What Happened

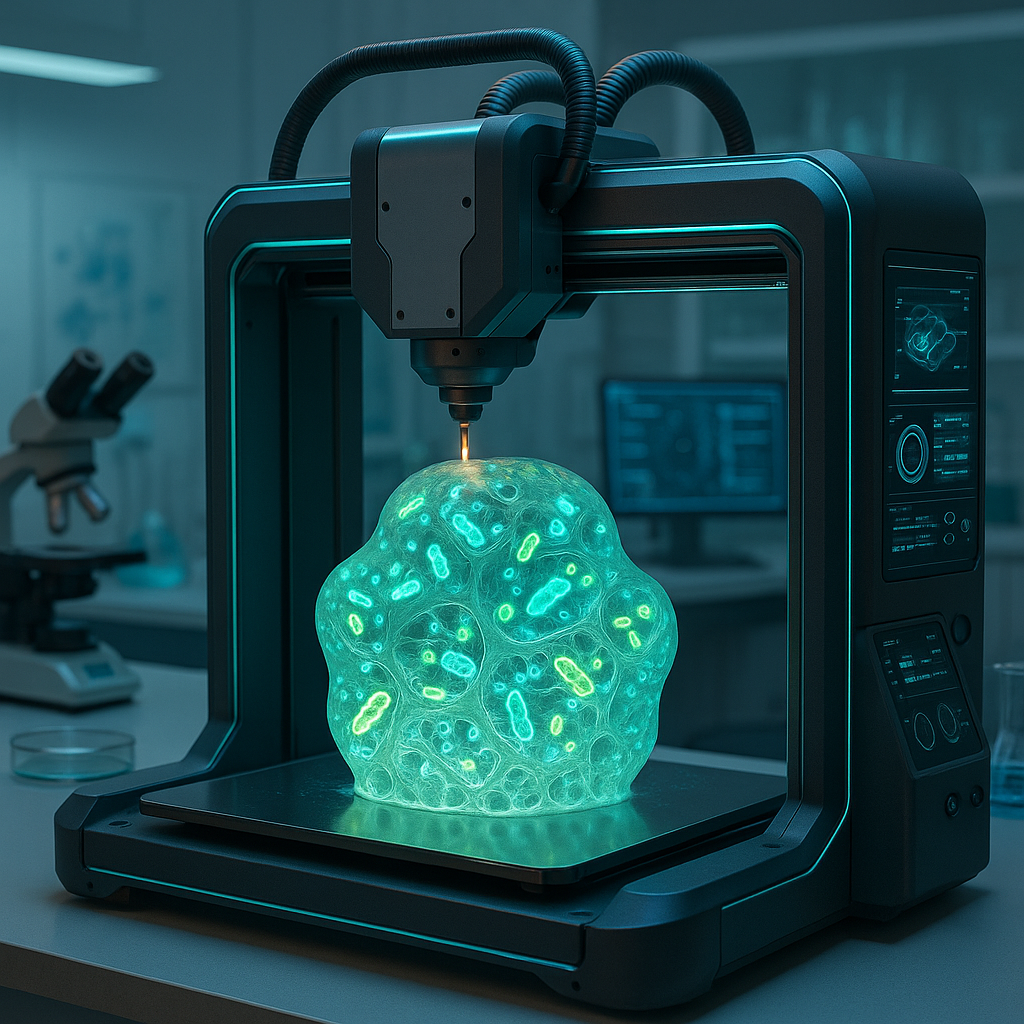

Researchers have demonstrated a groundbreaking technique of 3D printing bacteria into functional complex materials, as reported by Science | AAAS. This novel approach integrates living bacteria within printed constructs, enabling the creation of bio-embedded materials that are capable of performing diverse, programmable functions. Unlike traditional inert 3D printed objects, these living materials actively respond to their environment or execute biochemical tasks, marking a significant leap forward in biomanufacturing and material science.

Why It Matters

The ability to 3D print living bacteria into complex architectures opens new frontiers in smart materials and synthetic biology. Living materials can self-heal, sense environmental changes, produce useful chemicals, or even degrade pollutants, which is impossible with conventional materials. Embedding living cells directly during the printing process enhances spatial control and functional integration, potentially revolutionizing sectors such as environmental remediation, healthcare, wearable biosensors, and bioelectronics. This method also paves the way for scalable manufacturing of living systems with intricate designs tailored to specific tasks, enabling a new class of adaptive, sustainable technologies.

Technical Context

Traditional 3D printing focuses on inert polymers, metals, or ceramics. Integrating living organisms, especially bacteria, presents unique challenges including maintaining cell viability, controlling growth, and ensuring functional expression post-printing. The reported technique involves formulating bioinks that encapsulate bacteria while providing a supportive matrix that preserves their viability during and after printing. The researchers likely optimized parameters such as nozzle pressure, temperature, and bioink composition to balance print fidelity with bacterial survival. The living bacteria can be genetically engineered to express desired proteins or metabolic pathways, enabling the final material to perform specific functions such as biosensing, catalysis, or electrical conductivity.

However, exact details on the types of bacteria used, bioink formulations, and functional demonstrations remain limited in the public summary. It is also unclear how stable and durable these living materials are over time, and what environmental conditions they require for sustained activity.

Near-term Prediction Model

Given the current stage of research, this technology is in the R&D phase with promising pilot demonstrations expected within 12 to 24 months. Initial applications will likely focus on proof-of-concept devices such as biosensors or small-scale bioreactors. Commercial deployment may require 3-5 years to address scalability, regulatory approval, and integration with existing manufacturing workflows. The impact score is moderate to high (around 75/100) due to the transformative potential of living materials, balanced by technical and regulatory hurdles. Confidence is medium (around 65/100) reflecting early-stage innovation with promising but unproven long-term viability.

What to Watch

- Advances in bioink formulations that improve bacterial viability and functional expression.

- Development of standardized protocols for printing diverse bacterial species and genetically engineered strains.

- Demonstrations of functional living materials in real-world applications such as environmental sensors or self-healing coatings.

- Regulatory frameworks addressing biosafety and environmental impact of deploying living materials.

- Integration of living materials with electronic or mechanical components for hybrid smart devices.

- Long-term stability studies and scalability of manufacturing processes.

As this field evolves, interdisciplinary collaboration between synthetic biologists, materials scientists, and engineers will be critical to fully realize the potential of 3D printed living materials.