What Happened

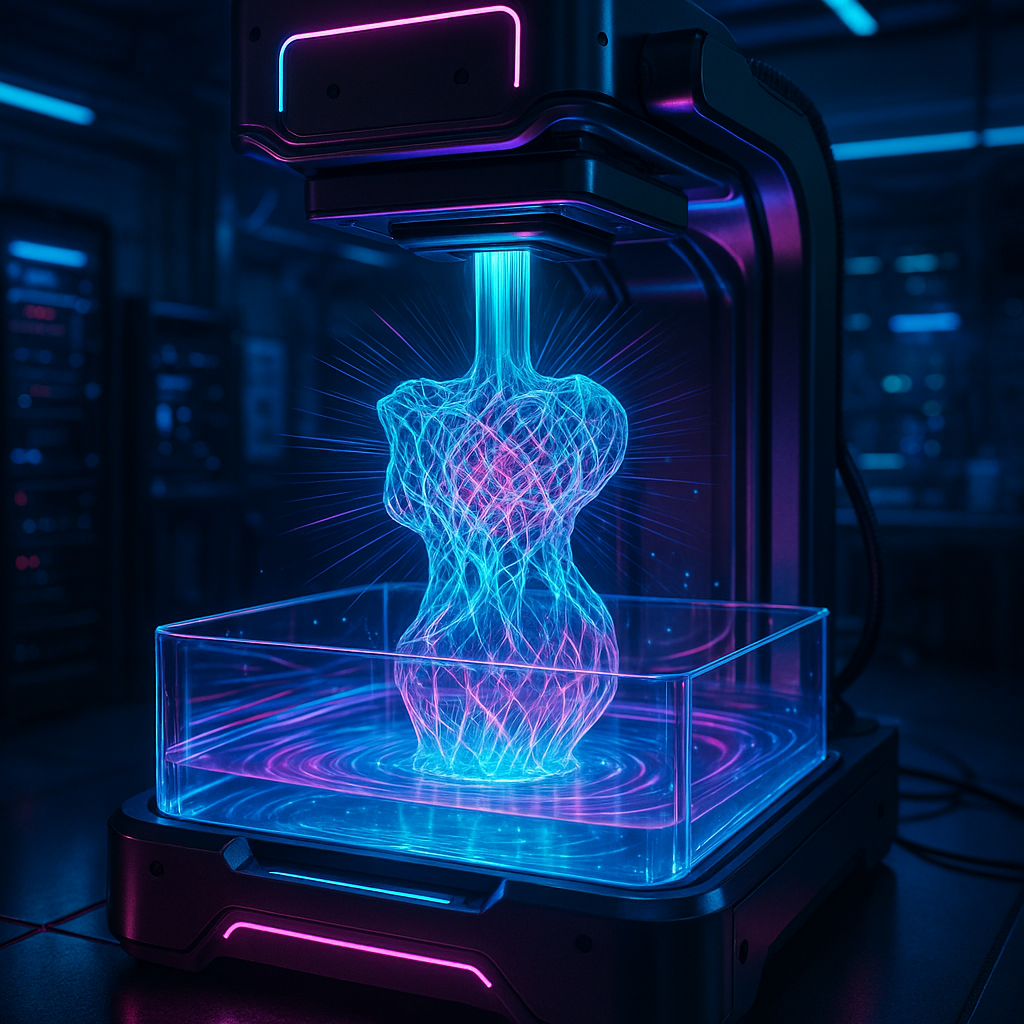

Recently, Notebookcheck reported a breakthrough in volumetric 3D printing technology where a new light-based method can fabricate complex three-dimensional models in an astonishingly short time of 0.6 seconds. This development represents a significant acceleration compared to traditional layer-by-layer 3D printing techniques, which often require minutes to hours to complete similar prints.

Why It Matters

This advancement in volumetric 3D printing is poised to disrupt conventional additive manufacturing by drastically reducing print times, enabling rapid prototyping and mass customization at unprecedented speeds. The ability to produce complex geometries almost instantaneously could benefit industries ranging from medical devices and aerospace to consumer products and research laboratories. Faster printing also implies reduced energy consumption and potentially lower production costs, making 3D printing more accessible and scalable.

Technical Context

Volumetric 3D printing differs fundamentally from traditional layer-based methods. Instead of building objects slice by slice, volumetric printing uses light to polymerize resin simultaneously throughout the volume, creating entire objects in one continuous exposure. The reported technology employs advanced light pattern projection and precise control of photopolymerization kinetics to achieve sub-second solidification of intricate structures.

While the exact technical specifications and mechanisms behind this new light-based process remain undisclosed in the source article, such rapid curing likely involves optimized photoinitiators and sophisticated optics to focus light energy efficiently. This contrasts with stereolithography (SLA) or digital light processing (DLP) printers, which cure resin layer by layer and require mechanical movement of the build platform.

Challenges for volumetric printing include controlling resolution, ensuring uniform curing throughout the volume, and managing material properties to prevent defects. The breakthrough suggests progress in overcoming these hurdles, but detailed performance metrics such as resolution, mechanical strength, and material compatibility are not yet publicly available.

Near-Term Prediction Model

Given the current R&D status and the rapid pace of innovation in volumetric 3D printing, it is reasonable to expect pilot-scale demonstrations and initial commercial applications within 12 to 24 months. Early adopters in specialized fields like biomedical implants or microfluidic devices may benefit first due to the technology’s capability to produce complex internal geometries swiftly.

Industry adoption will depend on further validation of print quality, repeatability, and integration with existing design workflows. Additionally, material development tailored to volumetric curing processes will be critical. The impact score is high, reflecting the transformative potential of drastically accelerated print speeds, but confidence remains moderate until more comprehensive data and real-world use cases emerge.

What to Watch

- Announcements of commercial pilot programs or partnerships leveraging this volumetric printing technology.

- Technical publications detailing the underlying optical and chemical processes enabling sub-second printing.

- Advances in photopolymer resin formulations optimized for rapid volumetric curing.

- Demonstrations showcasing the mechanical properties and resolution limits of printed parts.

- Comparative studies between volumetric printing and established additive manufacturing methods regarding cost, speed, and quality.