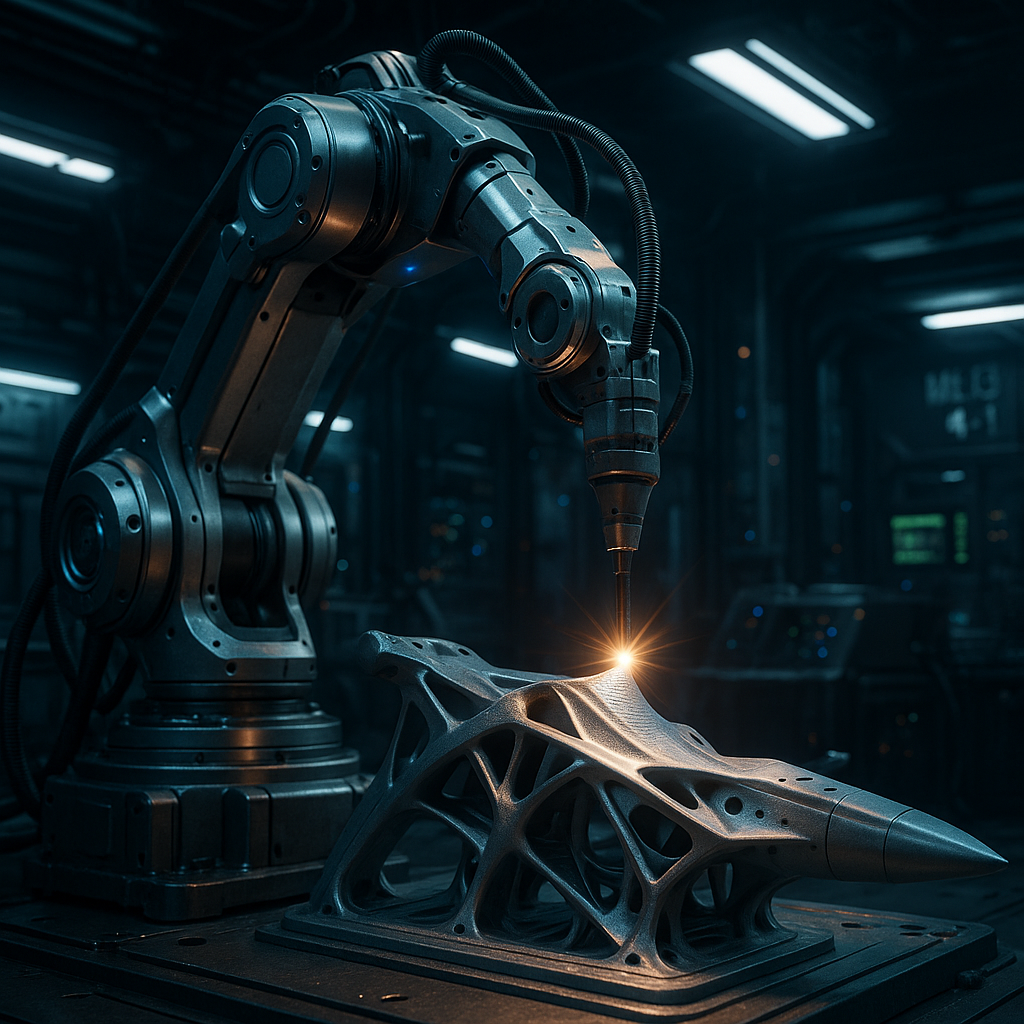

Robins Air Force Base’s Additive Manufacturing Lab is making significant strides in robotic arm 3D printing technology to enhance Air Force readiness, as reported by afmc.af.mil. This development marks a vital step forward in the application of non-planar, multi-axis additive manufacturing within military contexts, leveraging robotic arms to overcome traditional 3D printing constraints.

What Happened

The Robins AFB Additive Manufacturing Lab has integrated robotic arm 3D printing capabilities into its production workflows. While specific technical details remain undisclosed, the lab’s adoption of robotic arms enables complex geometries and part orientations beyond the limitations of planar, layer-by-layer printing. This advancement supports rapid prototyping and on-demand manufacturing of critical aerospace components, directly contributing to enhanced operational readiness for the Air Force.

Why It Matters

Traditional 3D printing methods generally rely on planar, fixed-axis deposition, which limits the complexity and mechanical performance of printed parts. Robotic arm 3D printing introduces multi-axis movement, allowing for continuous, non-planar deposition paths. This can reduce anisotropy in printed parts, improve surface finish, and enable the manufacture of components with integrated features that would otherwise require assembly. For the Air Force, these enhancements translate to faster repair cycles, reduced part inventories, and increased mission flexibility.

Technical Context

Robotic arm 3D printing represents a frontier in additive manufacturing that combines the dexterity of industrial robots with extrusion or directed energy deposition techniques. Unlike gantry or delta 3D printers, robotic arms provide six or more degrees of freedom, enabling printing on curved surfaces and complex orientations. This facilitates true multi-axis additive manufacturing, which can optimize load paths within parts and minimize support structures. The Robins AFB lab’s work likely involves integrating advanced process control, real-time monitoring, and material science to ensure part quality and repeatability in aerospace-grade materials.

Near-Term Prediction Model

Given the current trajectory, robotic arm 3D printing at Robins AFB is in a pilot to early commercial stage. Over the next 12 to 24 months, it is expected that the lab will refine process parameters, expand material compatibility, and validate printed parts under operational conditions. The impact on Air Force maintenance and logistics could be significant, potentially reducing downtime and costs. However, challenges remain in certifying parts for flight-critical applications and scaling production volumes.

What to Watch

- Publication of technical data or case studies demonstrating robotic arm 3D printing performance in aerospace parts at Robins AFB.

- Expansion of material portfolios compatible with multi-axis robotic deposition, including high-strength alloys and composites.

- Development of certification protocols for non-planar printed parts to meet military and aerospace standards.

- Integration of AI-driven process monitoring to enhance print quality and reduce defects.

- Collaborations between Robins AFB and industry partners to commercialize robotic arm 3D printing technologies.

While the full scope of Robins AFB’s robotic arm 3D printing initiatives is still emerging, this advancement underscores the growing importance of non-planar and multi-axis additive manufacturing in high-stakes defense applications. Continued observation of this program will provide valuable insights into the future capabilities and adoption of robotic arm-based 3D printing technologies.