What Happened

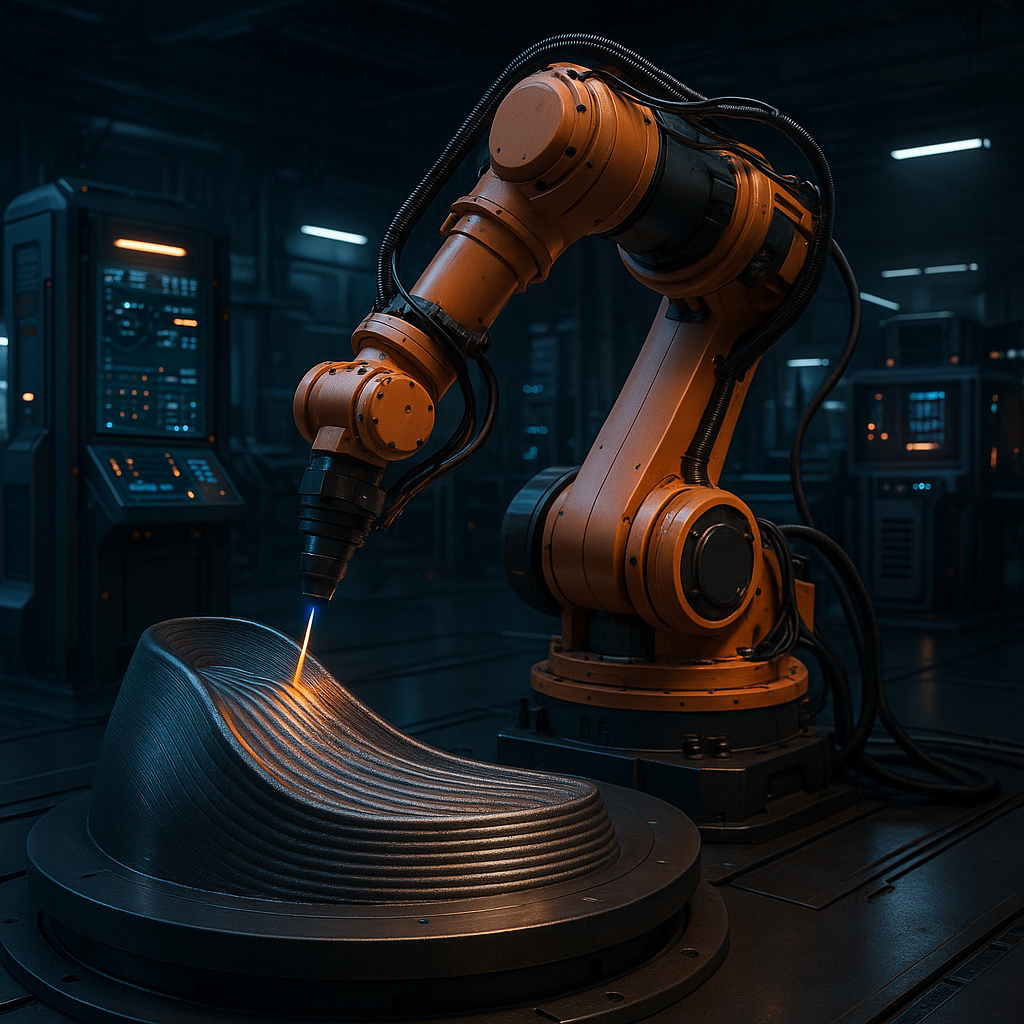

Siemens recently highlighted advancements in additive manufacturing within high-precision industrial environments, as detailed in their article Additive manufacturing in a cutting (edge) environment. Their work focuses on integrating multi-axis additive manufacturing techniques into industrial cutting-edge applications to improve precision, efficiency, and part complexity.

Why It Matters

Multi-axis additive manufacturing represents a significant evolution beyond traditional layer-by-layer 3D printing. By enabling deposition along multiple axes, Siemens’ approach allows for the creation of complex geometries with improved mechanical properties and reduced post-processing. This is especially crucial in cutting-edge industrial environments where precision and material performance are paramount. The ability to print on non-planar surfaces and adjust deposition angles dynamically can lead to stronger, lighter, and more functional parts, potentially transforming sectors such as aerospace, automotive, and tooling.

Technical Context

Traditional additive manufacturing methods typically operate on a fixed planar (2.5D) layer-by-layer basis, which imposes limitations on surface finish, mechanical anisotropy, and geometric complexity. Siemens is pushing the frontier by leveraging multi-axis additive manufacturing, which involves moving the print head or the build platform along multiple rotational and translational axes. This non-planar deposition technique enables continuous printing on curved or angled surfaces, improving layer adhesion and mechanical strength.

While the exact technical specifications and hardware configurations Siemens employs are not fully disclosed, the integration of multi-axis additive manufacturing within cutting-edge environments likely involves advanced motion control systems, real-time process monitoring, and software capable of complex toolpath generation. These components are essential to manage the increased complexity of multi-axis trajectories and ensure consistent material deposition.

Near-Term Prediction Model

Given Siemens’ industrial scale and ongoing research, multi-axis additive manufacturing is currently in the Pilot stage, moving towards commercial adoption within 12 to 24 months. The impact score is high (around 80/100) due to the potential to disrupt existing manufacturing workflows and enable new part designs. Confidence remains moderate (around 70/100) because of challenges related to hardware complexity, process stability, and integration with existing production lines.

What to Watch

- Hardware advancements: Developments in multi-axis motion systems and print heads that can reliably operate under industrial conditions.

- Software and control algorithms: Improvements in toolpath planning and real-time feedback systems to handle complex geometries and materials.

- Material compatibility: Expansion of materials suitable for multi-axis additive processes, including metals and composites.

- Industrial adoption: Case studies and pilot projects demonstrating tangible benefits in aerospace, automotive, and tooling sectors.

- Standardization and certification: Progress in establishing quality standards and certifications for multi-axis additive manufactured parts.

While Siemens’ article provides a valuable glimpse into the potential of multi-axis additive manufacturing, many technical details and performance benchmarks remain undisclosed. Continued observation of Siemens’ announcements and pilot implementations will be critical in assessing the technology’s trajectory.

No listings found.