What Happened

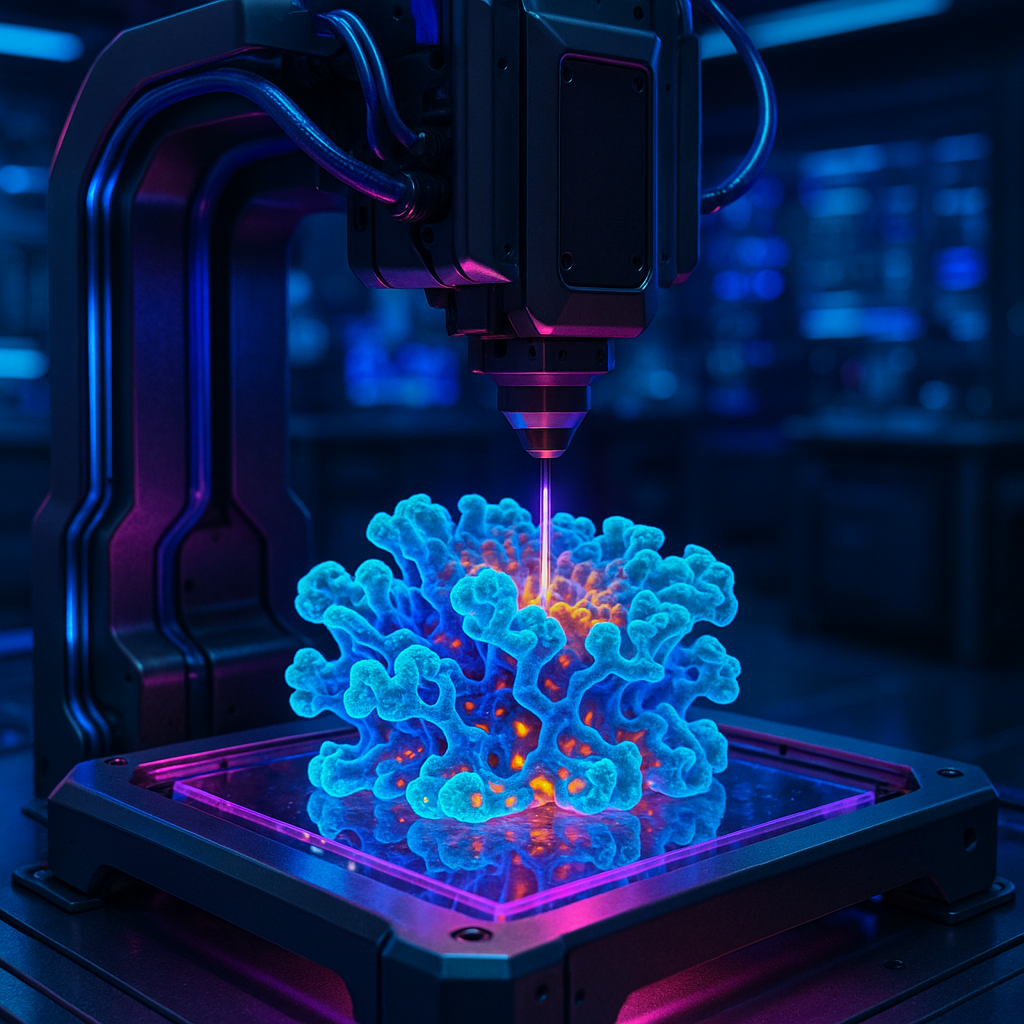

Recent research highlighted by Cambridge University Press & Assessment details advances in the synthesis of engineered proteins combined with three-dimensional (3D) printing techniques to create living materials. This emerging field integrates biological components directly into printed structures, enabling materials that are not only structurally functional but also biologically active and responsive.

Why It Matters

The convergence of engineered proteins with 3D printing of living materials represents a paradigm shift in material science and biofabrication. Unlike traditional inert materials, living materials can self-heal, adapt to environmental stimuli, and potentially perform complex biological functions such as sensing or catalysis. This opens new horizons for applications in healthcare, environmental remediation, and smart manufacturing. For example, bio-embedded implants could promote tissue regeneration, while environmentally responsive materials could dynamically interact with their surroundings.

Technical Context

At the core of this development is the ability to engineer proteins with precise molecular functions and incorporate them into printable bioinks. These bioinks contain living cells or biologically active components that survive the printing process and maintain functionality post-fabrication. The challenge lies in balancing printability, mechanical stability, and biological viability.

The research from Cambridge underscores progress in protein engineering techniques that allow for tailored interactions and assembly within 3D printed matrices. This includes designing proteins that can form stable hydrogels or scaffolds conducive to cell growth and activity. Additionally, advanced printing methods such as extrusion-based bioprinting or stereolithography are adapted to accommodate these sensitive biological materials.

However, many technical details remain undisclosed or under active investigation, such as long-term stability of living materials, scalability of production, and integration with existing manufacturing workflows.

Near-Term Prediction Model

Given current research momentum, the technology is positioned at the Pilot stage, where lab-scale prototypes demonstrate proof of concept but have yet to reach widespread commercial deployment. Within the next 24 to 36 months, we anticipate incremental advances in bioink formulations and printing techniques that improve robustness and reproducibility.

Early applications are likely to emerge in specialized biomedical devices, such as customized tissue scaffolds or biosensors, where regulatory pathways are clearer and functional benefits are compelling. Environmental applications, such as living filters or self-regenerating materials, may follow as the technology matures.

What to Watch

- Bioink Innovation: New protein designs and formulations that enhance printability and biological function.

- Printing Technology Advances: Adaptations in 3D printing hardware that improve cell viability and structural resolution.

- Long-Term Stability Studies: Research on durability and performance of living materials in real-world conditions.

- Regulatory Developments: Frameworks for approving bio-embedded medical devices and environmental materials.

- Cross-Disciplinary Collaborations: Partnerships between synthetic biology, materials science, and manufacturing industries.

In summary, the integration of engineered proteins and 3D printing to fabricate living materials is an exciting frontier with transformative potential. While technical and regulatory challenges remain, the foundational research outlined by Cambridge University Press & Assessment signals a promising trajectory toward smart, bio-embedded materials that could redefine multiple industries.