What Happened

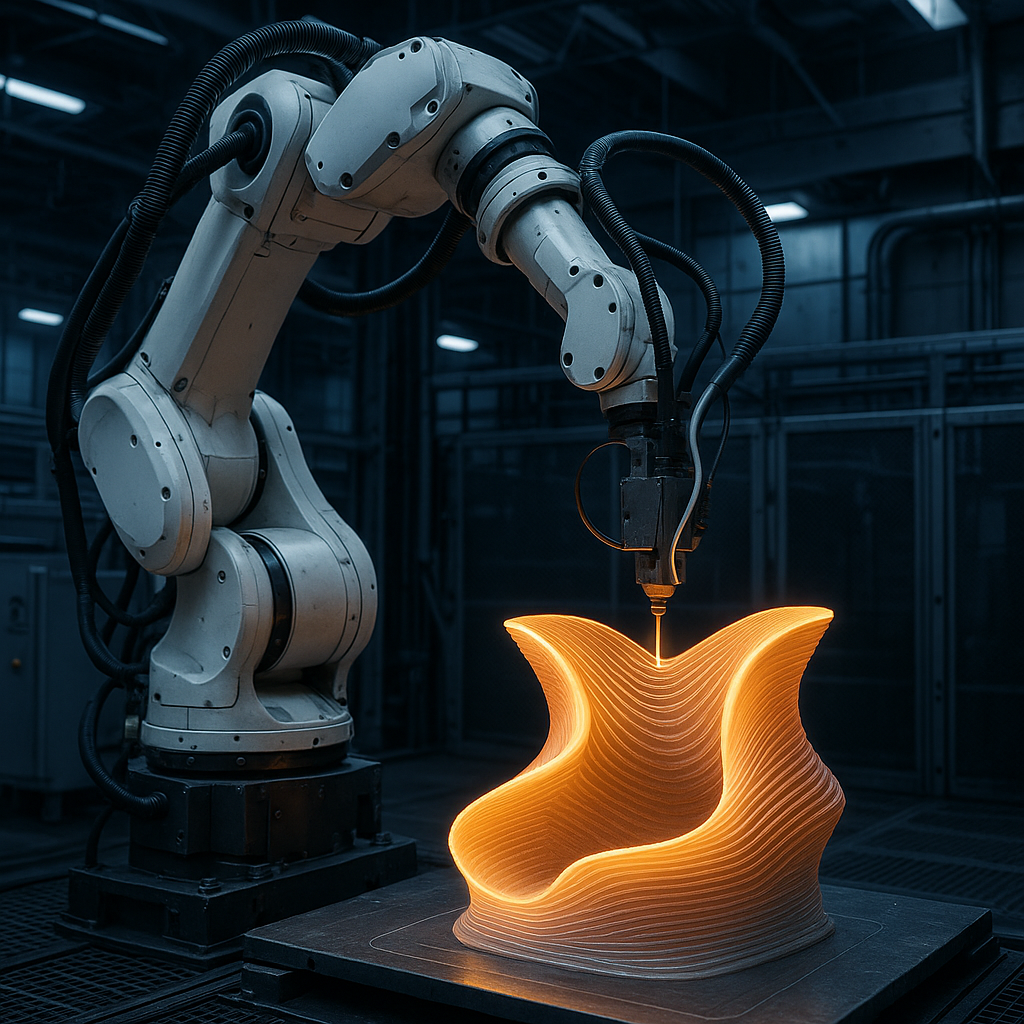

Recent developments in robotic arm 3D printing highlighted in the February 5, 2026 news briefs on 3DPrint.com signal growing momentum in non-planar and multi-axis additive manufacturing. While the article itself provides a broad overview of industry news, it points to an increasing emphasis on robotic arm-based 3D printing systems that can build complex geometries beyond traditional layer-by-layer planar constraints.

Why It Matters

Robotic arm 3D printing represents a significant leap in additive manufacturing capability. Unlike fixed gantry printers limited to planar slicing, robotic arms can maneuver the print head along multiple axes, enabling continuous, curved, and multi-directional deposition. This flexibility reduces the need for support structures, improves mechanical properties by aligning fibers or materials along stress paths, and opens new design freedoms for lightweight, functional parts. Such capabilities are critical for aerospace, automotive, and medical device sectors where performance and complexity are paramount.

Technical Context

Traditional fused filament fabrication (FFF) and stereolithography (SLA) printers operate predominantly in 3-axis Cartesian systems, depositing material layer by layer on flat planes. Robotic arm 3D printing systems typically add rotational axes (4, 5, or 6 degrees of freedom), allowing the print head to approach the part from varying orientations. This enables non-planar slicing strategies where layers follow curved surfaces or are deposited along continuous paths, reducing layer lines and anisotropy.

However, these systems require advanced path planning algorithms and real-time control to synchronize multi-axis movements accurately. Challenges include collision avoidance, maintaining consistent extrusion rates during complex motions, and integrating sensors for feedback. Material compatibility and print speed optimization also remain active research areas. The integration of virtual twins and digital simulation tools, as mentioned in the source, further supports refining these processes before physical printing.

Near-Term Prediction Model

Robotic arm 3D printing is currently transitioning from pilot to early commercial stages. While R&D efforts continue to address technical hurdles, several industrial players have deployed pilot systems for niche applications. Over the next 12 to 24 months, we expect incremental adoption in sectors demanding complex, high-value parts. The impact score is moderate to high (around 70) given the potential for design innovation and efficiency gains, but confidence remains medium (around 65) due to technical and cost barriers.

What to Watch

- Advances in multi-axis slicing software and real-time path correction algorithms.

- Material development tailored for robotic arm deposition, including composites and high-performance polymers.

- Case studies demonstrating mechanical property improvements and support reduction.

- Integration of virtual twins and AI-driven process optimization to enhance print reliability.

- Collaborations between robotic system manufacturers and 3D printing material suppliers.

- Expansion of use cases beyond prototyping into full-scale production.

While the source article from 3DPrint.com provides limited specific details on individual robotic arm printing projects, the overall industry signals a clear trajectory toward more sophisticated, multi-axis additive manufacturing platforms. Continued innovation in this frontier promises to reshape how complex parts are designed and manufactured.