What Happened

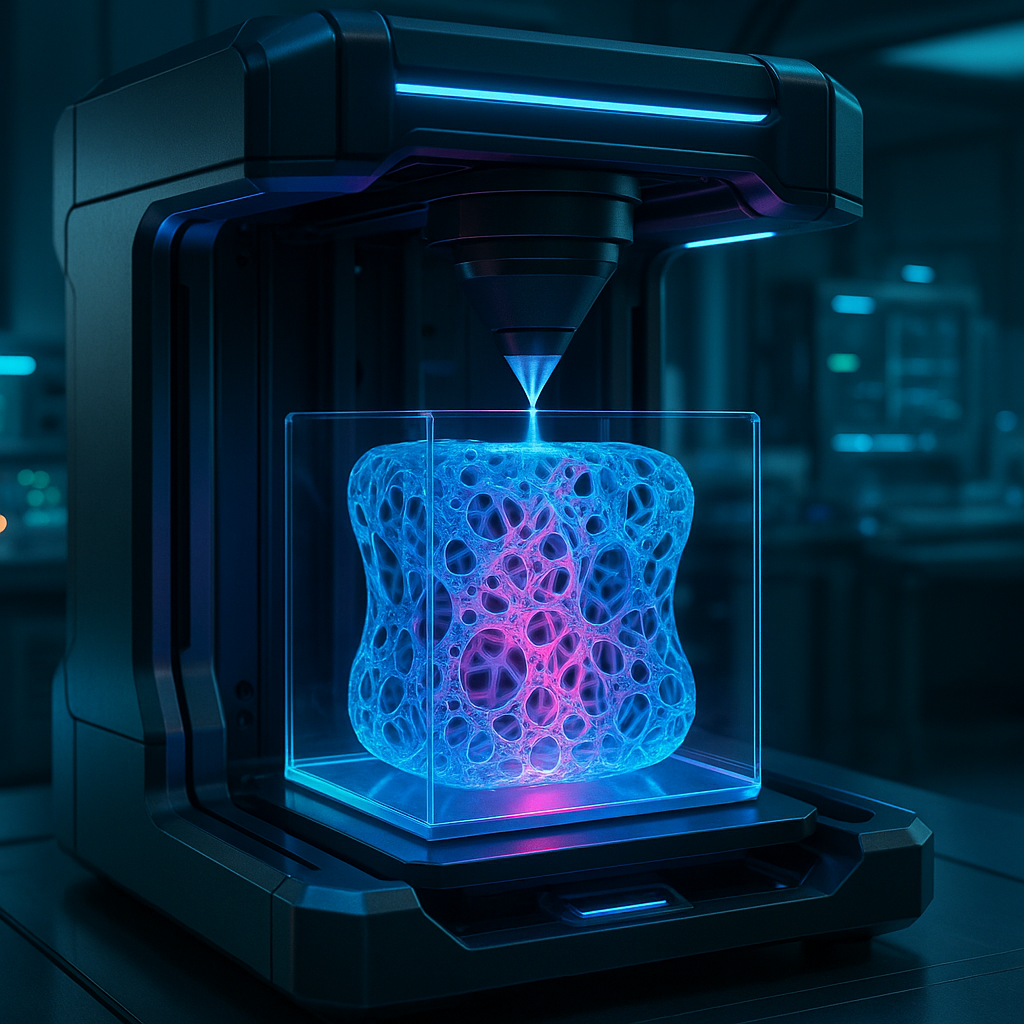

Recent advancements in volumetric 3D printing have unlocked the ability to fabricate hydrogel-infused composite materials, marking a significant breakthrough in the field. According to a report by openPR.com dated February 11, 2026, researchers have demonstrated that volumetric 3D printing can now incorporate hydrogels into composite structures, enabling faster, more complex, and biocompatible prints that were previously unattainable.

Why It Matters

This development is poised to revolutionize industries reliant on 3D printing by merging the speed and resolution advantages of volumetric printing with the unique properties of hydrogels. Hydrogels are prized for their water retention, biocompatibility, and tunable mechanical properties, making them ideal for biomedical applications such as tissue engineering, drug delivery systems, and soft robotics.

By integrating hydrogels into volumetric printing processes, manufacturers can create composite materials that combine rigid and soft phases in a single print, opening doors to new product designs and functionalities. This could lead to breakthroughs in personalized medicine, including patient-specific implants and scaffolds that closely mimic natural tissue environments.

Technical Context

Volumetric 3D printing differs from traditional layer-by-layer additive manufacturing by curing an entire volume simultaneously using intersecting light fields, drastically reducing print times and enabling complex geometries without support structures. Historically, volumetric printing has been limited by the types of materials that can be cured rapidly and uniformly in 3D space.

The incorporation of hydrogels into volumetric printing presents unique challenges, such as maintaining hydrogel integrity during curing and achieving uniform composite distribution. The breakthrough reported involves novel photopolymerizable hydrogel formulations and optimized light exposure protocols that preserve hydrogel properties while ensuring structural stability.

Details on the exact chemical compositions or printing parameters remain undisclosed, but the achievement suggests significant progress in material science and photopolymer chemistry tailored for volumetric methods.

Near-Term Prediction Model

Currently at an advanced research and pilot phase, hydrogel-infused volumetric printing is expected to transition toward early commercial applications within 12 to 24 months. Initial use cases will likely focus on biomedical devices and soft robotics prototypes where the material advantages justify the complexity and cost.

As formulations mature and printing hardware adapts to handle these composites reliably, adoption will broaden into industrial manufacturing sectors requiring multifunctional materials with embedded soft components. However, widespread commercial deployment may take 3 to 5 years, contingent on regulatory approvals, reproducibility, and cost optimization.

What to Watch

- Publication of detailed methodologies and material compositions enabling hydrogel integration in volumetric printing.

- Development of commercial volumetric printers explicitly designed or adapted for hydrogel composite fabrication.

- Regulatory progress in biomedical applications using volumetrically printed hydrogel composites.

- Collaborations between material scientists, biomedical engineers, and 3D printing hardware manufacturers to scale production.

- Emergence of new applications in soft robotics and wearable devices leveraging the unique properties of these composites.

While the initial breakthrough is promising, the pace of commercialization and the range of viable applications will depend heavily on overcoming current technical constraints and achieving consistent quality control.

In summary, the integration of hydrogels into volumetric 3D printing represents a frontier with transformative potential, blending rapid manufacturing with advanced material functionality. Stakeholders across healthcare, manufacturing, and research should monitor this evolving technology closely.