What Happened

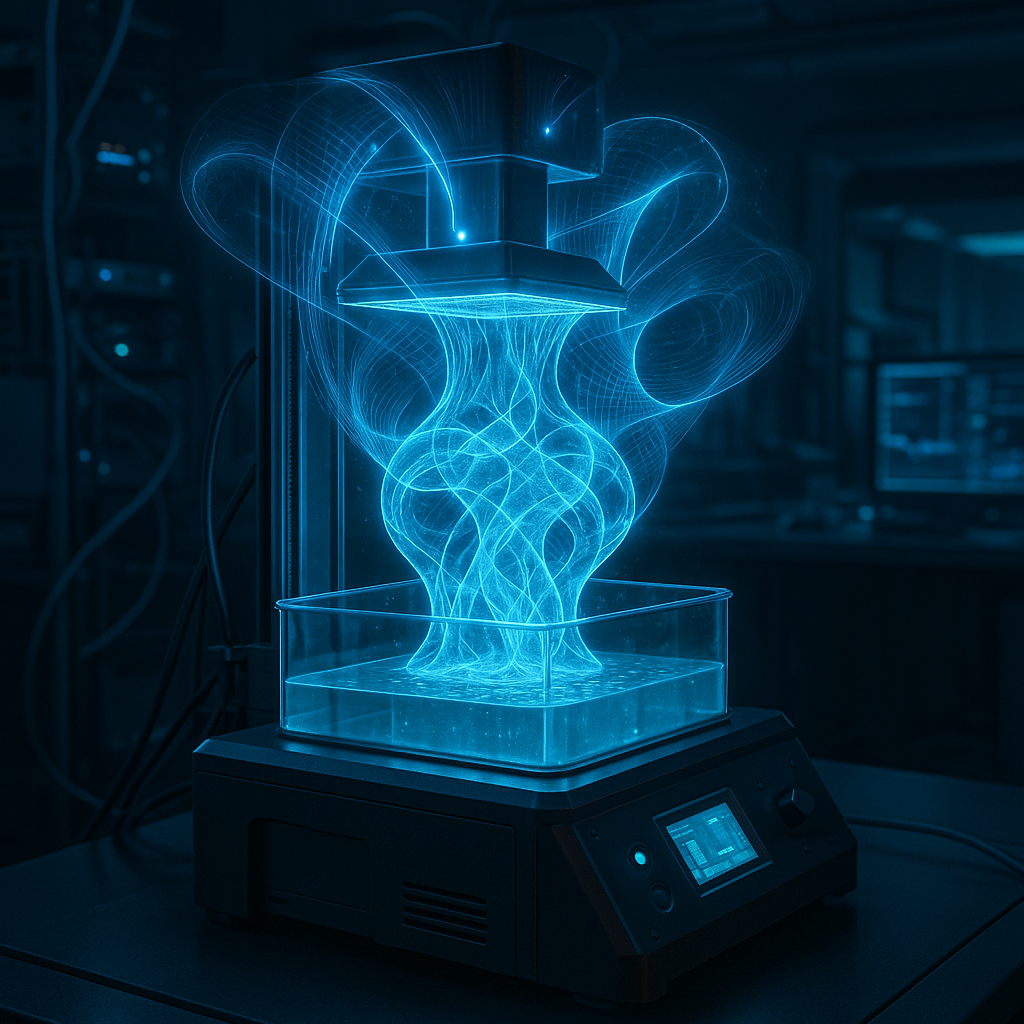

A recent publication in Nature unveiled a pioneering volumetric 3D printing technique that achieves sub-second fabrication speeds by synthesizing holographic light fields. This method advances beyond traditional layer-by-layer additive manufacturing by projecting complex light patterns that solidify photosensitive resin volumetrically and instantaneously, enabling the creation of entire 3D objects within fractions of a second.

Why It Matters

The implications of this breakthrough are profound for industries relying on rapid prototyping and manufacturing. Conventional 3D printing methods, including stereolithography and fused deposition modeling, are limited by sequential layering processes, which can take hours or days for complex parts. The sub-second volumetric approach promises drastic reductions in production times, opening pathways for on-demand manufacturing, customization, and even applications in biomedical fields where speed and precision are critical.

Moreover, volumetric printing eliminates common defects associated with layering, such as anisotropic mechanical properties and visible layer lines, potentially improving the structural integrity and surface finish of printed parts. The use of holographic light fields to sculpt resin volumes volumetrically is a novel approach that could redefine speed and quality benchmarks in 3D printing.

Technical Context

Volumetric 3D printing diverges from traditional additive manufacturing by curing an entire volume of resin simultaneously rather than layer-by-layer. Previous volumetric methods often relied on computed tomography (CT)-inspired light projections rotating around the resin volume, which, while faster than layering, still required several seconds to minutes.

The Nature article introduces a synthesis of holographic light fields, leveraging advanced spatial light modulators and computational holography to project complex 3D light patterns that selectively polymerize resin in a single exposure lasting less than a second. This requires precise control of light intensity and phase to ensure accurate voxel-wise curing throughout the volume, overcoming challenges like light scattering and resin oxygen inhibition.

While the article does not fully detail the resin chemistry or the limits of achievable resolution and part size, it marks a significant leap in the speed and complexity of volumetric printing. The integration of holographic techniques with photopolymerization chemistry represents a frontier intersection of optics, materials science, and additive manufacturing.

Near-Term Prediction Model

Given the current state of research, this holographic volumetric printing technique is in an advanced research and early pilot phase. Commercial adoption will depend on scaling the technology to larger build volumes, developing compatible resins with suitable mechanical properties, and integrating the hardware into robust, user-friendly systems.

Within the next 18 to 36 months, we can anticipate pilot deployments in specialized applications such as microfluidics, biomedical implants, and rapid prototyping for aerospace components where speed and precision yield competitive advantages. Broader commercial use in consumer or industrial manufacturing may take longer, contingent on overcoming material limitations and cost reduction.

What to Watch

- Development of new photopolymer resins optimized for holographic volumetric curing that balance speed, resolution, and mechanical performance.

- Advancements in spatial light modulator technology and computational holography algorithms to increase resolution and reduce energy consumption.

- Demonstrations of larger build volumes and complex geometries to validate scalability beyond laboratory prototypes.

- Integration with post-processing workflows to address surface finish, mechanical properties, and multi-material printing capabilities.

- Emerging commercial pilot projects or startups leveraging this technology to disrupt rapid manufacturing sectors.

In conclusion, the synthesis of holographic light fields for sub-second volumetric 3D printing represents a significant technological leap with the potential to transform additive manufacturing paradigms. Continued research and development will determine how quickly this promising approach moves from the lab bench to widespread industrial application.