What Happened

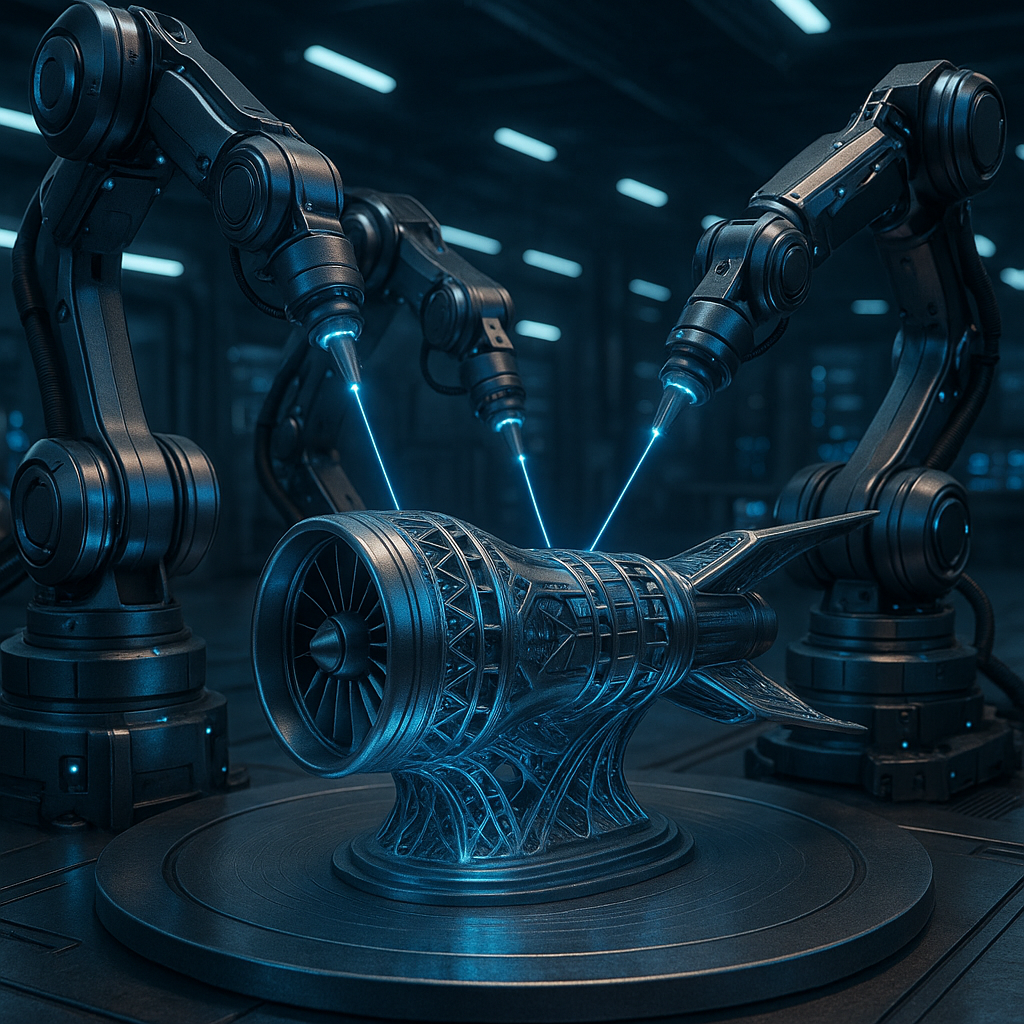

Beehive, an aerospace engineering company, is rapidly advancing its 3D-printed Frenzy engine toward scheduled flight tests in 2026, as reported by Aerospace Global News. The Frenzy engine leverages advanced 3D printing techniques, notably swarm and collaborative printing methods, to accelerate production and optimize design complexity. This milestone positions Beehive at the forefront of integrating swarm 3D printing in aerospace propulsion systems.

Why It Matters

The aerospace sector has long sought to reduce manufacturing time and costs while enhancing component performance. Swarm 3D printing—where multiple printers or printing elements operate collaboratively—promises to revolutionize this by enabling simultaneous fabrication of complex parts at scale. Beehive’s Frenzy engine project demonstrates practical application of these principles, potentially shortening development cycles and improving engine efficiency through design freedom afforded by additive manufacturing.

Successful flight tests in 2026 would validate swarm 3D printing as a credible manufacturing approach for critical aerospace components, potentially catalyzing wider adoption across the industry. This could lead to more resilient supply chains, greater customization, and rapid iteration capabilities.

Technical Context

Swarm 3D printing involves orchestrating multiple print heads or machines to work in tandem, either on a single part or across multiple components, to increase throughput and enable complex geometries that single printers cannot easily achieve. In Beehive’s case, the Frenzy engine benefits from distributed printing of intricate parts that are subsequently assembled or integrated, reducing lead times and minimizing human error.

While specific technical details of the Frenzy engine’s printing process remain undisclosed, it likely incorporates metal additive manufacturing techniques such as laser powder bed fusion or directed energy deposition, optimized for aerospace-grade materials. Collaborative printing here implies synchronized operation of multiple printers or modular print units, possibly with real-time feedback control to ensure dimensional accuracy and structural integrity.

Challenges in swarm printing include maintaining consistent quality across units, managing the interface between printed segments, and ensuring the mechanical reliability of assembled parts under extreme operational conditions. Beehive’s progress suggests these hurdles are being addressed through advanced process control and design-for-additive manufacturing strategies.

Near-Term Prediction Model

Given the announced timeline targeting flight tests in 2026, Beehive’s Frenzy engine project is currently in the pilot stage of maturity. Over the next 12 to 18 months, expect continued refinement of printing workflows, integration of swarm printing systems, and extensive ground testing to validate performance and reliability.

If flight tests succeed, the technology could transition to early commercial adoption by late 2026 or 2027, initially for niche aerospace applications requiring rapid prototyping or low-volume production of complex parts. Broader industry uptake will depend on demonstrated cost-effectiveness, certification outcomes, and scalability of swarm 3D printing systems.

What to Watch

- Results and data from the 2026 flight tests, including engine performance and durability metrics.

- Technical disclosures or publications from Beehive detailing their swarm 3D printing architecture and process innovations.

- Regulatory and certification progress for 3D-printed aerospace propulsion components produced via swarm methods.

- Emerging partnerships or collaborations between Beehive and aerospace OEMs or additive manufacturing technology providers.

- Advancements in real-time monitoring and quality control systems that enable reliable swarm printing at scale.

While some technical specifics and the exact nature of the swarm printing system remain unknown, Beehive’s Frenzy engine initiative represents a significant step toward operationalizing collaborative 3D printing in aerospace. Its progress will be a bellwether for the sector’s readiness to embrace swarm manufacturing as a mainstream production paradigm.