What Happened

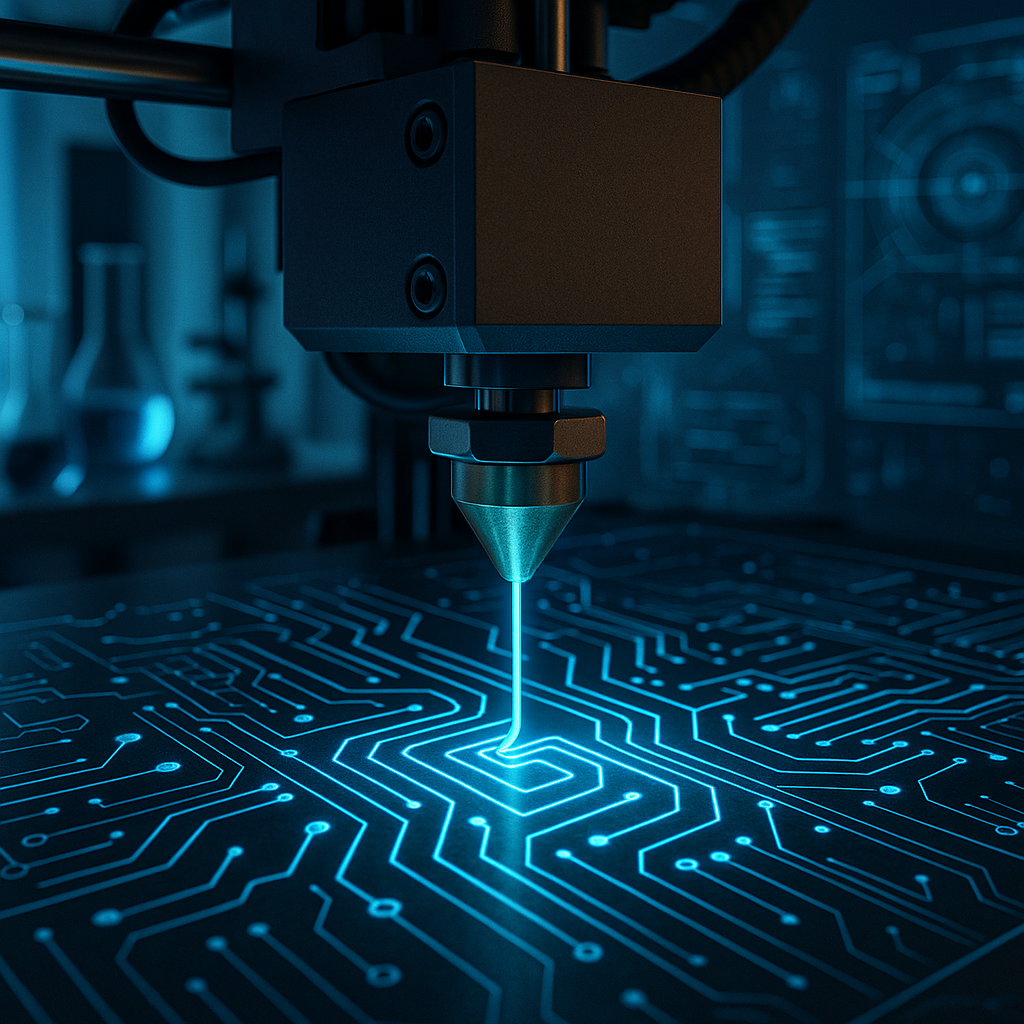

Researchers in Singapore have developed a novel conductive 3D printer filament that promises to transform the way circuits are manufactured. Reported by 3DPrint.com, this advancement could radically change circuit manufacturing forever by enabling direct 3D printing of conductive pathways.

Why It Matters

The innovation addresses a longstanding challenge in additive manufacturing: integrating electronic functionality directly into printed parts. Traditionally, circuits require separate manufacturing steps involving etching, layering, or embedding conductive components post-printing. This new conductive filament enables seamless fabrication of embedded circuits, reducing complexity, cost, and production time. It opens possibilities for rapid prototyping and small-batch production of smart devices, wearables, and bio-integrated electronics.

Moreover, such conductive materials are essential for advancing smart and bio-embedded materials, where electronics must conform to complex shapes or biological interfaces. The Singapore team’s work could catalyze broader adoption of functional 3D printed devices in healthcare, IoT, robotics, and beyond.

Technical Context

While the article does not provide detailed composition data, conductive filaments generally combine polymer matrices with conductive fillers such as carbon nanotubes, graphene, or metal particles. Achieving a balance between printability, mechanical properties, and electrical conductivity is challenging. The Singapore researchers appear to have engineered a filament that maintains sufficient conductivity for circuit applications while being compatible with standard 3D printers.

Key technical considerations include filament extrusion consistency, layer adhesion, resistance levels, and durability under mechanical stress. The new filament likely optimizes filler dispersion and polymer compatibility to overcome common issues like brittleness or conductivity loss after printing.

However, specifics such as resistance metrics, printing temperature ranges, and filament flexibility remain undisclosed, leaving open questions about performance under various operational conditions and integration with multi-material printing setups.

Near-Term Prediction Model

Currently, this conductive filament technology is best classified at the R&D to Pilot stage. Early prototypes demonstrate proof of concept, but broader commercialization and industrial adoption will require further validation, standardization, and scalability.

Within the next 12 to 24 months, we can expect pilot projects and early commercial trials targeting niche markets such as custom electronics prototyping, wearable sensors, and educational kits. Impact potential scores around 75/100, reflecting significant innovation but tempered by technical and manufacturing hurdles. Confidence stands at approximately 65/100 due to limited public data and unknowns about filament longevity and cost-effectiveness.

What to Watch

- Detailed technical specifications and performance benchmarks released by the Singapore research team or affiliated institutions.

- Partnership announcements with 3D printer manufacturers or electronics firms to integrate the filament into commercial workflows.

- Emergence of multi-material printing techniques combining conductive and insulating filaments to fabricate complete electronic devices in a single print.

- Applications in bio-embedded electronics, including flexible sensors or implantable devices requiring biocompatibility alongside conductivity.

- Intellectual property filings or open-source releases that could accelerate adoption and innovation around conductive filaments.

In conclusion, this development marks a promising step toward integrating smart materials directly into 3D printed objects, potentially revolutionizing how circuits and electronics are fabricated. Continued research, transparency, and collaboration will be key to unlocking its full potential.