In a significant leap for aerospace manufacturing, Airbus is pioneering titanium 3D printing through innovative use of robotic arm 3D printing technology. This approach leverages multi-axis, non-planar additive manufacturing to produce complex aircraft components with enhanced structural integrity and reduced waste.

What Happened

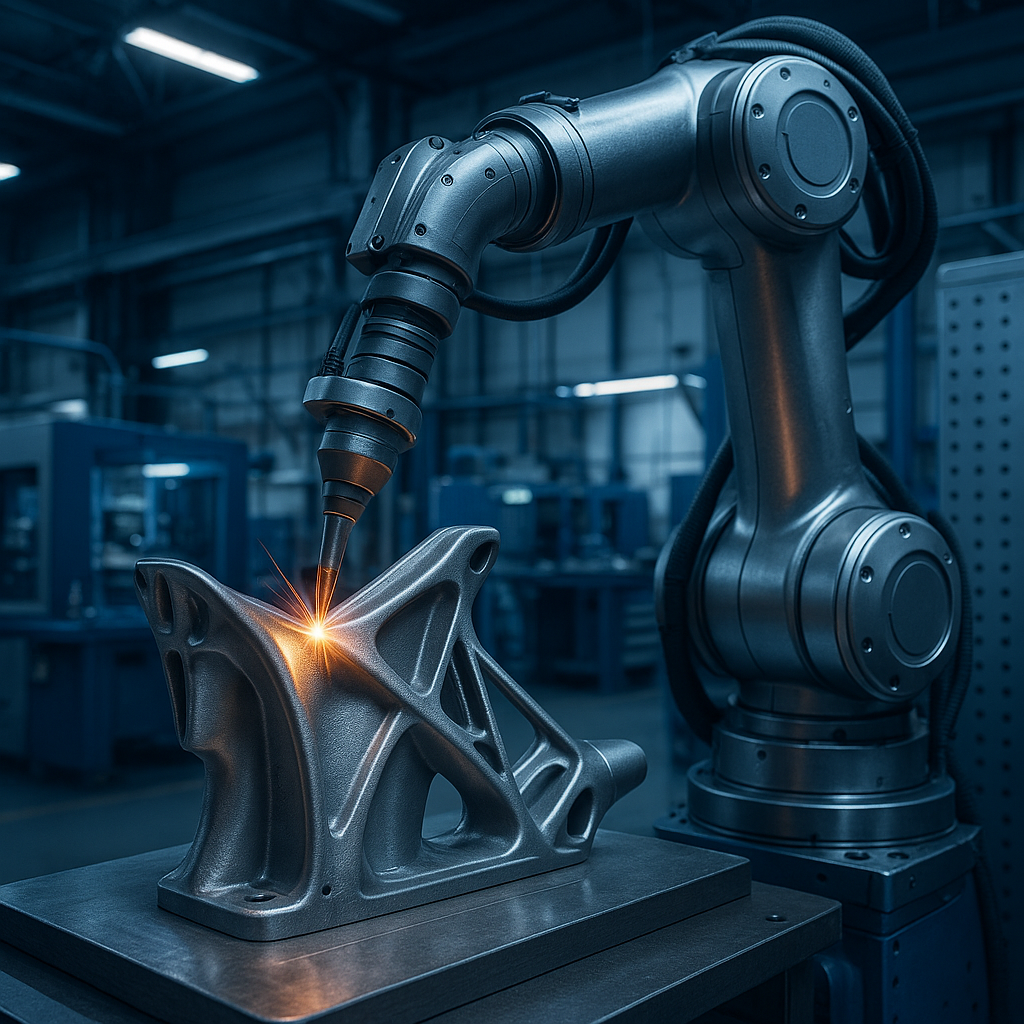

Airbus has integrated robotic arm 3D printing systems into its titanium parts production workflow, marking a departure from traditional planar, layer-by-layer metal additive manufacturing. Utilizing multi-axis robotic arms, the company can print on curved surfaces and build parts in orientations that optimize mechanical properties and reduce the need for support structures. This development was reported recently by AirGuide Business, highlighting Airbus’s commitment to pushing the boundaries of aerospace manufacturing.

Why It Matters

This advancement is critical because titanium alloys are notoriously challenging to machine and manufacture due to their strength and thermal properties. Traditional subtractive methods are wasteful and time-consuming, while conventional 3D printing often requires extensive post-processing. By employing robotic arms capable of multi-axis movement, Airbus can deposit titanium material more precisely and efficiently, enabling the production of parts with complex geometries that were previously impossible or prohibitively expensive to fabricate.

Furthermore, the ability to print non-planar layers reduces residual stresses and enhances the microstructure of the metal, potentially leading to stronger, lighter, and more reliable aircraft components. This could translate to improved fuel efficiency and lower maintenance costs in the aerospace sector.

Technical Context

Robotic arm 3D printing is a form of multi-axis additive manufacturing that moves beyond the traditional Cartesian XYZ gantry systems. Instead of building parts layer by layer on a flat plane, robotic arms can orient the print head in multiple degrees of freedom, enabling deposition on curved or angled surfaces. This non-planar printing approach allows for continuous material deposition along complex paths, reducing layer interfaces and improving mechanical continuity.

In the context of titanium, which requires high-temperature processing and precise control to avoid defects, robotic arms equipped with directed energy deposition (DED) or laser powder bed fusion (LPBF) heads provide the flexibility needed for complex builds. While the exact technology Airbus uses is not fully disclosed, it likely involves advanced process monitoring and adaptive control to maintain quality during multi-axis printing.

This approach also facilitates the integration of repair and refurbishment processes, where robotic arms can add material selectively to existing parts, extending their lifecycle.

Near-term Prediction Model

Given the current state of technology and Airbus’s industrial resources, this multi-axis titanium 3D printing is transitioning from pilot projects to early commercial deployment within the next 12 to 24 months. The maturity stage can be classified as Pilot moving towards Commercial, with ongoing validation and certification efforts underway.

The impact score is estimated at 75 out of 100, reflecting significant potential to disrupt aerospace manufacturing but tempered by challenges such as certification, repeatability, and scale-up. Confidence in this prediction is moderate to high (around 70), based on Airbus’s track record and industry trends.

What to Watch

- Regulatory certification milestones for 3D printed titanium parts produced via robotic arm multi-axis printing.

- Advances in in-situ process monitoring and adaptive control systems that ensure consistent quality during complex builds.

- Expansion of robotic arm 3D printing beyond aerospace into other high-value sectors such as automotive and medical implants.

- Development of new titanium alloys optimized for multi-axis additive manufacturing.

- Collaborations or partnerships between Airbus and 3D printing technology providers focusing on robotic arm systems.

While many details about Airbus’s exact robotic arm 3D printing setup remain proprietary, the move signals a broader industry shift towards non-planar, multi-axis additive manufacturing as a means to unlock new design freedoms and manufacturing efficiencies.