Recent coverage by Leesburg Daily Commercial highlights the rising influence of top 3D printing service suppliers in driving global manufacturing innovation. Among the most promising technological advances is volumetric 3D printing, a transformative approach that is beginning to redefine the boundaries of additive manufacturing.

What Happened

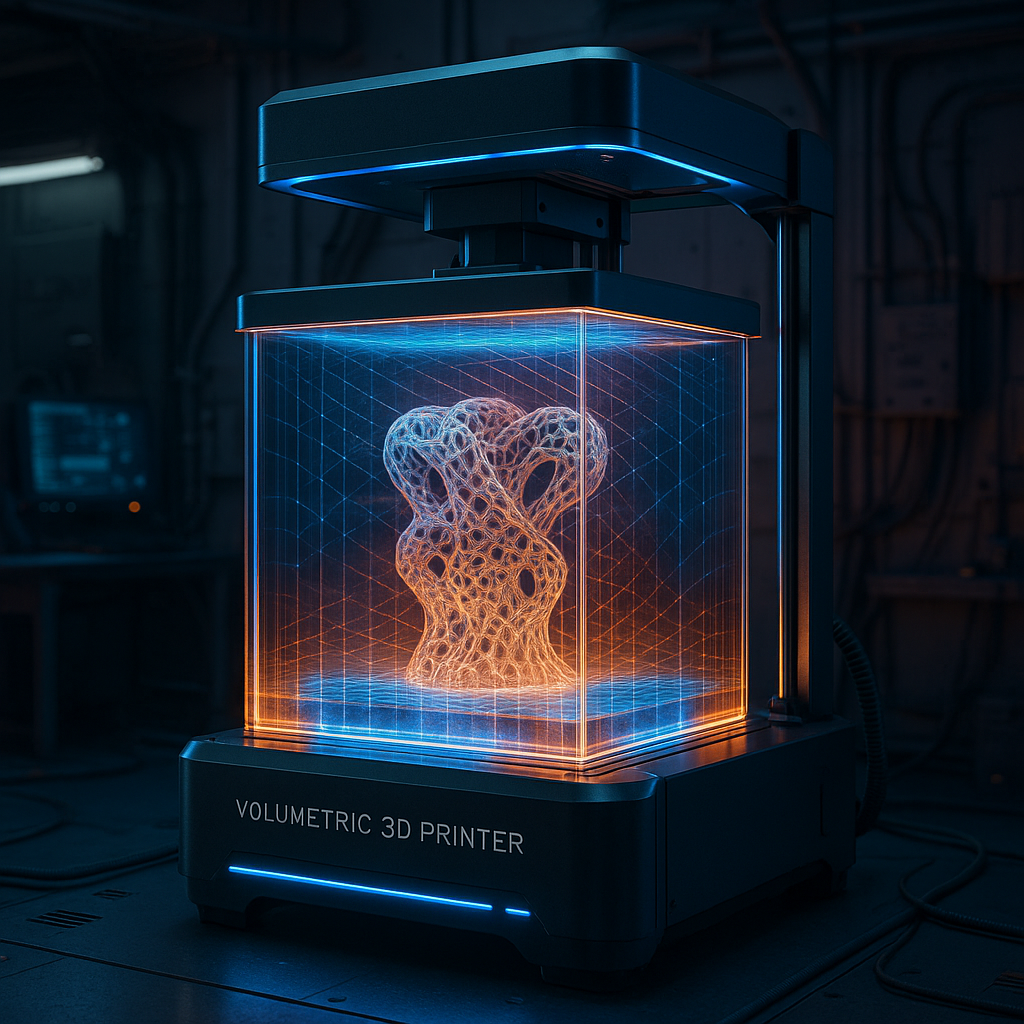

Leading 3D printing service suppliers are increasingly investing in volumetric 3D printing technologies, signaling a shift toward faster and more complex production capabilities. While traditional layer-by-layer 3D printing methods continue to dominate, volumetric printing is emerging as a viable alternative that can create entire objects in a single curing step, leveraging light or other energy sources to solidify resin volumes simultaneously. This advancement is gaining traction among manufacturers seeking to accelerate production speed and improve material properties.

Why It Matters

The significance of volumetric 3D printing lies in its potential to overcome key limitations of conventional additive manufacturing. Traditional methods often involve slow, sequential layering processes that can limit throughput and introduce anisotropic mechanical properties due to layer interfaces. Volumetric printing addresses these issues by enabling rapid fabrication of complex geometries with isotropic strength, reducing production times from hours to minutes or even seconds in some cases. For industries such as aerospace, medical devices, and automotive manufacturing, this could mean faster prototyping, more efficient small-batch production, and entirely new design possibilities.

Technical Context

Volumetric 3D printing typically employs techniques such as computed axial lithography (CAL), where a rotating volume of photosensitive resin is illuminated with dynamic light patterns from multiple angles. The resin polymerizes in the targeted 3D shape, forming the object in one continuous step. This contrasts with vat photopolymerization or material extrusion methods that build objects layer-by-layer. The technology requires precise control over light projection, resin chemistry, and volumetric reconstruction algorithms to achieve high resolution and accuracy.

Current challenges include optimizing resin formulations for faster curing and mechanical performance, improving system scalability for larger build volumes, and refining the computational models that drive light patterning. Additionally, post-processing steps and surface finish quality are areas under active development to meet industrial standards.

Near-Term Prediction Model

Given the growing interest from top service suppliers and ongoing R&D efforts, volumetric 3D printing is expected to transition from pilot projects to early commercial applications within the next 12 to 24 months. Initial adoption will likely focus on niche markets requiring rapid turnaround and complex internal geometries, such as biomedical implants or custom tooling. Broader industrial uptake will depend on improvements in material diversity, system cost reduction, and integration with existing manufacturing workflows.

Investment in volumetric printing startups and partnerships between technology developers and service bureaus will accelerate this maturation process. However, widespread replacement of traditional 3D printing technologies is not anticipated in the immediate future, as volumetric methods complement rather than supplant existing approaches.

What to Watch

- Advancements in resin chemistry that enable faster curing times and enhanced mechanical properties.

- Development of larger-scale volumetric printing systems capable of producing bigger parts without sacrificing resolution.

- Emergence of new software algorithms for more precise and faster volumetric light patterning.

- Strategic collaborations between volumetric printing technology firms and established 3D printing service suppliers.

- Regulatory developments and certification standards impacting medical and aerospace applications.

While many technical details and commercial strategies remain under wraps, the trajectory of volumetric 3D printing suggests it will become a key player in the additive manufacturing landscape. Stakeholders should monitor these developments closely to leverage the unique advantages this technology offers.