What Happened

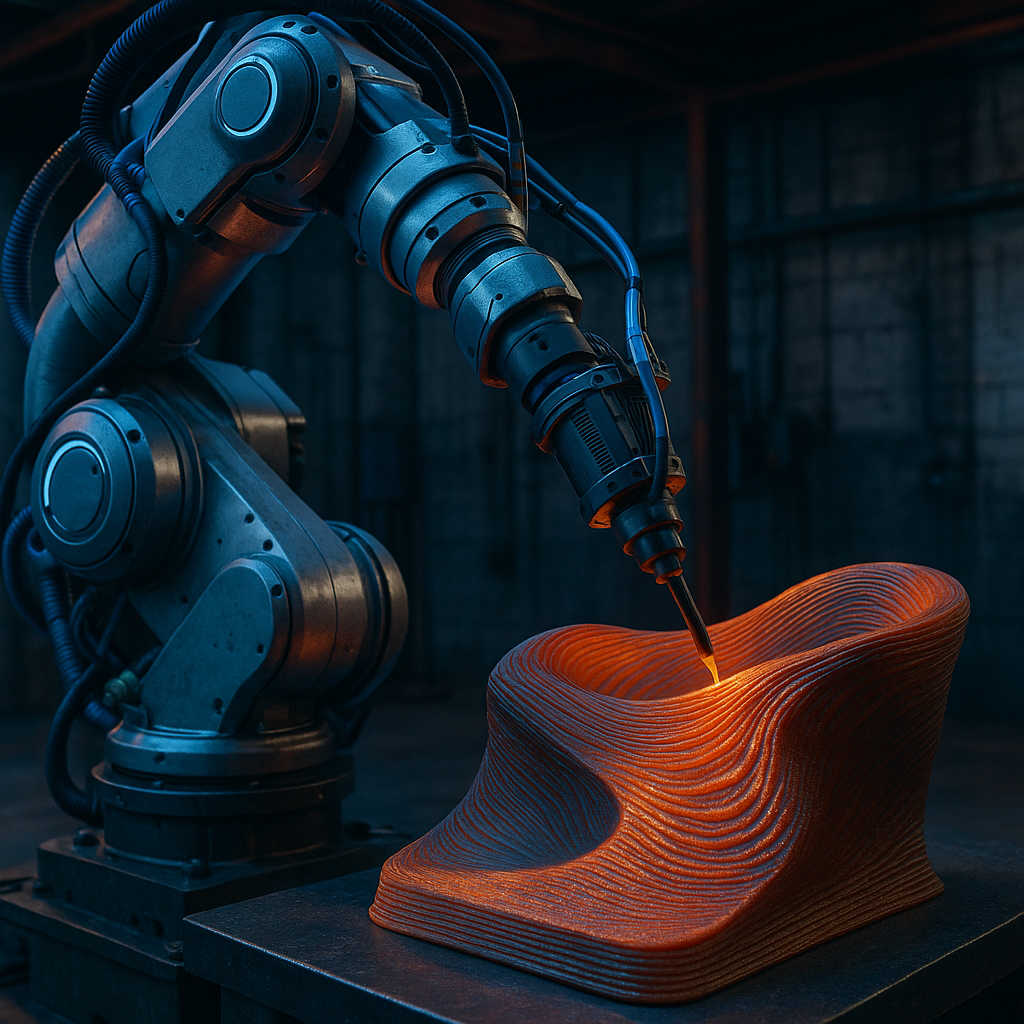

On February 14, 2026, 3DPrint.com published a news briefing highlighting several advancements in additive manufacturing, including applications of robotic arm 3D printing in maritime construction and prosthetics. While the briefing covered a range of topics, the integration of robotic arms for non-planar and multi-axis 3D printing stood out as an emerging frontier with significant implications for design complexity and manufacturing efficiency.

Why It Matters

Traditional 3D printing typically relies on planar, layer-by-layer deposition along fixed X, Y, and Z axes. Robotic arm 3D printing breaks this mold by enabling non-planar and multi-axis motion, allowing the print head to move along complex trajectories and angles. This capability enhances geometric freedom, reduces the need for support structures, and improves surface finish by printing along curved surfaces or varying orientations.

These advantages are crucial in sectors like maritime construction, where large-scale, complex geometries are common, and prosthetics, which demand customized, ergonomic shapes. The ability to print directly onto curved or irregular surfaces with robotic arms reduces post-processing and assembly steps, lowering costs and accelerating production timelines. This innovation also opens new possibilities for lightweight, functionally graded, and multi-material components.

Technical Context

Robotic arm 3D printing leverages multi-axis industrial robots equipped with extrusion or directed energy deposition tools. Unlike gantry-based printers with fixed orthogonal axes, robotic arms offer 6 degrees of freedom, enabling the print nozzle to orient in any direction. This flexibility supports non-planar layer deposition, where layers are not flat but follow the part’s geometry, reducing the stair-stepping effect and enhancing mechanical properties by aligning material deposition with stress paths.

Challenges remain in path planning, collision avoidance, and real-time process control due to the increased complexity of multi-axis trajectories. Software development for slicing and toolpath generation must accommodate these degrees of freedom, integrating kinematics and dynamics of robotic arms. Additionally, maintaining consistent extrusion and adhesion on varied orientations requires precise synchronization between motion and material flow.

Materials used in robotic arm 3D printing span thermoplastics, composites, and metals, with ongoing research into curing methods and interlayer bonding to optimize strength and durability. Integration with sensors and feedback loops is critical to monitor print quality and adapt parameters dynamically.

Near-Term Prediction Model

Robotic arm 3D printing is currently transitioning from pilot to early commercial stages, particularly in niche applications such as large-scale maritime parts and custom prosthetics. Over the next 12 to 24 months, we expect broader adoption driven by improvements in software ecosystems and hardware reliability. The impact score is estimated at 75 out of 100, reflecting significant potential to disrupt traditional manufacturing workflows but tempered by integration challenges and cost.

Key risks include complex system calibration, high capital investment, and the need for skilled operators. However, ongoing research and collaboration between robotics and additive manufacturing specialists are rapidly addressing these barriers. As standards and best practices emerge, the technology will become more accessible to mid-sized manufacturers.

What to Watch

- Development of advanced path planning algorithms tailored for multi-axis deposition and collision avoidance.

- Integration of real-time monitoring sensors enabling closed-loop control for consistent print quality.

- Material innovations that improve adhesion and mechanical properties in non-planar printed layers.

- Case studies demonstrating cost and time savings in maritime construction and prosthetics manufacturing.

- Collaborations between robotic arm manufacturers and 3D printing software companies to streamline workflows.

- Regulatory and certification progress for safety and performance of parts produced via multi-axis robotic 3D printing.

While many details about specific projects and technical implementations remain undisclosed in the source briefing, the trajectory for robotic arm 3D printing as a transformative non-planar and multi-axis additive manufacturing technology is clear. Industry stakeholders should monitor advancements closely to leverage its benefits and prepare for integration into their production ecosystems.