What Happened

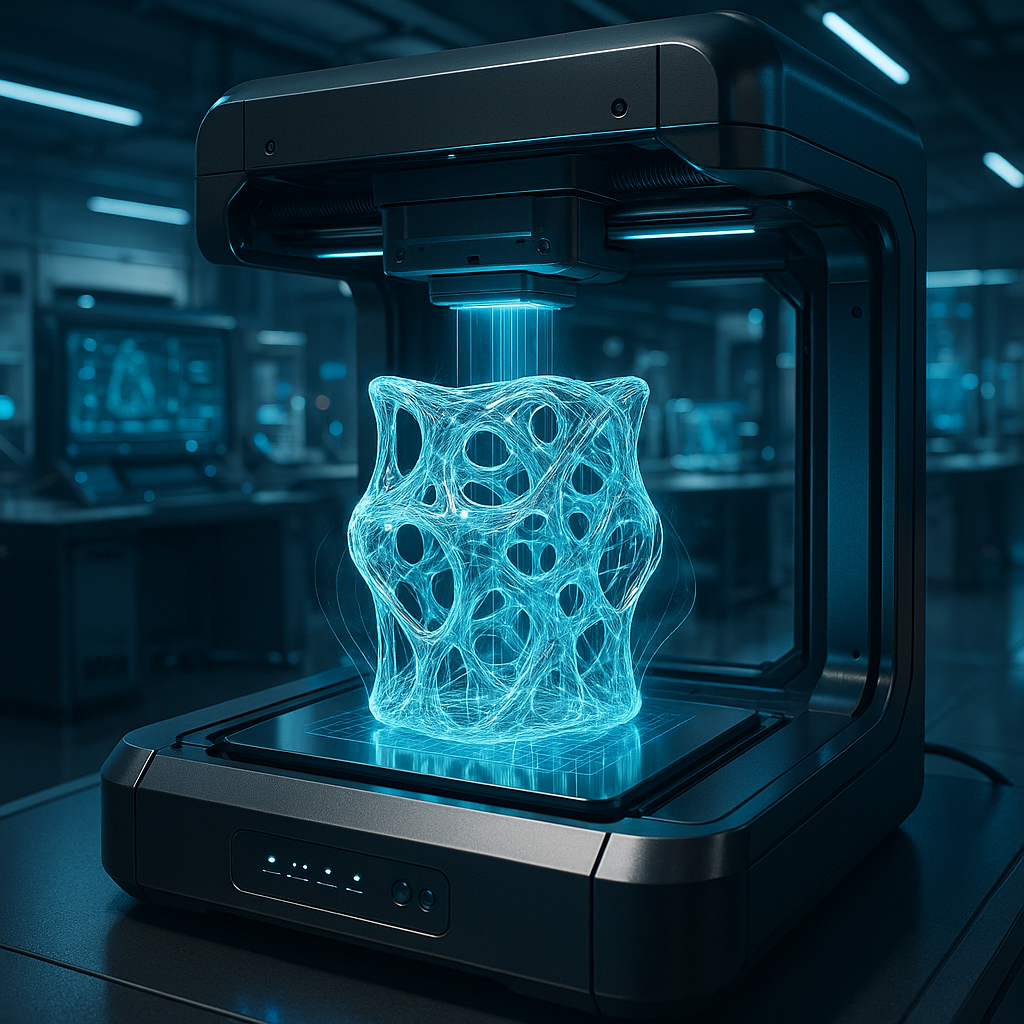

Recently, a breakthrough in volumetric 3D printing was reported by 3D Printing Industry. The innovation involves sub-second volumetric 3D printing using holographic light synthesis, enabling the creation of complex 3D objects within fractions of a second. This technology diverges from traditional layer-by-layer additive manufacturing by curing entire volumes simultaneously through holographically patterned light.

Why It Matters

This development is significant because it addresses one of the longstanding limitations of 3D printing: speed. Conventional 3D printing methods often require minutes to hours to complete an object, limiting their use in rapid prototyping and high-throughput manufacturing. By reducing print times to under a second, volumetric 3D printing with holographic light synthesis could dramatically accelerate product development cycles, enable on-demand manufacturing, and open new applications where speed and complexity are critical.

Moreover, volumetric printing inherently minimizes mechanical stresses and layer artifacts common in traditional methods, potentially improving mechanical properties and surface finish quality. This could expand the range of materials and industries that benefit from 3D printing, including medical devices, aerospace components, and customized consumer products.

Technical Context

Volumetric 3D printing differs fundamentally from typical additive manufacturing techniques like stereolithography (SLA) or fused deposition modeling (FDM). Instead of building an object layer-by-layer, volumetric printing cures a photosensitive resin in a single exposure by projecting a three-dimensional light pattern that solidifies the entire volume simultaneously.

The recent advancement leverages holographic light synthesis to create these complex 3D light patterns. Holography uses interference patterns of light waves to shape light in three dimensions precisely. By synthesizing holographic projections rapidly and accurately, the system can cure intricate geometries within sub-second timescales.

While volumetric printing concepts have existed for several years, prior implementations were constrained by resolution, print size, or speed. This new approach appears to overcome some of those limitations, although detailed technical specifications such as achievable resolution, build volume, material compatibility, and energy consumption remain undisclosed.

Near-term Prediction Model

Given the current state of research and development, this sub-second volumetric 3D printing technology is likely in the R&D to Pilot stages. It will probably take approximately 12 to 24 months before commercial-grade systems become available for niche applications. Early adopters may include research institutions and industries requiring ultra-fast prototyping or specialized components.

The impact score for this technology is high, around 85/100, due to its potential to disrupt existing additive manufacturing workflows significantly. Confidence in its eventual commercialization is moderate (70/100) since challenges remain in scaling, material diversity, and cost-effectiveness.

Key risks include the complexity of holographic system integration, limitations in printable material types, and potential high capital costs that may slow adoption. Additionally, regulatory and certification pathways for critical applications like medical devices will require thorough validation.

What to Watch

- Announcements from startups or established 3D printing companies adopting holographic volumetric printing techniques.

- Research publications detailing resolution, material compatibility, and mechanical properties of printed parts.

- Development of new photosensitive resins optimized for rapid volumetric curing.

- Demonstrations of scaled-up build volumes and complex geometries in real-world applications.

- Cost analysis and comparisons with existing rapid prototyping technologies.

In conclusion, sub-second volumetric 3D printing using holographic light synthesis represents a promising frontier in additive manufacturing. While still emerging, its ability to print entire volumes instantaneously could redefine speed and quality standards in 3D printing, warranting close attention from industry stakeholders and researchers alike.