What Happened

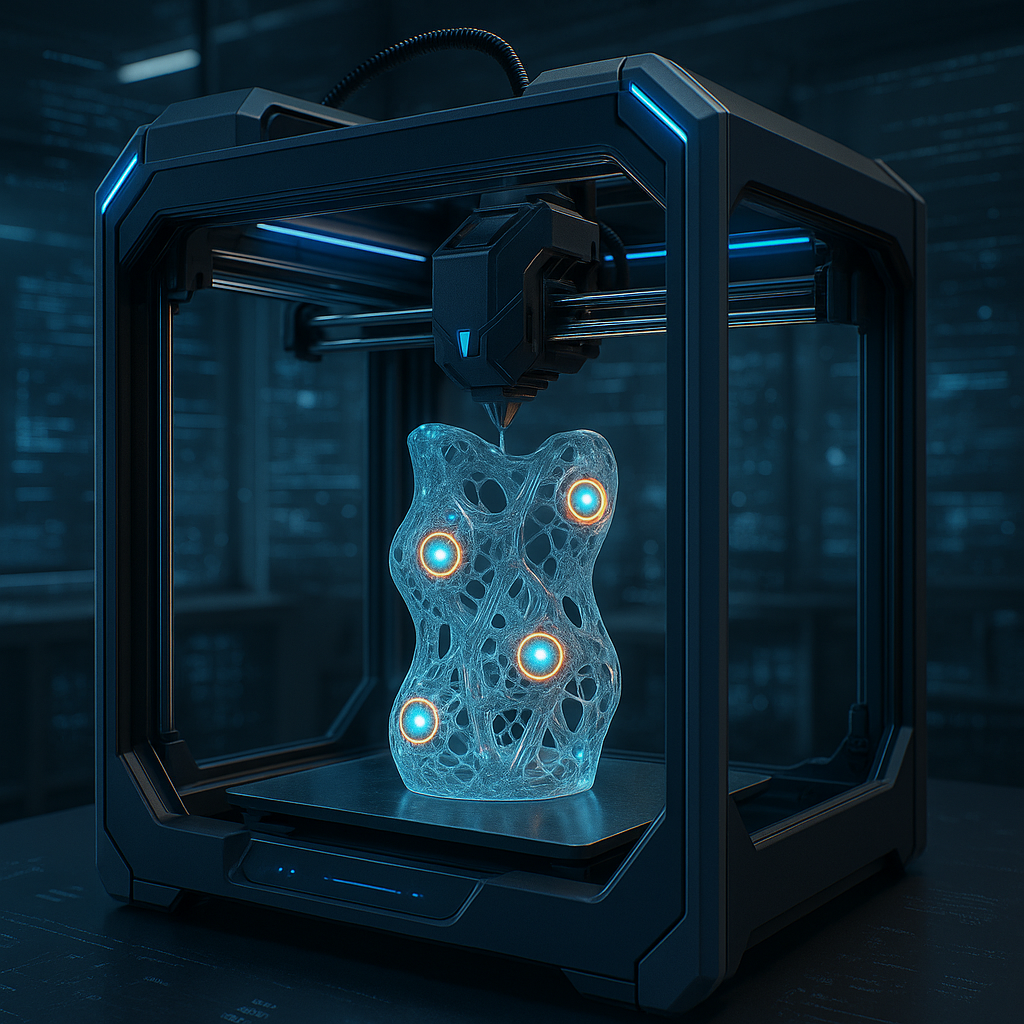

Researchers at Berkeley Engineering have recently demonstrated a pioneering 3D printing technique designed to fabricate quantum sensors with embedded sensing capabilities. This development, detailed in their Berkeley Engineering news release, marks a significant step in integrating quantum sensing elements directly within 3D printed structures, enabling new classes of smart and bio-embedded materials.

Why It Matters

Quantum sensors are renowned for their extreme sensitivity and precision in measuring physical quantities such as magnetic fields, temperature, and pressure. Traditionally, manufacturing these sensors involves complex, multi-step processes that limit scalability and their integration into complex geometries. The Berkeley team’s 3D printing approach opens the door to embedding quantum sensors directly into 3D printed objects, potentially revolutionizing applications in healthcare, environmental monitoring, and wearable technology. This integration could lead to devices that are more compact, robust, and capable of real-time sensing in environments previously inaccessible to conventional sensors.

Technical Context

The new technique leverages advanced additive manufacturing methods to incorporate quantum sensing materials—likely diamond nitrogen-vacancy centers or similar quantum defects—within printed substrates. Although the exact materials and printing parameters have not been fully disclosed, the approach appears to combine precise material deposition with controlled curing or sintering processes to preserve the quantum properties during fabrication. This contrasts with traditional sensor manufacturing that typically involves assembling pre-fabricated sensing elements into devices. Embedding sensors during printing reduces assembly steps and allows for unprecedented design freedom, enabling sensors to conform to complex shapes and integrate with biological tissues or flexible electronics.

While details on the resolution, sensitivity retention, and scalability of the process remain to be published, this technique aligns with broader trends in smart material development where sensing and actuation capabilities are seamlessly integrated at the material level. It also hints at potential compatibility with bio-embedding, where sensors could be incorporated into implants or wearable devices for continuous health monitoring.

Near-term Prediction Model

Given the current stage of this research, the technology is in the R&D phase, with a time horizon of approximately 24 to 36 months before pilot demonstrations in applied settings. Early prototypes may soon emerge in laboratory environments, validating sensor performance and durability. Commercial adoption will depend on overcoming challenges such as ensuring quantum coherence post-printing, material biocompatibility, and manufacturing scalability.

The impact score for this technology is estimated at 75, reflecting its potential to disrupt sensor manufacturing and enable new applications, balanced against the technical hurdles ahead. Confidence is moderate at 65 due to limited public data and the inherent complexity of quantum materials integration.

What to Watch

- Publication of detailed technical papers outlining the materials used, printing parameters, and sensor performance metrics.

- Demonstrations of embedded quantum sensors in real-world applications such as wearable health monitors, environmental sensors, or robotics.

- Advancements in compatible bio-embedding techniques that integrate these sensors with living tissues without compromising functionality.

- Collaborations or partnerships between Berkeley Engineering and industry players in 3D printing, quantum technology, and biomedical devices.

- Regulatory and safety assessments related to embedding quantum sensors in consumer or medical products.

While many specifics remain unknown, this breakthrough exemplifies the frontier of smart and bio-embedded materials, positioning 3D printing as a transformative tool for next-generation sensor technologies.