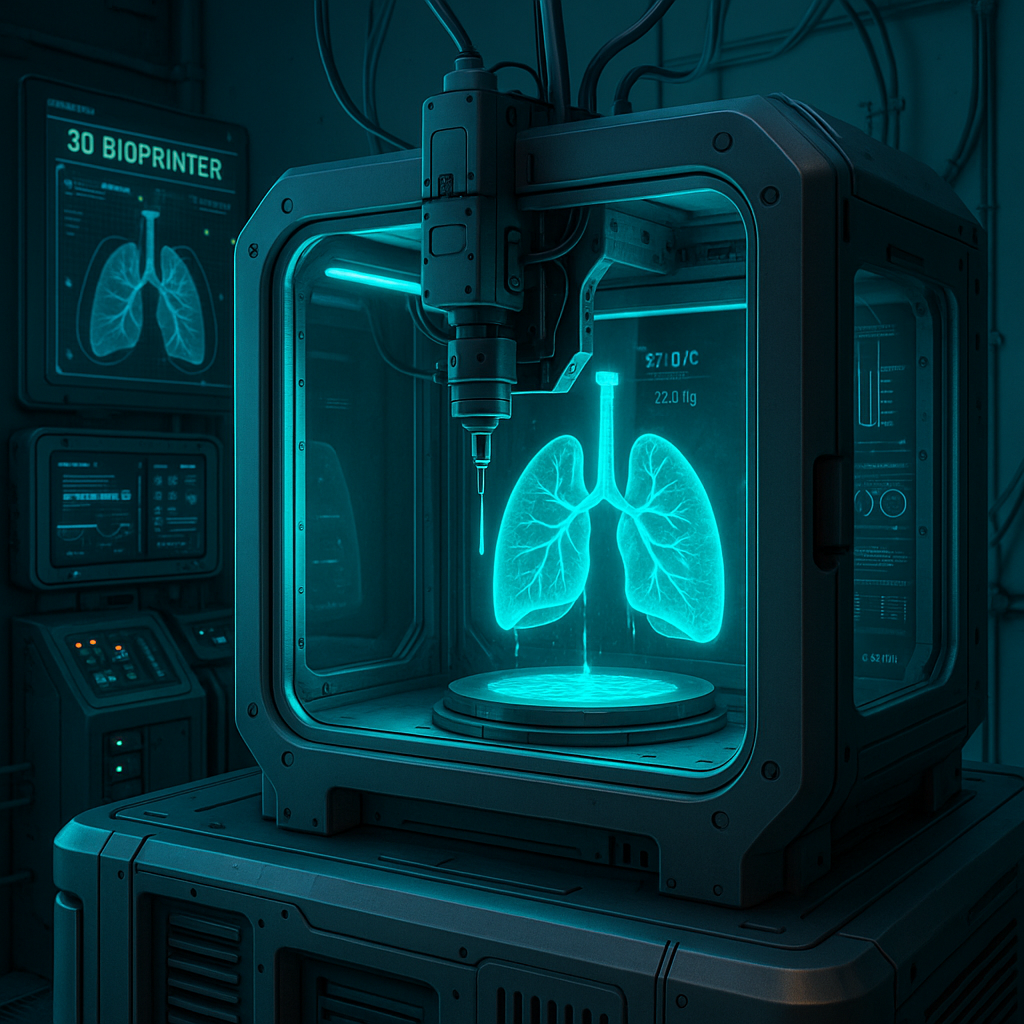

Researchers at Texas A&M University have achieved a remarkable milestone in the field of bio-embedded 3D printing by successfully fabricating living lung cells layer by layer in extreme environments, as reported in Texas A&M Stories on November 24, 2025. This breakthrough demonstrates the potential to manufacture living lung tissue constructs in conditions previously considered prohibitive for cell viability and functionality.

What Happened

The Texas A&M team developed a novel bioprinting process capable of layering living lung cells within an engineered matrix under extreme environmental conditions. While the article does not detail the exact environmental parameters, “extreme” suggests challenges such as temperature fluctuations, low oxygen levels, or mechanical stresses that typically compromise cell survival during printing. By overcoming these barriers, the researchers have shown that it is possible to build complex, functional lung tissue constructs layer by layer, potentially mimicking the natural architecture of lung alveoli and airways.

Why It Matters

This advance is significant for several reasons. First, lung diseases remain a leading cause of morbidity and mortality worldwide, and the shortage of donor organs limits transplantation options. Creating living lung tissue via 3D printing could revolutionize regenerative medicine by providing patient-specific implants or models for drug testing. Second, the ability to print viable cells in extreme environments expands the versatility and application scope of bioprinting technologies, potentially enabling manufacturing in non-traditional settings such as remote clinics or even space missions. Third, this work pushes the boundaries of bio-embedded materials, integrating living systems directly into 3D printed constructs rather than relying on inert scaffolds.

Technical Context

Bioprinting living cells layer by layer requires precise control over multiple factors: cell viability, bioink composition, printing parameters, and post-printing maturation. The lung’s delicate and complex structure, with thin alveolar walls and intricate vascular networks, poses unique challenges. Traditional bioprinting often requires tightly controlled lab environments to maintain cell health. Texas A&M’s approach presumably incorporates innovative bioinks or protective matrices that shield cells from environmental stressors during printing. Additionally, advanced printer hardware modifications may regulate local microenvironments, such as humidity, gas exchange, and temperature, to sustain cell function. While the article does not specify the bioink formulations or printer design, this research likely builds on emerging trends in multi-material printing and microfluidic control.

Near-Term Prediction Model

Currently, this technology appears to be in the advanced R&D phase, with promising proof-of-concept results but limited information on scalability or clinical readiness. Over the next 12 to 24 months, we anticipate further refinement of printing protocols and bioink chemistries to enhance tissue complexity and durability. Pilot studies may emerge demonstrating functional lung tissue patches or in vitro models for respiratory disease research. Commercialization is likely beyond a 3-year horizon due to regulatory hurdles, the need for extensive validation, and manufacturing challenges. However, the impact score is high given the potential to transform lung regenerative therapies and biofabrication capabilities. Confidence remains moderate due to the novelty and technical complexity.

What to Watch

- Publication of detailed methodologies and bioink formulations enabling cell survival in extreme environments.

- Demonstrations of functional lung tissue constructs with vascularization and gas exchange capabilities.

- Collaborations or funding announcements targeting clinical translation or commercialization pathways.

- Advances in bioprinter hardware that support environmental controls tailored for living cell printing.

- Regulatory developments around bio-embedded 3D printed tissues, particularly for lung applications.

In summary, Texas A&M’s work marks a notable step forward in the bio-embedded 3D printing domain, showcasing the feasibility of fabricating living lung cells under challenging conditions. While many technical details remain undisclosed, this breakthrough sets the stage for future innovations in regenerative medicine and smart material integration.