What Happened

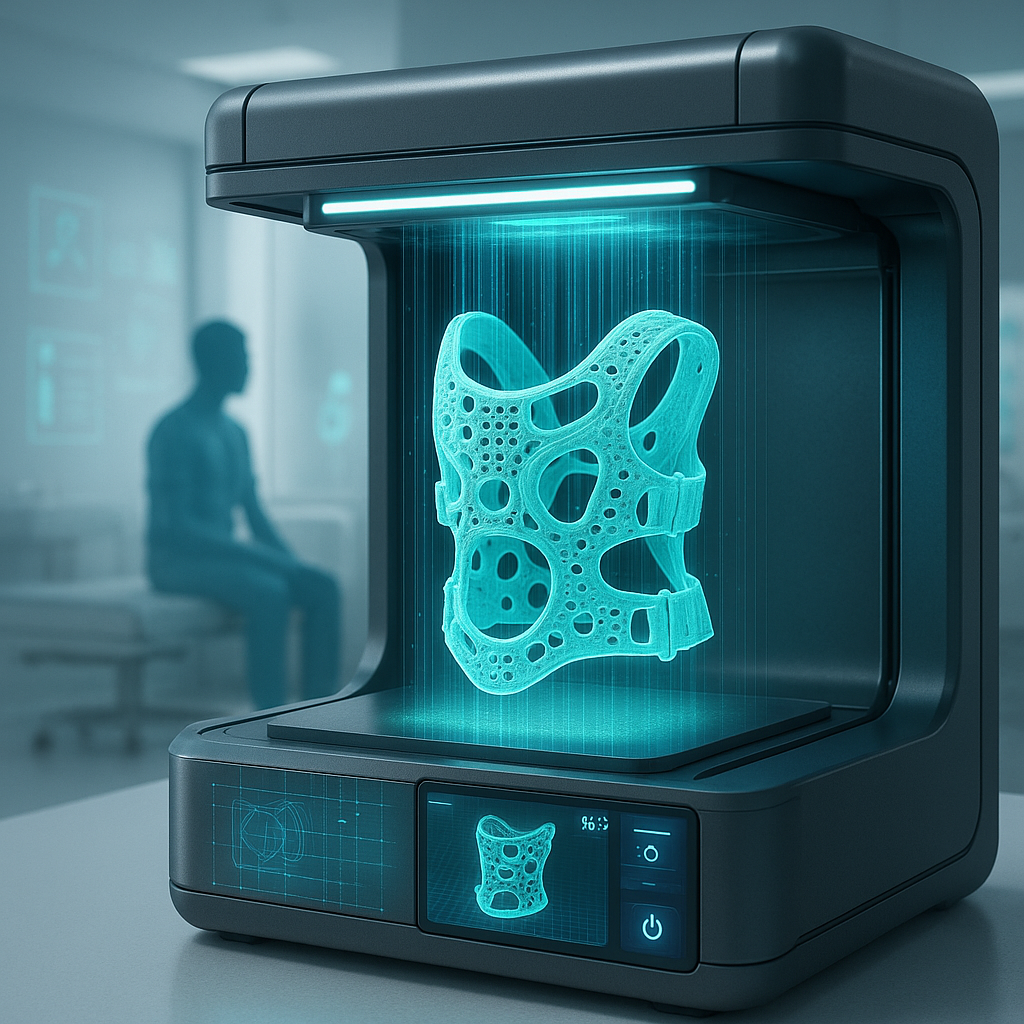

PERFI, a pioneering startup, has launched a volumetric 3D printing platform aimed at transforming the production of personalized medical devices. This development was recently highlighted in a 3Dnatives article, which details the platform’s capabilities in delivering rapid, volumetric 3D printing for bespoke medical solutions. While specifics on the platform’s technical specifications remain limited, the announcement positions PERFI at the forefront of volumetric additive manufacturing applied to healthcare.

Why It Matters

Personalized medical devices—ranging from implants to prosthetics—require precise customization to patient anatomy, often demanding time-consuming and costly manufacturing processes. Volumetric 3D printing, which builds entire 3D objects simultaneously by projecting light patterns into a photosensitive resin, offers a paradigm shift by drastically reducing production times and improving geometric complexity beyond traditional layer-by-layer methods.

PERFI’s platform could significantly accelerate the availability of patient-specific devices, potentially improving clinical outcomes and reducing healthcare costs. This innovation is particularly relevant for urgent medical conditions where device customization speed is critical. Additionally, volumetric printing’s ability to produce complex internal structures may enable novel device functionalities not achievable with conventional manufacturing.

Technical Context

Volumetric 3D printing differs fundamentally from standard additive manufacturing techniques such as fused deposition modeling (FDM) or stereolithography (SLA). Instead of building parts layer-by-layer, volumetric printing uses computed tomography-inspired light projections to polymerize resin within a rotating vat, creating the entire 3D geometry in seconds to minutes. This approach eliminates layer lines, reduces mechanical anisotropy, and can fabricate complex geometries with internal channels or overhangs without support structures.

Challenges in volumetric printing typically include material limitations, resolution constraints, and the need for precise control over light dose and resin chemistry. PERFI’s platform likely addresses these through proprietary hardware and software integration, although detailed information on their materials, resolution capabilities, and post-processing requirements is currently unavailable. The platform’s suitability for medical-grade materials and regulatory compliance will be critical for clinical adoption.

Near-Term Prediction Model

Given the current information, PERFI’s volumetric 3D printing platform appears to be in the pilot to early commercial stage, targeting personalized medical devices. Within the next 12 to 24 months, we anticipate incremental adoption in niche medical applications such as hearing aids, dental devices, or custom surgical guides, where rapid turnaround and customization are highly valued.

Broader clinical deployment will depend on validation studies, regulatory approvals, and demonstration of material biocompatibility. The impact on the medical device manufacturing landscape could be substantial if PERFI successfully scales production and integrates with existing healthcare workflows.

What to Watch

- Technical validation: Independent studies demonstrating the mechanical properties, biocompatibility, and precision of devices produced by PERFI’s platform.

- Regulatory milestones: Approvals or clearances from agencies such as the FDA or EMA for medical device manufacturing using volumetric 3D printing.

- Material development: Expansion of compatible resin formulations tailored for specific medical applications.

- Market partnerships: Collaborations with medical device companies or healthcare providers to pilot and scale personalized device production.

- Competitive landscape: Emergence of other volumetric printing startups or established manufacturers entering this space, influencing PERFI’s market positioning.

In conclusion, PERFI’s volumetric 3D printing platform represents a promising advancement in personalized medical device manufacturing, leveraging cutting-edge additive technology to address critical needs in healthcare customization and speed. While many technical and regulatory details remain to be disclosed, the potential impact warrants close monitoring as the technology matures and moves toward broader clinical use.