What happened

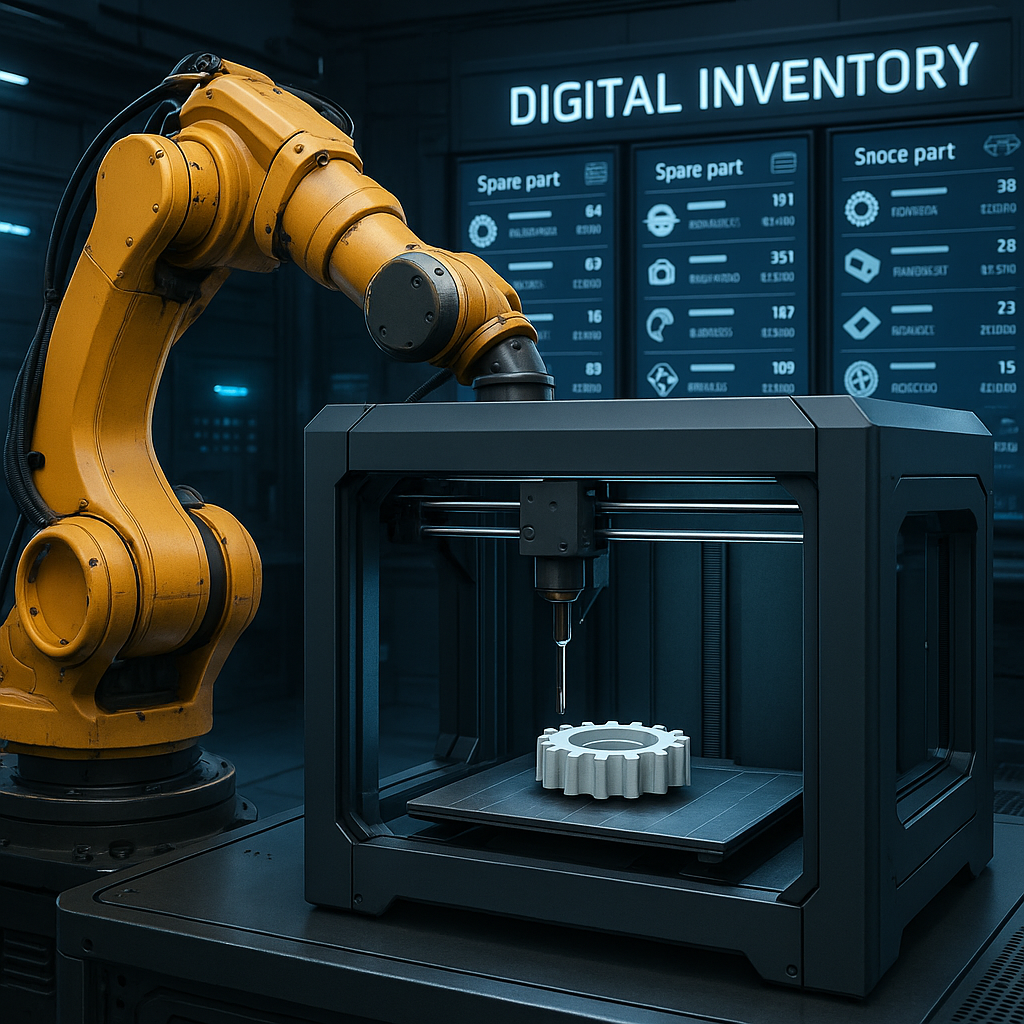

A recent article from eurekamagazine.co.uk highlights the growing integration of automation and additive manufacturing (3D printing) within robotics. This convergence is enabling new approaches to spare parts management, particularly the concept of on-demand spares. Instead of relying on extensive physical inventories, robotics manufacturers and operators are increasingly leveraging digital inventories paired with additive manufacturing to produce replacement parts as needed. This shift is poised to redefine supply chains and maintenance protocols across industries dependent on robotics.

Why it matters

The ability to produce spares on demand is a game changer for robotics and related sectors. Traditional spare parts supply chains often involve long lead times, high inventory carrying costs, and vulnerability to disruptions. By embedding additive manufacturing capabilities and automation into the robotics ecosystem, companies can drastically reduce downtime and costs associated with spare parts logistics. This digital inventory approach also enhances sustainability by minimizing overproduction and waste. Moreover, it supports greater customization and rapid iteration, which are critical in fast-evolving technology landscapes.

Technical context

At the core of this transformation is the synergy between automation technologies and advanced additive manufacturing methods such as selective laser sintering (SLS), fused filament fabrication (FFF), and multi-material printing. Robotics systems equipped with automated quality control and integrated 3D printing cells can autonomously manufacture spares tailored to specific requirements. Digital inventory platforms store validated 3D CAD models of parts, enabling immediate retrieval and production without the need for physical stockpiles. However, challenges remain in material properties matching, certification of printed parts for safety-critical applications, and integration of real-time monitoring data to predict spare needs accurately.

Near-term prediction model

Over the next 12 to 24 months, this technology is expected to move from pilot implementations toward broader commercial adoption. Early adopters in industrial robotics, aerospace, and automotive sectors are likely to lead, driven by the critical need for operational continuity and cost reduction. Advances in materials science and process standardization will improve the reliability and certification processes for printed spares. Additionally, AI-driven predictive maintenance tools will increasingly inform digital inventory management, optimizing when and what to print. However, widespread adoption depends on overcoming regulatory hurdles and proving long-term durability of additive parts under operational stresses.

What to watch

- Development of industry standards and certifications for 3D printed spare parts in robotics.

- Integration of AI and IoT data streams with digital inventory platforms to enhance predictive maintenance accuracy.

- Material innovation enabling printed parts to meet or exceed traditional manufacturing quality and durability.

- Case studies and pilot projects demonstrating cost savings and downtime reduction through on-demand spares.

- Expansion of automated additive manufacturing cells within robotics production and maintenance facilities.

While the article from eurekamagazine.co.uk outlines the broad potential, specific details on implementation timelines and operational results remain limited. Continued monitoring of pilot programs and emerging partnerships will be critical to understanding the practical impact of this technological frontier.