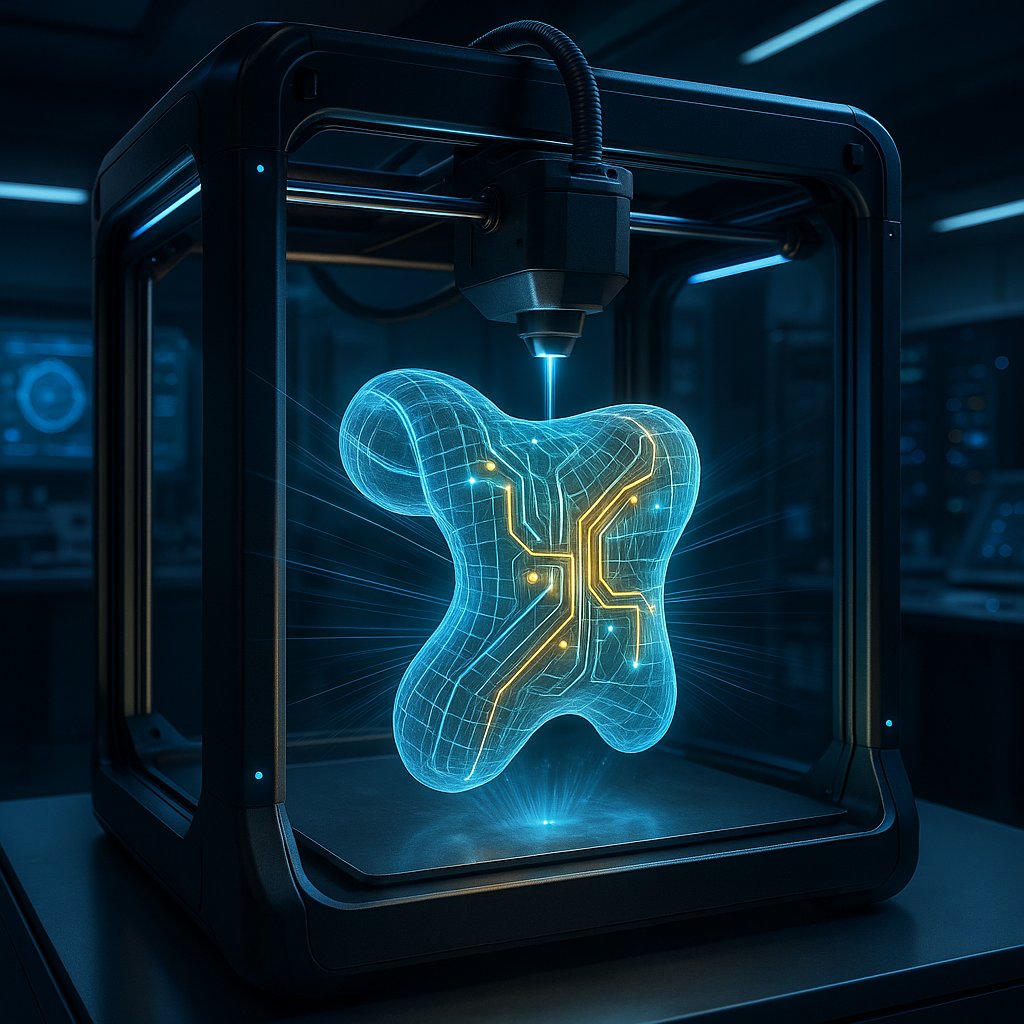

In a significant advancement for additive manufacturing, researchers have unveiled a volumetric 3D printing breakthrough that could revolutionize the production of next-generation medical devices and stretchable electronics. Detailed in a UT News article published on June 30, 2025, this development highlights the growing potential of volumetric 3D printing technology to fabricate complex, flexible, and functional components rapidly and with high precision.

What Happened

Researchers at the University of Texas have demonstrated a novel volumetric 3D printing technique that enables the creation of intricate, stretchable electronic devices and advanced medical implants in a single, continuous process. Unlike traditional layer-by-layer 3D printing methods, volumetric printing cures an entire 3D object simultaneously by projecting light patterns into a photosensitive resin. This approach drastically reduces print times and allows for the fabrication of complex geometries that were previously difficult or impossible to produce.

The reported breakthrough focuses on optimizing the printing process and materials to produce devices that combine mechanical flexibility with electronic functionality. While exact technical details remain limited in the source article, it is clear that the team has advanced both the hardware and photopolymer chemistry to meet the stringent demands of biomedical and wearable electronic applications.

Why It Matters

This breakthrough is significant for several reasons. First, volumetric 3D printing’s ability to rapidly produce complex shapes without the constraints of layer-by-layer deposition can dramatically accelerate prototyping and manufacturing cycles. This is especially critical in medical device production, where customization and speed can directly impact patient outcomes.

Second, the integration of stretchable electronics with volumetric printing opens new avenues for wearable health monitors, implantable devices, and soft robotics. These devices require materials that can endure mechanical deformation while maintaining electrical performance—a challenging combination for conventional manufacturing.

Finally, the convergence of volumetric 3D printing with advanced materials engineering represents a step toward more sustainable and scalable production methods. By minimizing waste and reducing assembly steps, this technology could lower costs and environmental impact in high-value manufacturing sectors.

Technical Context

Volumetric 3D printing, sometimes called computed axial lithography or tomographic volumetric printing, differs fundamentally from traditional additive manufacturing. Instead of building objects layer by layer, it projects dynamic light patterns from multiple angles into a rotating volume of photosensitive resin. The resin polymerizes where the cumulative light dose exceeds a threshold, solidifying the entire 3D shape at once.

This technique requires precise synchronization of light projection and resin chemistry to control polymerization kinetics and ensure dimensional accuracy. The challenge intensifies when printing functional materials such as conductive inks or elastomers needed for stretchable electronics.

The UT team’s breakthrough likely involves innovations in photoinitiators, resin formulations, and projection algorithms to balance curing speed, resolution, and mechanical properties. While the source does not specify the exact materials or hardware modifications, the mention of medical and electronic applications suggests a multidisciplinary approach combining materials science, optics, and bioengineering.

Near-term Prediction Model

Given the current stage of research and the typical timelines for translating academic breakthroughs into commercial products, volumetric 3D printing for stretchable electronics and medical devices is poised to move from R&D toward pilot projects within the next 12 to 24 months. Early adopters in medical device manufacturing and wearable electronics sectors are likely to conduct feasibility studies and small-scale production runs to validate performance and regulatory compliance.

As the technology matures, we can expect incremental improvements in material diversity, printing resolution, and device integration capabilities. This will gradually expand volumetric printing’s applicability beyond niche prototypes to broader commercial manufacturing, potentially within 3 to 5 years.

What to Watch

- Material Innovations: Advances in photopolymer chemistry enabling biocompatibility, conductivity, and elasticity will be critical for practical device fabrication.

- Hardware Development: Improvements in projection systems, light modulation, and real-time process monitoring will enhance print fidelity and scalability.

- Regulatory Pathways: For medical applications, navigating FDA or equivalent regulatory approvals will be a key milestone affecting commercialization timelines.

- Collaborations and Commercialization: Partnerships between academia, industry, and startups focused on volumetric printing applications will accelerate market entry.

- Competitive Technologies: Monitoring competing additive manufacturing methods, such as multi-material inkjet printing or hybrid processes, will contextualize volumetric printing’s evolving role.

In conclusion, this volumetric 3D printing breakthrough reported by UT News represents a promising frontier in additive manufacturing with the potential to disrupt medical device and stretchable electronics industries. While some technical specifics remain to be disclosed, the demonstrated capability to produce complex, flexible, and functional devices rapidly marks a pivotal step forward. Continued innovation in materials, hardware, and regulatory strategy will determine how soon this technology transitions from laboratory novelty to mainstream manufacturing tool.