What Happened

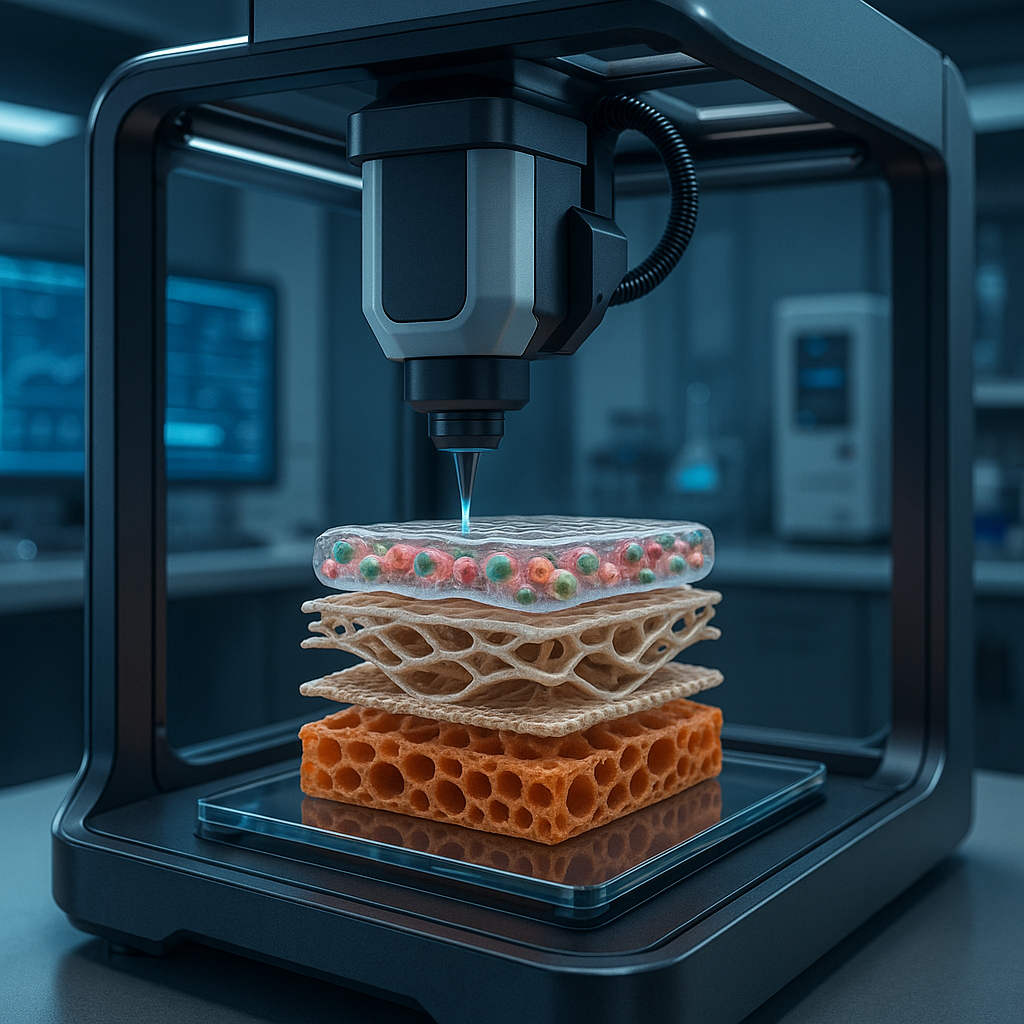

Recent research highlighted in Science Partner Journals unveils advances in bioinspired additive manufacturing techniques for creating hierarchical materials. These materials mimic complex biological structures and functions, enabling new possibilities for bio-embedded 3D printing technologies. The study synthesizes current methods and showcases how additive manufacturing can replicate nature’s multi-scale architectures, from nanoscale to macroscale, to achieve enhanced mechanical, optical, and functional properties.

Why It Matters

The integration of bio-embedded materials into 3D printing represents a paradigm shift in manufacturing smart materials that are not only structurally sophisticated but also functionally adaptive. Traditional manufacturing struggles to replicate the intricate hierarchical architectures found in nature, which are critical for properties like strength, flexibility, self-healing, and responsiveness. By leveraging bioinspired additive manufacturing, industries can produce materials with unprecedented performance tailored for biomedical devices, soft robotics, wearable sensors, and environmental applications. This approach also opens pathways to embedding living cells or biomolecules within printed structures, enabling next-generation biohybrid systems.

Technical Context

Hierarchical materials are characterized by structural organization across multiple length scales, often resulting in emergent properties unattainable by homogeneous materials. Nature exemplifies this in bone, nacre, and plant fibers, where nano- to macroscale features combine to provide durability and adaptability. The research delves into advanced additive manufacturing techniques such as multi-material printing, micro-extrusion, and light-based polymerization, integrated with biofabrication strategies to replicate these architectures.

Challenges include controlling material composition and spatial distribution at micro- and nanoscale resolutions, ensuring biocompatibility when embedding living components, and maintaining functionality during and after the printing process. The study discusses current progress in combining synthetic polymers, hydrogels, ceramics, and living cells in layered constructs that emulate natural gradients and interfaces.

Near-Term Prediction Model

In the next 12 to 24 months, expect pilot-scale demonstrations of bio-embedded hierarchical materials in specialized applications such as tissue scaffolds with enhanced mechanical mimicry and responsive soft robotic components. Commercial adoption will initially focus on niche biomedical devices and research tools, as material standardization and regulatory pathways mature. Continued R&D will be crucial to improve printing resolution, biointegration, and scalability.

What to Watch

- Breakthroughs in multi-material 3D printing platforms capable of nanoscale precision and bio-compatibility.

- Development of standardized bio-inks and composite materials optimized for hierarchical structuring.

- Regulatory approvals and clinical trials involving bio-embedded printed implants or sensors.

- Collaborations between materials scientists, biologists, and engineers to push functional integration.

- Emergence of biohybrid devices combining living cells with synthetic frameworks for adaptive behavior.

While the foundational science is advancing rapidly, many practical challenges remain, including long-term stability of bio-embedded materials and cost-effective manufacturing. Nevertheless, the trajectory indicates a transformative impact on how we design and fabricate smart, functional materials inspired by nature’s own engineering.