What Happened

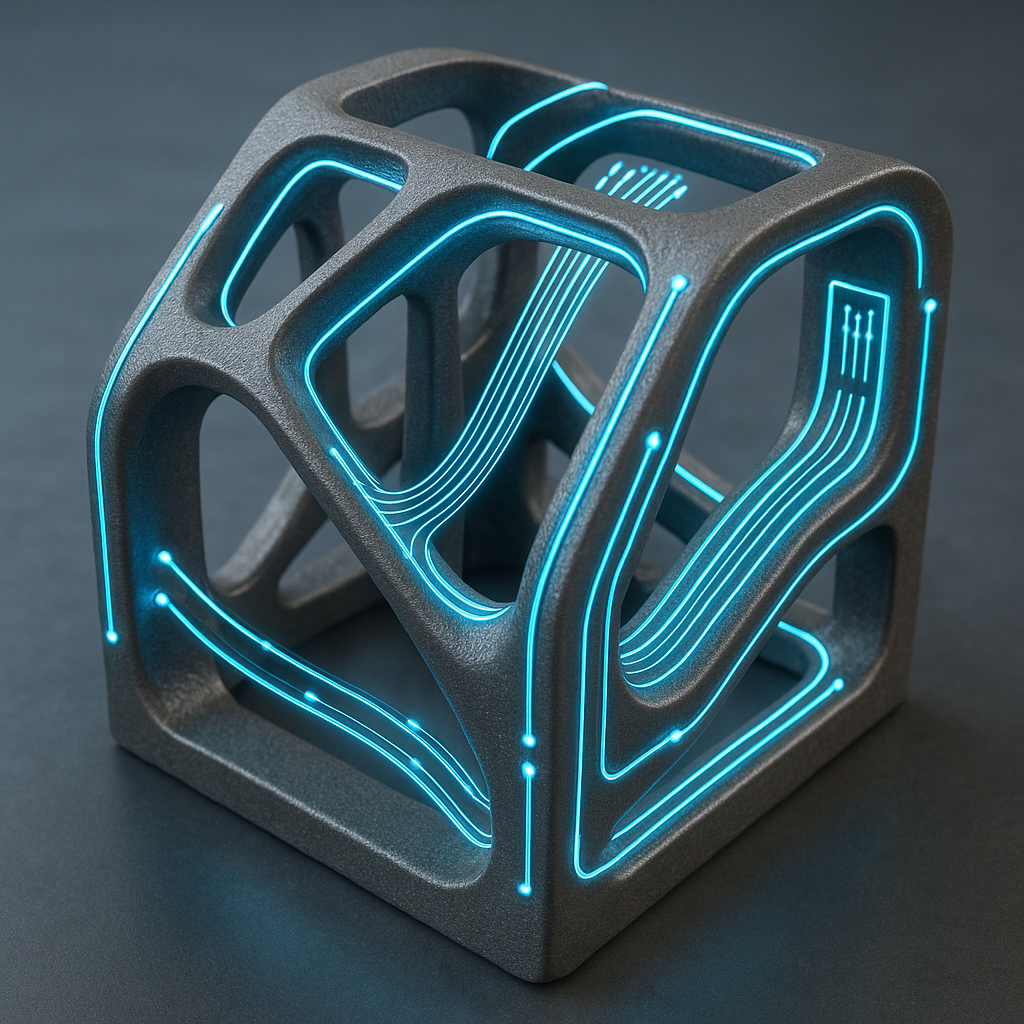

In a significant development at the intersection of additive manufacturing and smart materials, Fabrisonic and Luna Innovations have collaborated to produce 3D printed smart structures embedded with fiber optic sensors. As reported by 3DPrint.com, this pioneering effort integrates fiber optic sensor technology directly into metal structures during the 3D printing process, enabling real-time monitoring of structural health and environmental conditions.

Why It Matters

The integration of embedded fiber optic sensors into 3D printed components represents a leap forward in smart material design and manufacturing. This technology allows for continuous, real-time sensing capabilities within structural parts, which is crucial for applications requiring high reliability and safety, such as aerospace, automotive, and infrastructure. Embedding sensors directly during the printing process eliminates the need for post-production sensor installation, reducing assembly complexity and potential failure points.

Furthermore, this approach enhances the functionality of 3D printed parts beyond their mechanical properties, transforming them into intelligent systems capable of self-monitoring. This capability is vital for predictive maintenance, reducing downtime, and extending the lifecycle of critical components.

Technical Context

Fabrisonic employs ultrasonic additive manufacturing (UAM), a solid-state 3D printing technique that uses high-frequency ultrasonic vibrations to bond metal foils layer by layer at relatively low temperatures. This method preserves the integrity of embedded components, such as fiber optic sensors, which are sensitive to high heat and mechanical stresses common in traditional metal additive manufacturing processes like laser powder bed fusion.

Luna Innovations contributes advanced fiber optic sensing technology known for its high sensitivity, immunity to electromagnetic interference, and capability to measure strain, temperature, and other physical parameters along the sensor’s length. By embedding these sensors within metal structures during UAM, the resulting parts gain distributed sensing capabilities without compromising structural integrity.

Details about the specific sensor configurations, data acquisition systems, and integration challenges remain limited in the public domain. It is also unclear how these embedded sensors perform over extended operational cycles or under extreme environmental conditions.

Near-Term Prediction Model

The technology is currently in the pilot stage, with demonstrated proof-of-concept structures showcasing embedded fiber optic sensors within 3D printed metal parts. Given the specialized nature of ultrasonic additive manufacturing and the niche application of fiber optic sensors, broader commercial adoption is anticipated within 24 to 36 months, primarily targeting high-value sectors such as aerospace, defense, and energy.

As manufacturing processes mature and sensor integration techniques improve, we expect to see increased development of smart components capable of self-diagnosis and condition monitoring. This will likely drive demand for customized sensor-embedded parts and stimulate innovation in sensor miniaturization and data analytics integration.

What to Watch

- Advancements in ultrasonic additive manufacturing scalability and cost-efficiency.

- Performance data from long-term operational testing of embedded fiber optic sensors in various environments.

- Expansion of embedded sensor types beyond fiber optics, including bio-compatible sensors for medical or bio-embedded applications.

- Development of integrated software platforms for real-time data processing and predictive analytics from embedded sensors.

- Collaborations or partnerships between additive manufacturing firms and sensor technology companies to accelerate commercialization.

Overall, the Fabrisonic and Luna Innovations collaboration marks a promising advancement in the smart materials domain, potentially transforming how industries design, monitor, and maintain critical structures.