What Happened

In a recent development highlighted by 3D Adept Media, Nanoe and Orano have embarked on a collaborative venture to 3D print anti-corrosion materials. This partnership marks a significant step in applying advanced materials science to additive manufacturing processes, particularly within the realm of corrosion resistance. While specific technical details remain limited in the public domain, the collaboration signals a convergence of expertise in materials innovation and 3D printing technology.

Why It Matters

The integration of anti-corrosion materials into 3D printing processes is a notable advancement with broad industrial implications. Corrosion is a pervasive challenge across sectors such as energy, aerospace, and infrastructure, where material degradation can lead to costly maintenance and safety concerns. By enabling the direct 3D printing of anti-corrosion materials, Nanoe and Orano are potentially transforming how protective coatings and components are fabricated.

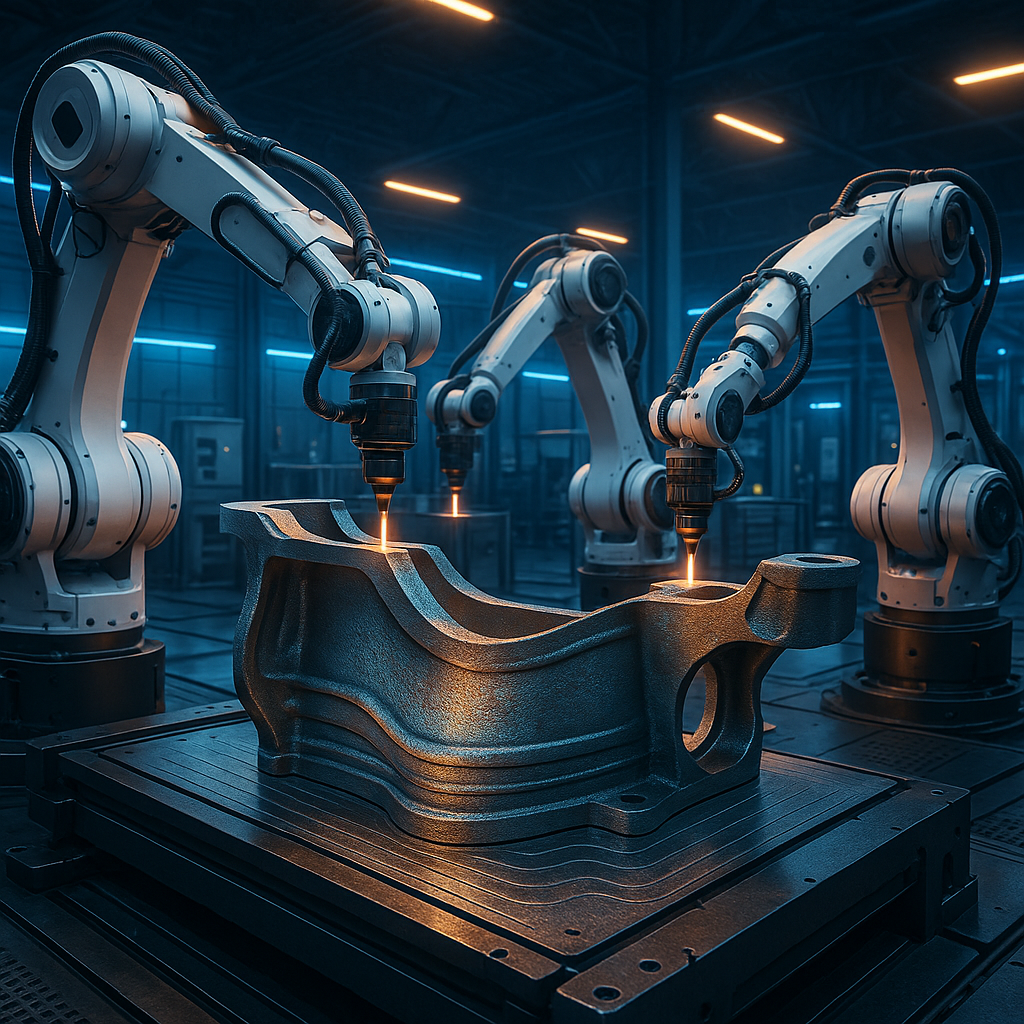

Moreover, this collaboration embodies the principles of collaborative printing or swarm manufacturing, where multiple entities or systems work synergistically to optimize production. The ability to print specialized materials collaboratively could lead to enhanced customization, reduced lead times, and improved material performance tailored to specific environmental conditions.

Technical Context

3D printing with functional materials like anti-corrosion compounds requires precise control over material composition, deposition methods, and curing processes. Nanoe and Orano’s partnership likely leverages expertise in chemical formulation and additive manufacturing technologies, possibly including powder bed fusion or material extrusion methods adapted for corrosion-resistant polymers or composites.

Collaborative printing frameworks often involve networked printers or integrated systems that coordinate to fabricate complex parts or multi-material assemblies. In this context, printing anti-corrosion materials collaboratively might mean distributing print tasks among machines specialized in different materials or processes, ensuring optimal layering and bonding for superior protective properties.

However, the exact nature of the collaborative printing approach—whether it involves multiple printers working in parallel, hybrid manufacturing techniques, or integrated material synthesis—is not yet fully disclosed. Understanding these technical specifics will be critical to assessing scalability and industrial viability.

Near-term Prediction Model

Given the current information, this technology appears to be transitioning from research and development towards pilot-scale demonstrations. The maturity stage can be classified as Pilot, with an estimated time horizon of 12 to 24 months before broader commercial adoption in targeted industries.

The impact score is projected at 75 out of 100, reflecting significant potential to disrupt corrosion mitigation practices through additive manufacturing. Confidence in this forecast is moderate at 65 out of 100, due to limited public technical details and the inherent challenges of scaling novel materials in 3D printing.

What to Watch

- Technical disclosures or whitepapers detailing the material formulations and printing methodologies used by Nanoe and Orano.

- Demonstrations or pilot projects showcasing real-world applications, particularly in sectors vulnerable to corrosion.

- Advancements in collaborative printing infrastructures that enable multi-material and multi-machine coordination for complex protective components.

- Regulatory and certification progress for 3D printed anti-corrosion parts, which will influence industrial adoption.

- Competitive developments from other companies focusing on functional material 3D printing and swarm manufacturing strategies.

In summary, the Nanoe and Orano collaboration represents a frontier in combining specialized materials with collaborative 3D printing approaches. While many technical details remain to be disclosed, the initiative highlights a promising direction for additive manufacturing to address longstanding industrial challenges like corrosion through innovative material and process integration.