What Happened

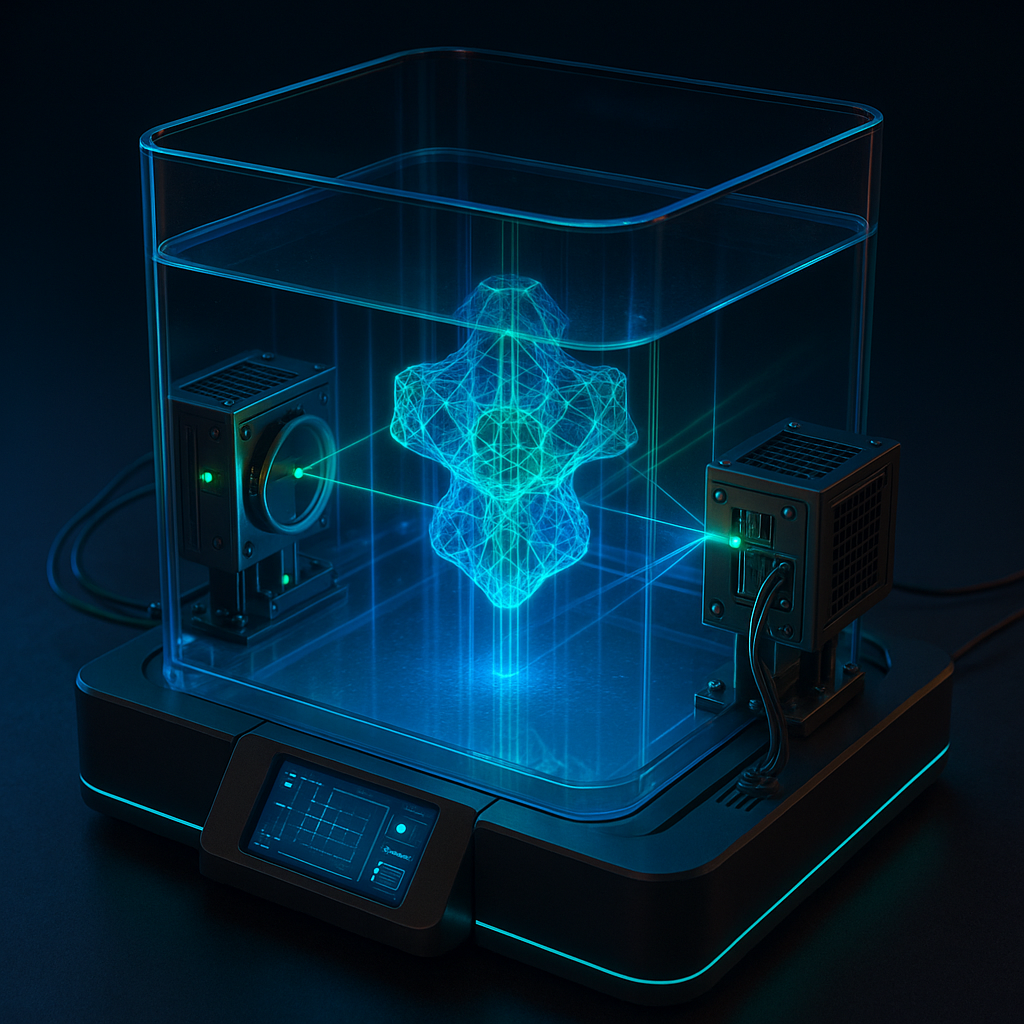

A recent development reported by 3D Printing Industry highlights a new MEMS-based holographic system designed to boost the efficiency of volumetric 3D printing. This innovation leverages microelectromechanical systems (MEMS) to dynamically control holographic light patterns, enabling more precise and rapid curing of photosensitive resins in volumetric printing processes, specifically tomographic printing.

Why It Matters

Volumetric 3D printing, especially tomographic printing, represents a paradigm shift from traditional layer-by-layer additive manufacturing. Instead of building objects slice by slice, volumetric printing cures entire 3D volumes simultaneously by projecting light patterns from multiple angles. This can drastically reduce print times and produce objects with isotropic mechanical properties and complex geometries without the need for support structures.

The integration of MEMS-based holographic systems addresses one of the critical bottlenecks in volumetric printing: the precise and efficient delivery of complex light patterns. By enabling dynamic, high-resolution control of light projection, this technology improves printing speed, resolution, and energy efficiency. This advancement could accelerate the adoption of volumetric printing for industrial applications where speed and precision are paramount.

Technical Context

Tomographic volumetric printing relies on the principle of computed tomography but in reverse. Instead of reconstructing an image from projections, it builds a 3D object by projecting computed light dose distributions into a rotating volume of photopolymer resin. The challenge lies in generating the required complex light fields with high fidelity and speed.

Traditional volumetric systems often use digital micromirror devices (DMDs) or spatial light modulators (SLMs) to pattern light, but these can be limited in speed, resolution, or optical efficiency. MEMS-based holographic systems employ micro-scale mechanical components to modulate light waves more precisely and rapidly. Holography allows control not only of intensity but also phase and direction of light, enabling complex 3D dose patterns to be formed in the resin volume.

This MEMS approach can improve scanning speeds and reduce optical losses, which translates into faster curing times and higher resolution prints. However, the exact specifications, such as resolution limits, power handling, and integration complexity, were not detailed in the source article.

Near-Term Prediction Model

Given the current state of volumetric printing and MEMS technology, this MEMS-based holographic system is likely in the late research and early pilot phase. The technology shows promise for commercial viability within the next 12 to 24 months, especially for niche applications requiring rapid prototyping of complex geometries.

Its impact score is moderate to high (~75/100) because it addresses a key limitation in volumetric printing but still requires further engineering for robustness, cost-effectiveness, and scalability. Confidence in this timeline is moderate (~70/100) due to typical challenges in MEMS manufacturing and system integration.

What to Watch

- Demonstrations of full-scale volumetric printers incorporating MEMS holographic modules with real-world materials.

- Performance benchmarks comparing MEMS holography to existing DMD and SLM systems in terms of resolution, speed, and energy consumption.

- Advances in photopolymer resin chemistry optimized for holographic curing to maximize print quality and mechanical properties.

- Cost reduction and manufacturability improvements for MEMS devices tailored to volumetric printing.

- Emerging industrial adoption cases in medical devices, microfluidics, or aerospace components where volumetric printing offers unique advantages.

While the article does not specify these details, these areas will be critical to watch for assessing the broader impact and commercial readiness of MEMS-enhanced volumetric printing.