Elegoo has launched a new fiber-reinforced filament series aimed at enhancing the strength, intelligence, and versatility of FDM 3D printing, as reported by PR Newswire UK on June 24, 2025.

What Happened

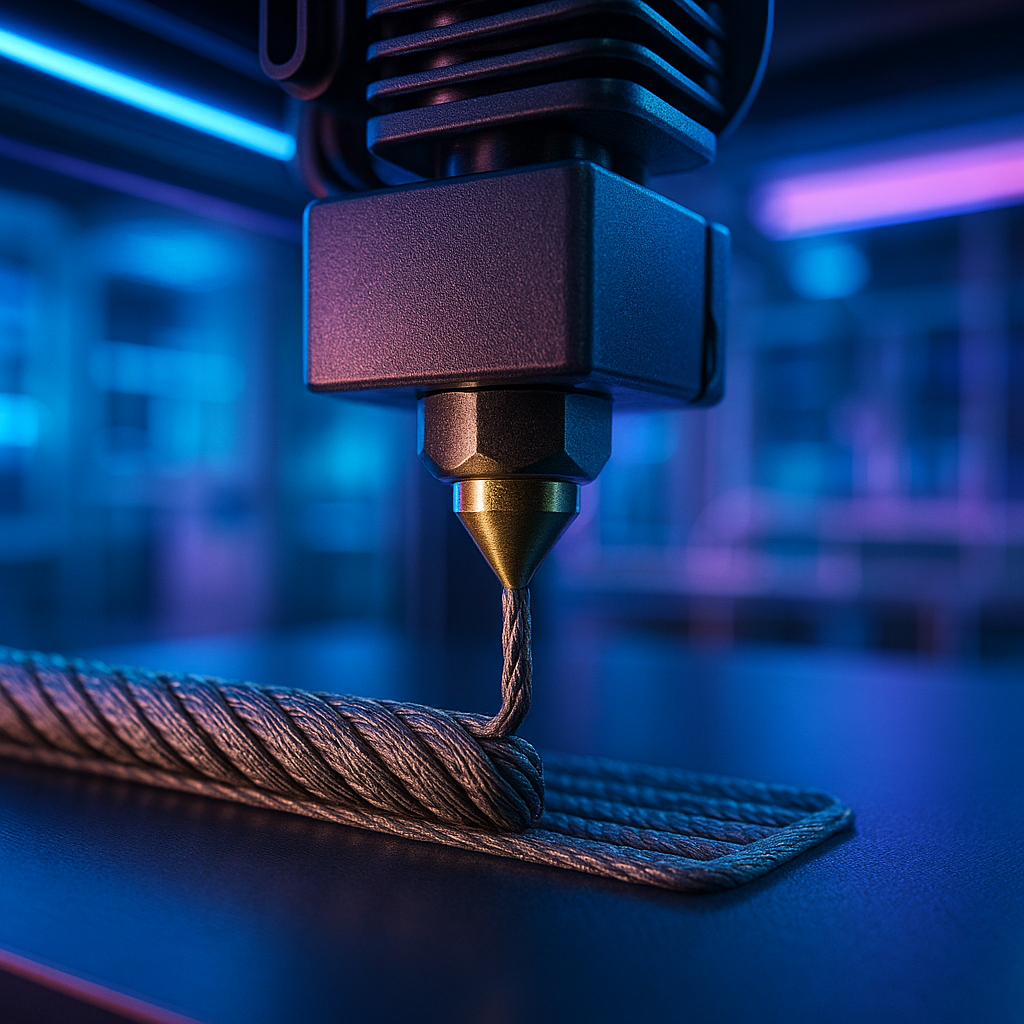

Elegoo, a notable player in the 3D printing market, unveiled a series of fiber-reinforced filaments designed to elevate fused deposition modeling (FDM) printing capabilities. This new filament series integrates fiber materials into traditional polymer matrices, resulting in enhanced mechanical strength and durability. The announcement highlights the filaments’ potential to deliver smarter and more versatile printing solutions, though detailed technical specifications remain limited in the public domain.

Why It Matters

The introduction of fiber-reinforced smart filaments is significant for multiple reasons. First, it addresses a longstanding limitation in FDM printing: the relative weakness and brittleness of printed parts compared to those made by other additive manufacturing methods or traditional manufacturing. By reinforcing filaments with fibers, Elegoo is pushing the boundaries of what FDM printers can achieve in terms of structural integrity.

Second, the term “smarter” in the announcement suggests these filaments may incorporate or enable enhanced functionalities beyond mechanical strength, potentially including improved thermal stability, dimensional accuracy, or responsiveness to environmental stimuli. This aligns with the broader trend of embedding intelligence into printing materials, which could lead to parts that self-monitor, self-heal, or adapt to conditions.

Technical Context

Fiber reinforcement in 3D printing filaments is not entirely new but remains an evolving frontier. Common fibers used include carbon, glass, and aramid, each contributing unique properties such as increased tensile strength, stiffness, and heat resistance. The challenge lies in uniformly dispersing fibers within the polymer matrix and ensuring compatibility with FDM printers to avoid nozzle clogging or print defects.

Elegoo’s announcement does not specify the fiber types or polymer bases used, nor the fiber loading percentages, which are critical to understanding performance trade-offs such as printability versus mechanical gains. Additionally, the “smart” aspect could refer to embedded sensors, conductive pathways, or stimuli-responsive materials, though no explicit details are provided.

Near-Term Prediction Model

Given the commercial launch, Elegoo’s fiber-reinforced smart filaments are likely in the early commercialization stage, with adoption initially concentrated among hobbyists, educators, and small-scale industrial users seeking improved part performance. Over the next 12 to 24 months, expect incremental refinements in filament formulations and printer compatibility, accompanied by expanded application use cases such as functional prototypes, tooling, and lightweight structural components.

Challenges remain in balancing fiber content for printability and mechanical benefits, cost competitiveness, and educating users on optimal print settings. If Elegoo can demonstrate clear advantages and ease of use, market penetration could accelerate, influencing competitors to innovate similarly.

What to Watch

- Technical disclosures from Elegoo detailing fiber types, loading ratios, and the nature of the “smart” properties embedded in the filaments.

- User feedback and independent testing results assessing mechanical performance, print quality, and durability compared to existing fiber-reinforced and standard filaments.

- Expansion of compatible FDM printers and slicer software optimizations tailored for fiber-reinforced smart filaments.

- Emerging applications that leverage the smart capabilities of these materials, such as embedded sensing or adaptive components.

- Competitive responses from other filament manufacturers and potential partnerships with printer OEMs to co-develop integrated solutions.

In conclusion, Elegoo’s fiber-reinforced smart filament series marks an important step toward smarter, stronger FDM 3D printing materials. While detailed technical information is still forthcoming, this development reflects a growing industry focus on enhancing filament functionality and broadening the scope of additive manufacturing applications.