What Happened

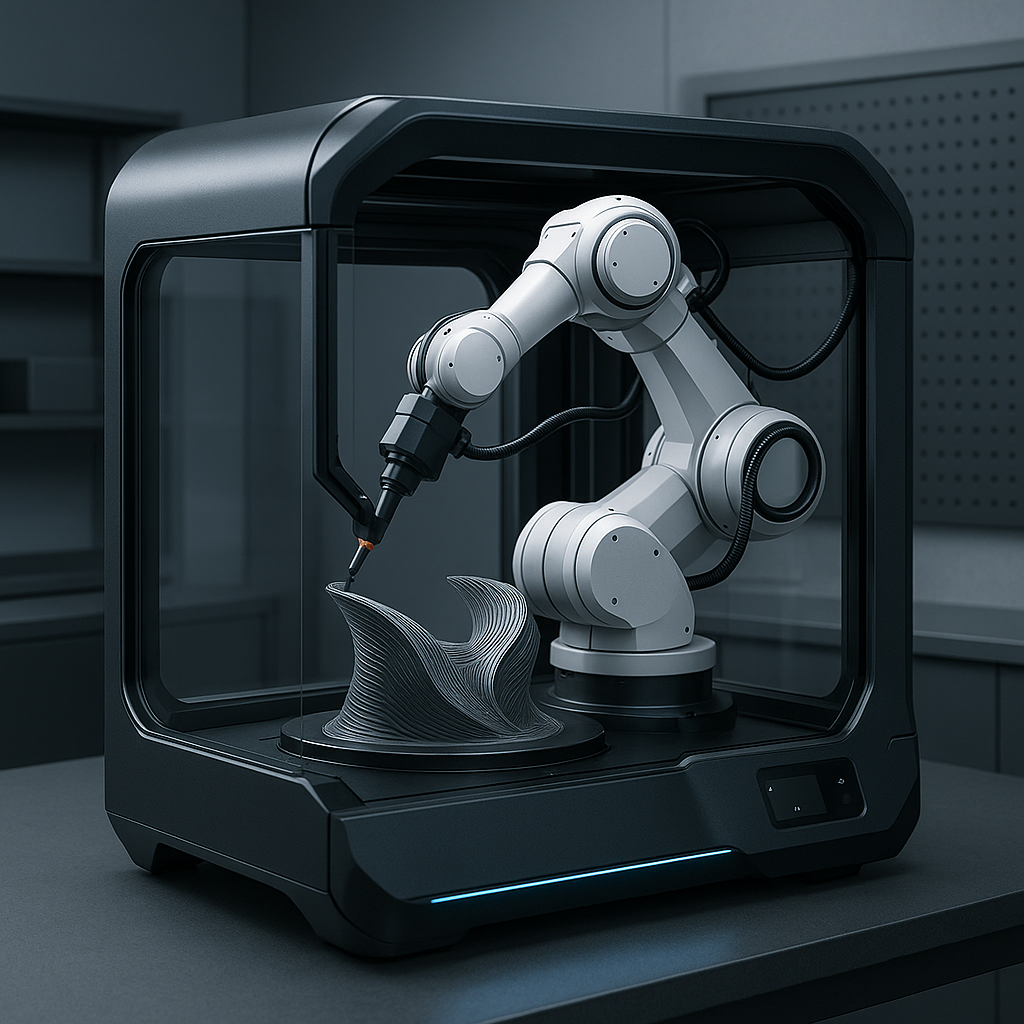

Generative Machine Company has recently introduced a breakthrough in desktop 3D printing by making 5-axis 3D printing technology accessible in a compact, desktop form factor, as reported by 3DPrint.com. This development marks a significant step forward from traditional planar 3D printing by enabling multi-axis movement during the extrusion process, which until now has largely been confined to industrial-scale machines due to mechanical complexity and cost.

Why It Matters

The introduction of 5-axis capabilities in a desktop 3D printer opens new possibilities for hobbyists, designers, and engineers who require complex geometries with minimal support structures. By moving beyond the conventional layer-by-layer planar approach, this technology allows for continuous, non-planar printing paths that better align with the part’s geometry, improving surface finish, mechanical properties, and reducing post-processing time. This democratization of advanced multi-axis printing could accelerate innovation in fields such as custom prosthetics, aerospace components, and artistic fabrication.

Technical Context

Traditional desktop 3D printers operate primarily on three linear axes (X, Y, Z), depositing material in flat, horizontal layers. In contrast, 5-axis 3D printing introduces two additional rotational degrees of freedom, allowing the print head or the build platform to tilt and rotate during printing. This capability enables the nozzle to maintain an optimal angle relative to the surface, facilitating non-planar extrusion paths. The advantages include enhanced layer adhesion, the ability to print overhangs and complex curves without extensive support, and improved anisotropic mechanical properties.

Industrial 5-axis systems have existed but are typically large, expensive, and complex, limiting their accessibility. Generative Machine Company’s innovation lies in miniaturizing and simplifying the mechanics and control systems to fit within a desktop footprint, though specific details on the machine’s architecture, software integration, and material compatibility remain undisclosed at this time.

Near-Term Prediction Model

Given the early stage of commercial availability, 5-axis desktop 3D printing is currently in the pilot phase. Over the next 12 to 24 months, we anticipate gradual adoption among advanced hobbyists and small-scale professional users who can leverage its unique capabilities for prototyping and small-batch production. As firmware and slicing software evolve to better support non-planar toolpaths, and as material formulations adapt to multi-axis extrusion dynamics, the technology’s usability and reliability will improve.

Cost and complexity remain barriers to mass adoption. However, if Generative Machine Company and competitors can streamline user experience and demonstrate clear advantages over conventional printers, broader uptake in design studios, educational institutions, and niche manufacturing sectors is plausible within a 3-year horizon.

What to Watch

- Software development for non-planar slicing and multi-axis path planning, which is critical to unlocking the full potential of 5-axis printing.

- Material innovations tailored for multi-axis extrusion, including composites and flexible filaments that can benefit from angled deposition.

- Emerging use cases demonstrating clear advantages in mechanical performance, surface finish, or design freedom compared to planar printing.

- Competitive responses from established 3D printer manufacturers and the entrance of additional startups in the multi-axis desktop printing space.

- User community feedback and case studies that highlight practical challenges and benefits, shaping iterative improvements.

While the Generative Machine Company’s 5-axis desktop 3D printer is a promising advancement, further transparency on machine specifications, pricing, and real-world performance will be essential to fully assess its impact on the additive manufacturing landscape.