What Happened

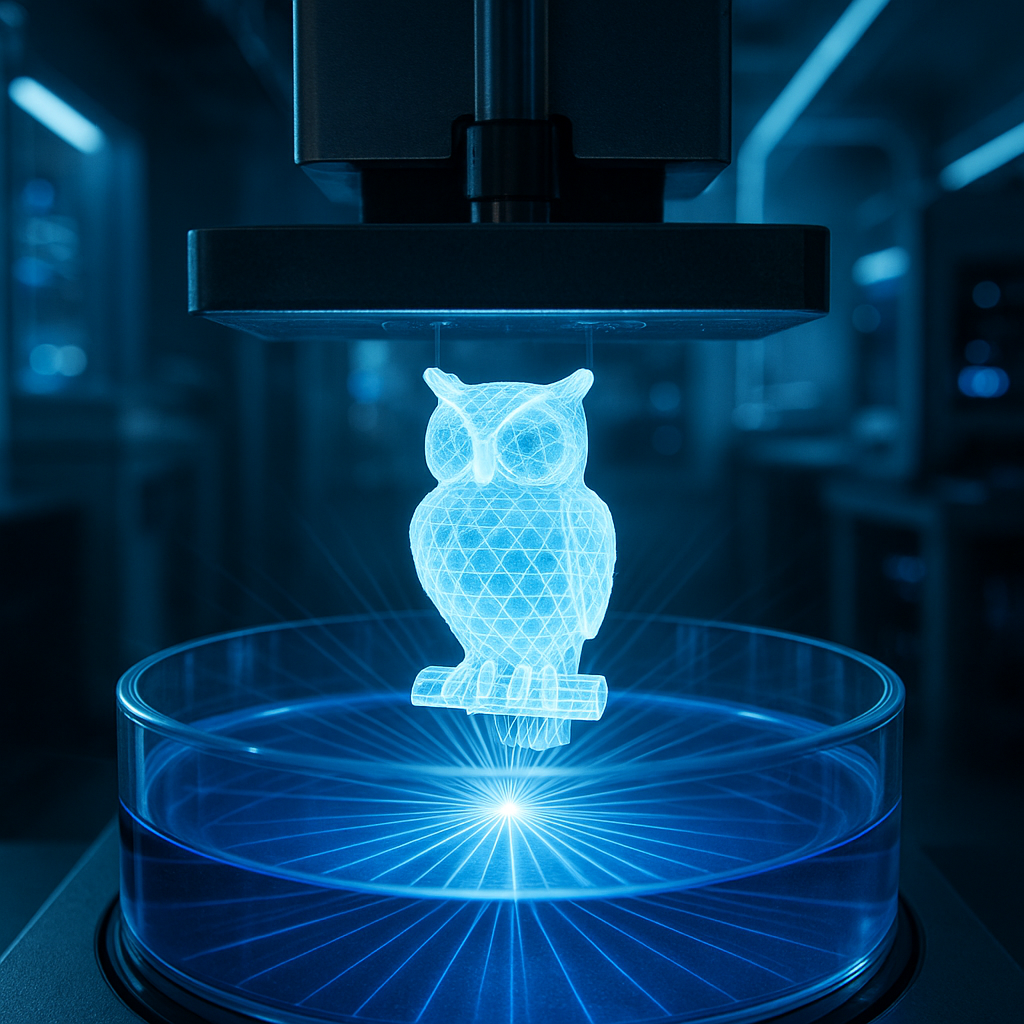

A Chinese research team has made a significant breakthrough in volumetric 3D printing by successfully fabricating millimeter-scale objects in under one second, as reported by VoxelMatters. This development pushes the boundaries of speed and resolution in volumetric 3D printing, a technique that creates objects by curing photosensitive resin simultaneously in three dimensions rather than layer-by-layer.

Why It Matters

This advancement addresses a core limitation in additive manufacturing: speed. Traditional 3D printing methods, including stereolithography and fused deposition modeling, build objects layer by layer, which can be time-consuming for complex geometries. Volumetric 3D printing, by contrast, cures an entire volume at once. Achieving sub-second print times for millimeter-scale objects could revolutionize rapid prototyping, microfabrication, and medical device manufacturing, where speed and precision are paramount.

The ability to produce high-resolution objects so quickly opens new possibilities for on-demand manufacturing and potentially real-time customization. It could also reduce production bottlenecks in industries requiring intricate small parts, such as electronics, microfluidics, and biomedical implants.

Technical Context

Volumetric 3D printing leverages the principle of volumetric photopolymerization, where light patterns are projected into a rotating volume of photosensitive resin. The intersection of these light patterns cures the resin simultaneously in three dimensions, forming a solid object without the need for layer-by-layer construction.

The Chinese team’s achievement of printing millimeter-scale objects in under one second indicates significant advancements in several technical aspects:

- Light modulation and projection: Faster and more precise control of light intensity and patterning is required to cure resin rapidly and accurately.

- Resin chemistry: Development or optimization of photopolymers that cure quickly with minimal oxygen inhibition and high resolution.

- System synchronization: Precise coordination between resin rotation, light projection, and curing dynamics to avoid defects and ensure dimensional accuracy.

While the report highlights the speed and scale, details such as the exact resolution, mechanical properties of the printed parts, and scalability to larger objects remain unknown. Further technical disclosures will be necessary to fully assess the robustness and versatility of this approach.

Near-Term Prediction Model

Given the current state of volumetric 3D printing and the reported breakthrough, the technology is likely in the late research and early pilot phase. Over the next 12 to 24 months, we can anticipate the following developments:

- Refinement of resin formulations to balance speed, resolution, and material properties suitable for diverse applications.

- Improved hardware integration for better control of light projection and volume rotation, enhancing print quality and repeatability.

- Demonstrations of practical use cases in microfabrication, particularly in biomedical devices or micro-optics, where rapid turnaround is critical.

Commercial adoption will depend on overcoming challenges such as scaling the process for larger parts, ensuring consistent mechanical performance, and cost-effectiveness compared to existing technologies.

What to Watch

- Publication of detailed technical papers or patents by the Chinese team elucidating the underlying methods and materials.

- Emergence of startups or established 3D printing companies integrating volumetric printing for rapid microfabrication.

- Demonstrations of volumetric printing applied to biomedical implants, microfluidic devices, or electronics components.

- Advances in resin chemistry that enable faster curing without compromising mechanical strength or biocompatibility.

- Development of scalable volumetric printing systems capable of producing larger or multi-material objects.

In summary, this breakthrough represents a meaningful leap in volumetric 3D printing speed and precision. While still early in development, the implications for rapid manufacturing and high-resolution microfabrication are substantial and warrant close observation.