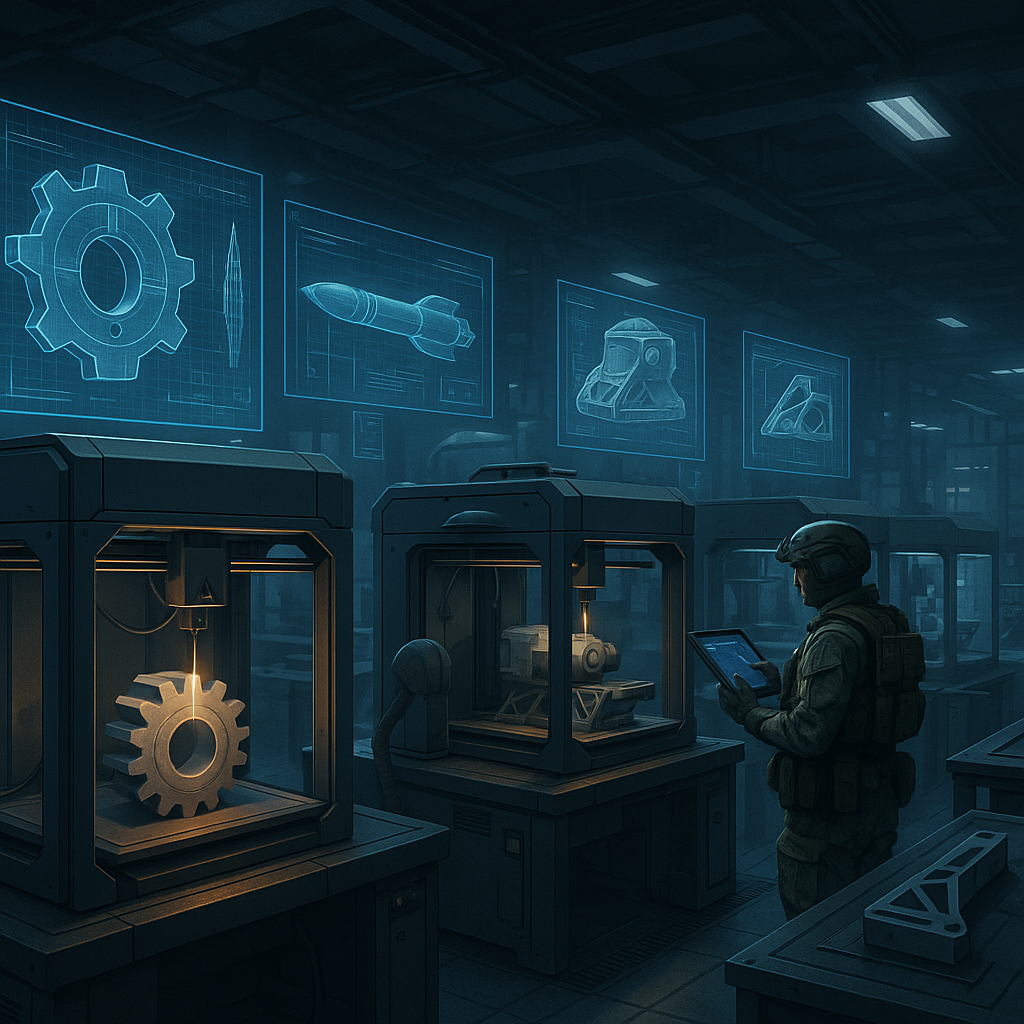

ASTM International has recently joined a strategic initiative aimed at leveraging additive manufacturing (AM) technologies to enhance defense manufacturing capabilities, as reported by Design News. This collaboration marks a significant step toward integrating distributed manufacturing and on-demand production methods into defense supply chains, aiming to increase agility, resilience, and operational readiness.

What Happened

ASTM International, a globally recognized standards organization, has aligned itself with an initiative focused on harnessing additive manufacturing to support defense applications. The initiative is designed to explore and implement AM technologies that can produce critical parts and components on demand, closer to the point of need. While specific details about the partners involved or the scope of the program have not been fully disclosed, this move signals ASTM’s commitment to developing standards and frameworks that enable reliable and secure distributed manufacturing for defense.

Why It Matters

The defense sector faces unique challenges in logistics and supply chain management, particularly when it comes to sourcing spare parts and components in remote or contested environments. Traditional manufacturing and inventory models often involve long lead times and vulnerabilities to disruption. By leveraging additive manufacturing and distributed production networks, defense organizations can reduce dependency on centralized suppliers and physical inventories.

This initiative’s importance lies in its potential to transform how military equipment is maintained and repaired. Digital inventory models supported by AM allow for on-demand production of parts, reducing storage costs and improving availability. ASTM’s involvement is critical because standardized processes and materials are essential to ensure that 3D printed parts meet stringent defense quality and safety requirements.

Technical Context

Additive manufacturing encompasses a range of technologies that build parts layer by layer from digital designs. In defense applications, AM is particularly valuable for producing complex geometries, lightweight components, and customized parts that are otherwise difficult or slow to manufacture. However, challenges remain in qualification, repeatability, and certification of printed parts.

Distributed manufacturing refers to a decentralized production model where manufacturing capabilities are spread across multiple locations rather than centralized factories. In combination with digital inventory systems—where part designs are stored digitally and transmitted as needed—this approach enables rapid, localized production.

ASTM International’s role typically involves developing consensus standards that define material properties, testing methods, and process controls. These standards are foundational to ensuring that parts produced via AM in distributed environments meet defense-grade performance and reliability criteria.

Near-Term Prediction Model

Over the next 12 to 24 months, we expect the initiative to progress through pilot deployments and validation phases. Early efforts will likely focus on identifying priority parts for AM production, developing standardized test protocols, and establishing secure digital inventory frameworks. The initiative may also explore cybersecurity aspects to protect digital design files and manufacturing processes.

While full-scale operational adoption across all defense branches may take longer, initial successes could demonstrate measurable improvements in supply chain responsiveness and cost efficiency. ASTM’s standards development will be iterative, responding to feedback from pilot programs and technological advancements.

What to Watch

- Publication of new ASTM standards specific to additive manufacturing for defense applications.

- Announcements of pilot projects or partnerships between defense agencies and AM service providers.

- Advances in digital inventory management platforms enabling secure and efficient distributed manufacturing.

- Technological breakthroughs in AM materials and processes that meet or exceed military specifications.

- Cybersecurity frameworks developed to protect digital manufacturing assets in distributed environments.

In summary, ASTM International’s engagement in this additive manufacturing initiative represents a pivotal development in the evolution of distributed manufacturing for defense. By establishing rigorous standards and fostering collaboration, this effort promises to enhance the agility and resilience of military supply chains through digital inventory and on-demand production capabilities.