Siemens Energy has recently made a strategic investment in an on-demand additive manufacturing service, as reported by tctmagazine.com on November 14, 2025. This move underscores Siemens Energy’s commitment to leveraging additive manufacturing technologies to transform how spare parts are produced and delivered, particularly in energy sector operations where downtime can be costly.

What Happened

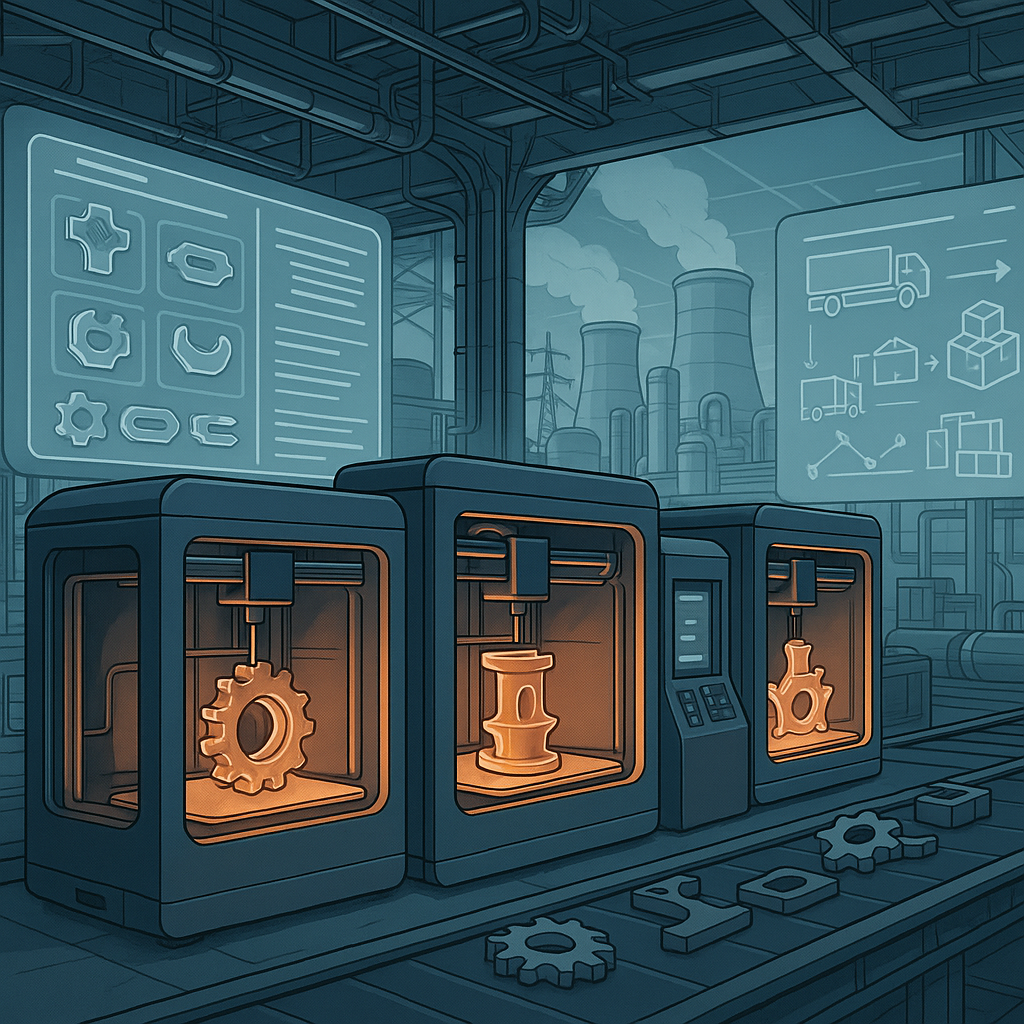

Siemens Energy has invested in a service that enables on-demand additive manufacturing of spare parts. This initiative is designed to enhance the availability and responsiveness of spare parts supply chains by allowing parts to be produced locally and as needed, rather than relying on traditional inventory and logistics models. While the exact details of the service provider and the scale of the investment remain undisclosed, the focus is clearly on integrating additive manufacturing capabilities into Siemens Energy’s operational framework.

Why It Matters

The energy sector, especially power generation and transmission, depends heavily on the rapid availability of critical spare parts to maintain continuous operations. Traditional supply chains can involve long lead times and significant inventory costs, which increase the risk of downtime and financial loss. Siemens Energy’s investment signals a shift towards digital inventory strategies, where parts are stored as digital files and manufactured on-demand near the point of use.

This approach not only reduces physical inventory costs but also enhances supply chain resilience by mitigating risks associated with logistics disruptions, geopolitical uncertainties, or supplier constraints. For a company like Siemens Energy, which operates in a highly regulated and uptime-critical industry, the ability to produce spares quickly and locally can translate into significant operational and economic advantages.

Technical Context

Additive manufacturing (AM), commonly known as 3D printing, enables layer-by-layer fabrication of complex parts directly from digital designs. In industrial settings, AM is increasingly used for prototyping, tooling, and increasingly for end-use parts, especially where customization, complexity, or low volume make traditional manufacturing less economical.

On-demand spare parts production leverages AM technologies such as metal powder bed fusion, directed energy deposition, and polymer extrusion, depending on part requirements. Siemens Energy’s adoption likely involves advanced metal AM processes capable of producing parts that meet stringent mechanical and quality standards required in energy applications.

Integration with digital inventory systems is critical. This includes secure digital part libraries, quality assurance protocols, and supply chain software that can trigger manufacturing based on real-time demand signals. While the article does not detail Siemens Energy’s specific technology stack or software partnerships, these components are essential to a successful on-demand manufacturing ecosystem.

Near-term Prediction Model

Given the current industrial maturity of additive manufacturing and Siemens Energy’s scale, this investment is positioned at the Commercial stage, with pilot projects likely underway or imminent. Within 12 to 24 months, we can expect to see expanded deployment of on-demand AM services across Siemens Energy’s operational sites, particularly for critical or long-lead-time spare parts.

The impact score is projected at 75 out of 100, reflecting significant operational benefits but tempered by challenges such as qualification of AM parts, regulatory compliance, and integration complexity. Confidence is moderate to high at 70 out of 100, given Siemens Energy’s strong industrial expertise and track record in technology adoption.

What to Watch

- Details on the specific additive manufacturing technologies and materials Siemens Energy is deploying for on-demand spare parts.

- Development of digital inventory management systems, including cybersecurity measures to protect digital part files.

- Regulatory and certification progress for AM-produced spare parts in energy sector applications.

- Expansion of the on-demand manufacturing model to other sectors within Siemens or its customer base.

- Collaborations or partnerships with AM technology providers and software firms to enhance the service ecosystem.

While the initial announcement provides limited specifics, Siemens Energy’s investment marks a significant step in the broader adoption of digital inventory and on-demand manufacturing paradigms. This move could serve as a bellwether for other industrial players seeking to modernize their spare parts strategies and improve supply chain agility through additive manufacturing.