What happened

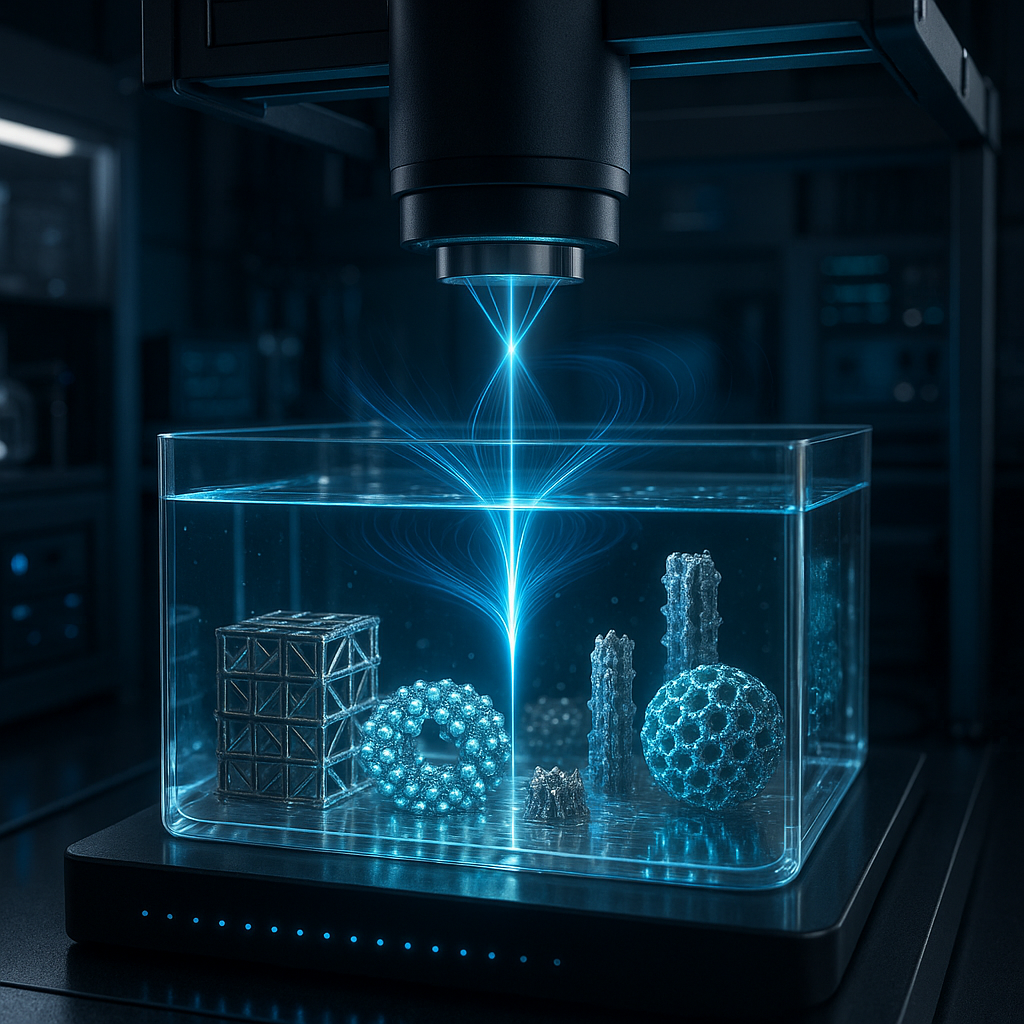

A recent breakthrough reported by 3D Printing Industry highlights an innovative optofluidic assembly method that enables volumetric 3D printing of microstructures composed of metals, oxides, and quantum dots. This approach leverages the interplay of light and fluid dynamics to fabricate complex three-dimensional microarchitectures not achievable with traditional layer-by-layer processes.

Why it matters

Volumetric 3D printing, unlike conventional additive manufacturing, builds entire volumes simultaneously, drastically reducing print times and enabling intricate internal geometries. The integration of metals, oxides, and quantum dots within these microstructures opens new horizons for multifunctional devices in electronics, photonics, and catalysis. This method addresses critical challenges in microfabrication, such as material versatility and resolution, potentially transforming sectors reliant on miniaturized components.

Technical context

Traditional 3D printing techniques often struggle with fabricating metal microstructures due to high melting points and complex post-processing requirements. Oxides and quantum dots add further complexity because of their distinct chemical and optical properties. The optofluidic assembly method combines precise light patterning with fluidic manipulation to orchestrate the spatial arrangement of diverse materials within a photosensitive medium. This volumetric approach bypasses the constraints of layer adhesion and anisotropy inherent in layer-by-layer printing.

While the exact parameters and mechanisms of the optofluidic process remain partially undisclosed, it likely involves dynamic modulation of light intensity and fluid flow to control the polymerization and assembly of embedded particles. This enables high-resolution microstructures with tailored compositions and functionalities. The method’s ability to incorporate quantum dots suggests potential for integrated optoelectronic components with enhanced performance.

Near-term prediction model

Currently positioned at the R&D stage, this technology is expected to progress into pilot applications within 18 to 24 months. Its impact score is estimated at 75 out of 100, reflecting substantial potential to disrupt microfabrication paradigms, though with moderate confidence (65%) due to unknown scale-up challenges and material compatibility issues.

Key risks include difficulties in scaling the process for larger volumes, ensuring uniformity across complex geometries, and integrating diverse materials without compromising structural integrity. Additionally, the stability and reproducibility of quantum dot incorporation need further verification to meet industrial standards.

What to watch

- Publication of detailed process parameters and demonstrations of scalability.

- Advances in material formulations compatible with optofluidic volumetric printing.

- Commercial pilot projects or partnerships with electronics and photonics manufacturers.

- Development of post-processing techniques to enhance mechanical and functional properties.

- Emerging applications leveraging multifunctional microstructures combining metals and quantum dots.

Overall, this optofluidic volumetric 3D printing method represents a promising frontier in additive manufacturing, with the potential to unlock new classes of microdevices and accelerate innovation across multiple industries.