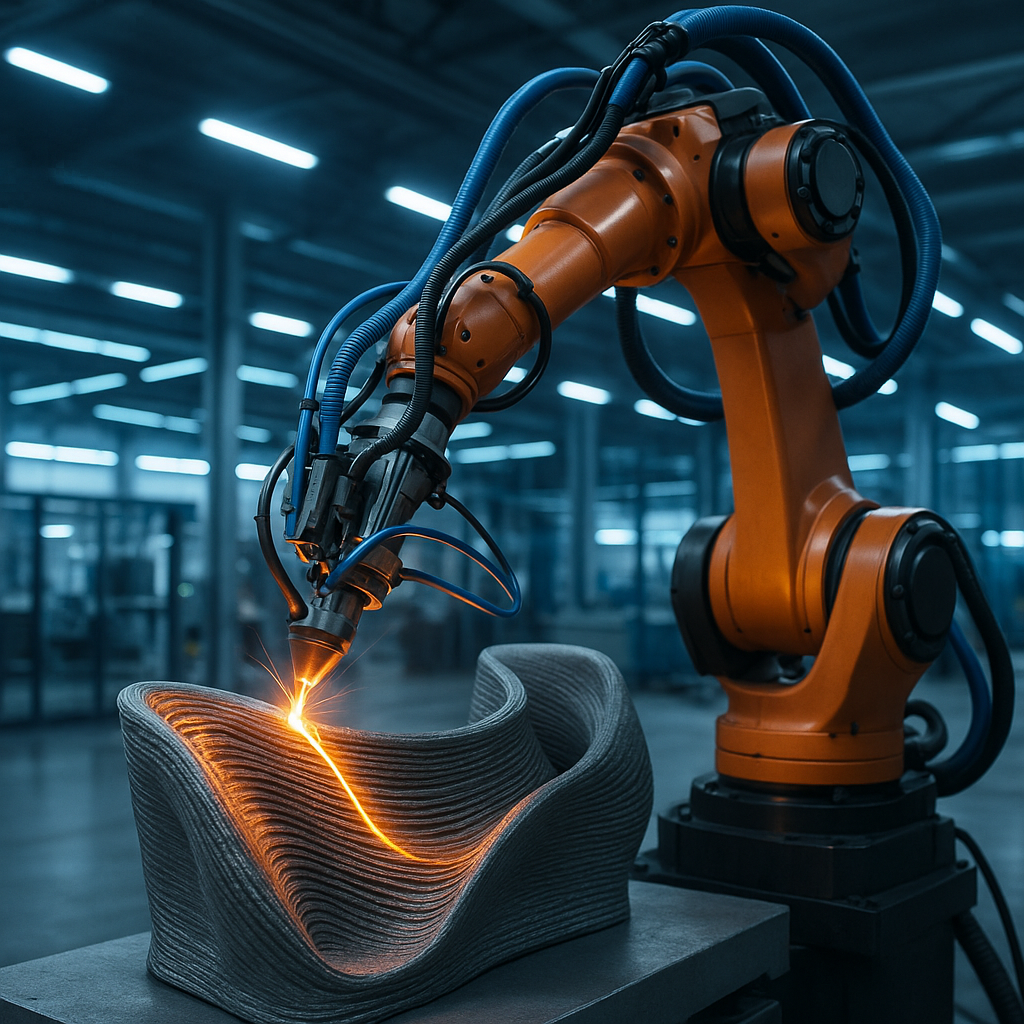

China is witnessing a swift expansion in the adoption of 3D printing technologies across production and daily life, as reported by People’s Daily. This surge notably includes the integration of robotic arm 3D printing, a frontier technique enabling non-planar and multi-axis additive manufacturing that breaks away from traditional layer-by-layer constraints.

What Happened

According to the People’s Daily report, China has rapidly embraced 3D printing technologies, with increasing deployment in both industrial production and consumer applications. Among these advancements, robotic arm 3D printing has gained traction, leveraging multi-axis movement to print on curved, angled, or complex surfaces directly. This approach contrasts with conventional planar 3D printing, which builds objects layer by layer on a fixed horizontal plane.

Why It Matters

The adoption of robotic arm 3D printing in China signals a transformative step in additive manufacturing. Multi-axis printing enables the creation of parts with improved mechanical properties due to continuous, non-planar extrusion paths that reduce layer interfaces and anisotropy. This capability opens doors for producing complex geometries and large-scale parts without the constraints of traditional 3D printer build volumes.

Industrially, this means faster production cycles, reduced post-processing, and the ability to integrate 3D printing into existing robotic assembly lines. For daily life, it suggests more customized and durable products, potentially revolutionizing sectors like automotive, aerospace, medical devices, and consumer goods. China’s rapid scale-up also positions it as a global leader in next-generation additive manufacturing technologies.

Technical Context

Robotic arm 3D printing employs articulated robotic arms equipped with extrusion or deposition tools capable of maneuvering in multiple degrees of freedom—typically six or more axes. This flexibility enables printing on non-flat surfaces and complex geometries, overcoming limitations inherent to traditional gantry-style 3D printers.

Non-planar printing techniques can deposit material continuously along curved paths, reducing the number of weak layer interfaces and improving structural integrity. Multi-axis control also allows for in-situ adjustments to print orientation, optimizing material deposition for stress distribution and surface finish.

Despite these advantages, challenges remain in path planning, real-time process monitoring, and software integration. Precise calibration and synchronization between robotic motion and extrusion parameters are critical. Although the People’s Daily article does not detail specific technical implementations, the reported rapid adoption implies ongoing advancements in these areas within China.

Near-Term Prediction Model

Given the current momentum, robotic arm 3D printing in China is transitioning from pilot to early commercial stages. Within the next 12 to 24 months, we can expect broader industrial deployment, especially in sectors requiring complex, large, or customized components.

Key drivers will include continued improvements in multi-axis motion control, software for non-planar slicing and toolpath generation, and integration with AI-driven process optimization. The impact score for this technology’s industrial influence is high (around 75/100), reflecting its potential to disrupt conventional manufacturing workflows. Confidence in this trajectory is moderate (around 70/100) due to technical and scaling challenges that remain.

What to Watch

- Development of advanced slicing algorithms and software platforms capable of efficiently generating multi-axis, non-planar toolpaths.

- Integration of real-time sensing and closed-loop feedback systems to improve print quality and reduce defects.

- Expansion of industrial pilot projects and case studies demonstrating cost-effectiveness and mechanical advantages over planar printing.

- Policy and investment trends in China supporting additive manufacturing infrastructure and workforce development.

- Collaborations or technology transfers between Chinese manufacturers and global 3D printing innovators focused on robotic arm systems.

While the People’s Daily article highlights the rapid adoption trend, detailed technical data and specific industrial applications remain sparse. Continued monitoring of Chinese industry announcements and research publications will be essential to fully understand the evolving impact of robotic arm 3D printing.