In the evolving landscape of 3D printing, hybrid materials are gaining traction as innovative alternatives to classic filaments. A recent article from 3Dnatives highlights the rise of these materials, particularly conductive filaments, which are spearheading the integration of smart and bio-embedded functionalities into 3D printed objects.

What Happened

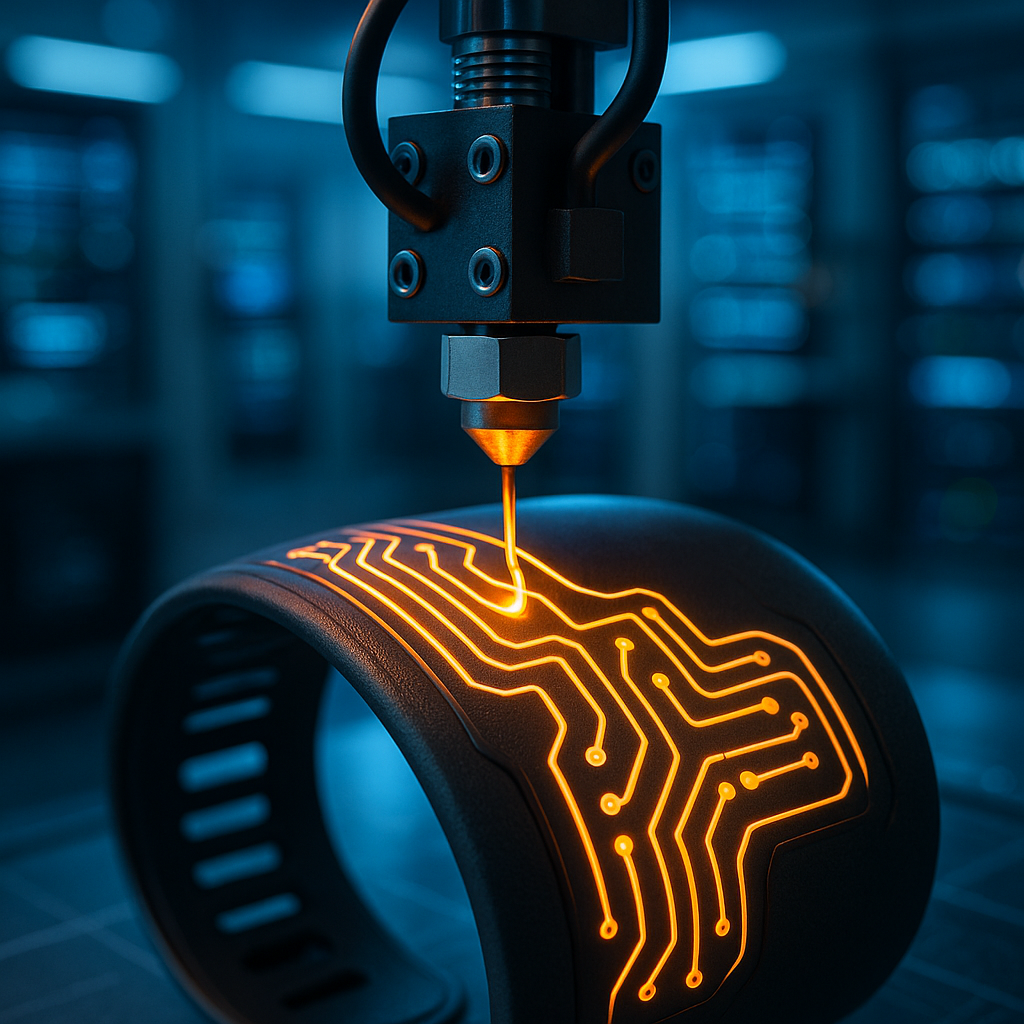

Hybrid filaments, including conductive filaments, are increasingly being developed and adopted as replacements for traditional PLA, ABS, and PETG materials. These filaments blend polymers with conductive additives such as carbon nanotubes, graphene, or metal particles, enabling the printed parts to conduct electricity. This innovation paves the way for 3D printed objects to incorporate sensors, circuits, or bio-interactive elements directly within the print, bypassing the need for post-print assembly.

Why It Matters

The integration of conductive filaments into 3D printing workflows represents a significant leap toward multifunctional, smart devices that can be custom-fabricated with embedded electronics. This capability is particularly transformative for wearable technology, biomedical devices, robotics, and IoT components, where lightweight, flexible, and personalized parts are essential. Moreover, embedding conductive pathways directly into structures reduces assembly complexity and enhances durability.

Technical Context

Conductive filaments are typically composites, combining a base thermoplastic polymer with conductive fillers. The challenge lies in balancing printability, mechanical strength, and electrical conductivity. High filler content improves conductivity but can degrade filament flexibility and extrusion quality. Manufacturers are experimenting with varying filler types and concentrations to optimize these properties.

Additionally, printing parameters such as nozzle temperature, print speed, and layer height require fine-tuning to accommodate the unique behavior of conductive filaments. The anisotropic nature of printed layers can also affect electrical performance, necessitating design considerations to ensure reliable conductivity along intended paths.

Near-term Prediction Model

Over the next 12 to 18 months, conductive filament technology is expected to transition from pilot to early commercial maturity. As manufacturers refine formulations and printers become more adept at handling hybrid materials, adoption will grow in niche applications such as prototyping smart wearables and low-power embedded sensors. However, widespread use in mass production remains limited by cost and performance constraints.

Material suppliers will likely focus on improving filament consistency and conductivity while maintaining ease of printing. Concurrently, 3D printer makers may introduce hardware and software enhancements tailored for conductive materials, such as specialized extruders and slicing algorithms that optimize electrical pathways.

What to Watch

- Development of standardized testing methods for electrical and mechanical properties of conductive filaments.

- Emergence of bio-compatible conductive filaments enabling direct printing of bio-embedded sensors or tissue interfaces.

- Collaborations between filament producers and 3D printer manufacturers to optimize hardware-software integration for hybrid materials.

- Innovations in multi-material printing allowing simultaneous deposition of conductive and insulating filaments within a single print.

- Expansion of application case studies demonstrating real-world benefits in healthcare, robotics, and wearable tech.

While the current landscape shows promising progress, some details remain unclear, including long-term durability of conductive prints under mechanical stress and environmental exposure. Additionally, the economic feasibility of scaling production for conductive filaments is yet to be fully established.

In summary, conductive filaments are a frontier technology within the broader category of smart and bio-embedded 3D printing materials. Their continued development promises to unlock new possibilities in additive manufacturing, transforming how electronics and biological functions are integrated into printed objects.