What Happened

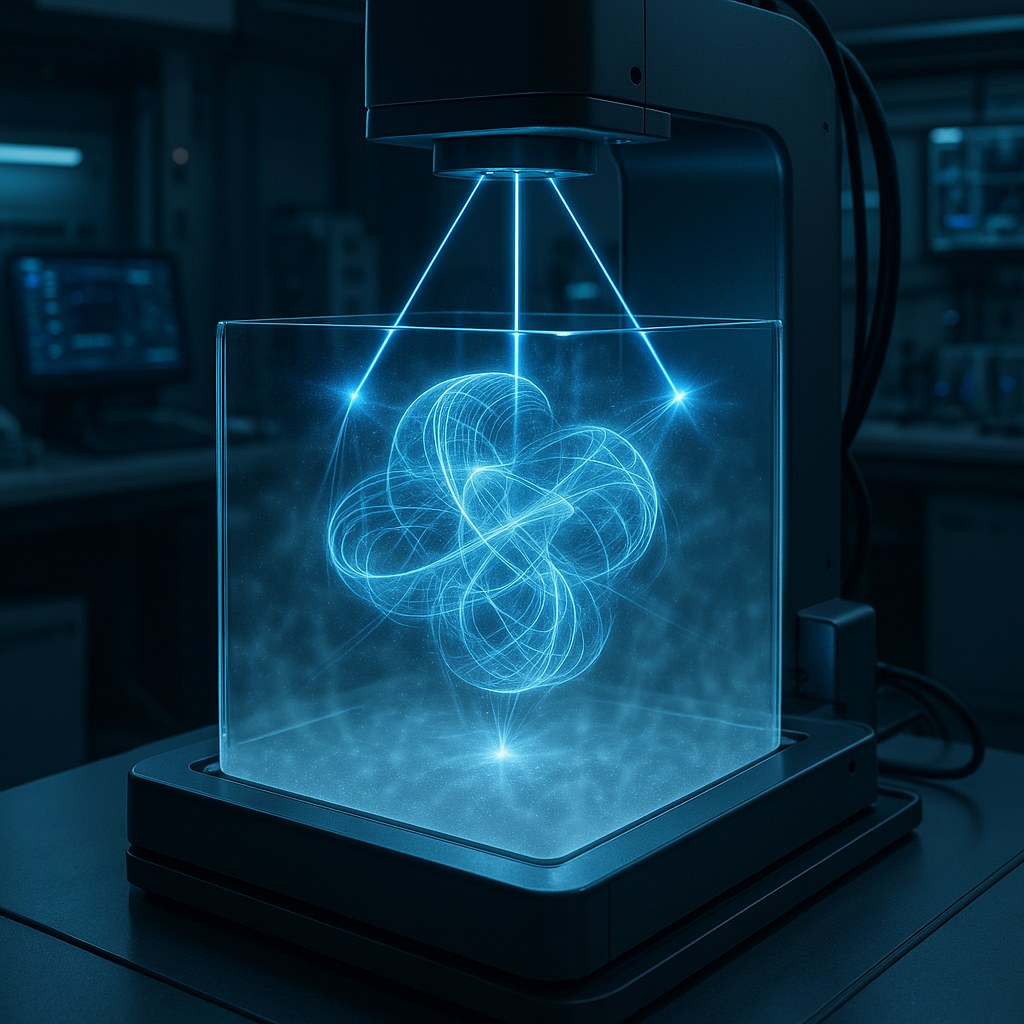

Recent research highlighted by Wiley focuses on controlling light propagation within scattering materials to enhance volumetric additive manufacturing processes. This work addresses a fundamental challenge in tomographic or volumetric 3D printing — how to precisely deliver and shape light inside materials that scatter photons, which traditionally limits resolution and print fidelity.

Why It Matters

Volumetric printing, particularly tomographic printing, is an emerging 3D printing technique where a three-dimensional object is formed simultaneously within a volume by projecting light patterns from multiple angles. Unlike traditional layer-by-layer approaches, volumetric printing promises ultra-fast fabrication times and complex geometries without supports. However, many resins or photopolymers used in these processes scatter light, causing blurring and inaccuracies. Overcoming this optical scattering barrier is critical to unlocking volumetric printing’s full potential for industrial and biomedical applications.

Technical Context

Tomographic volumetric printing relies on computational algorithms to calculate the light dose distribution required to solidify a target 3D shape inside a photosensitive resin. The resin’s optical properties, especially scattering and absorption, distort these projections, degrading print quality. The research highlighted by Wiley explores advanced methods to control light within scattering media, including adaptive optics, wavefront shaping, and feedback mechanisms to correct distortions dynamically.

Controlling light in scattering materials involves manipulating the phase and amplitude of incident light waves to compensate for scattering effects, effectively focusing or shaping light deep inside the resin volume. This requires sophisticated hardware such as spatial light modulators and real-time sensing combined with complex computational models. The goal is to achieve accurate dose delivery that matches the intended 3D pattern, enabling high-resolution volumetric prints in otherwise challenging materials.

Near-term Prediction Model

Currently, this technology remains primarily in the research and development phase, with pilot demonstrations showing promise but not yet widespread commercial deployment. Over the next 12 to 24 months, we can expect incremental improvements in system integration, computational algorithms, and hardware miniaturization, enabling volumetric printers that handle scattering resins more reliably.

Early adopters will likely be specialized sectors requiring rapid prototyping of complex geometries or biomedical applications such as tissue scaffolds where volumetric printing’s speed and geometry freedom are invaluable. However, broader industrial adoption depends on reducing system complexity and cost while improving robustness.

What to Watch

- Advances in adaptive optics hardware tailored for volumetric printing setups.

- Development of real-time feedback and sensing technologies to dynamically correct light scattering during printing.

- New photopolymer formulations with tunable scattering properties optimized for tomographic printing.

- Integration of machine learning approaches to predict and compensate for complex scattering patterns.

- Commercial pilot projects demonstrating volumetric printing of functional parts in scattering materials.

While the Wiley article sheds light on controlling scattering, details on specific hardware implementations and scalability remain limited, underscoring the need for continued multidisciplinary research.