What Happened

Stratasys, a leading additive manufacturing company, has announced a strategic collaboration with Tritone to integrate metal and ceramic production capabilities into its 3D printing portfolio. This development, reported by 3D Printing Industry, marks a significant expansion from Stratasys’ traditional polymer-based additive manufacturing into the more technically challenging domains of metal and ceramic 3D printing.

Why It Matters

This collaboration is a critical step toward enabling more versatile and high-performance additive manufacturing solutions. Metal and ceramic materials offer superior mechanical, thermal, and chemical properties compared to polymers, making them essential for aerospace, automotive, medical implants, and industrial tooling applications. By incorporating these materials, Stratasys can better serve industries demanding complex, durable parts with precision and customization.

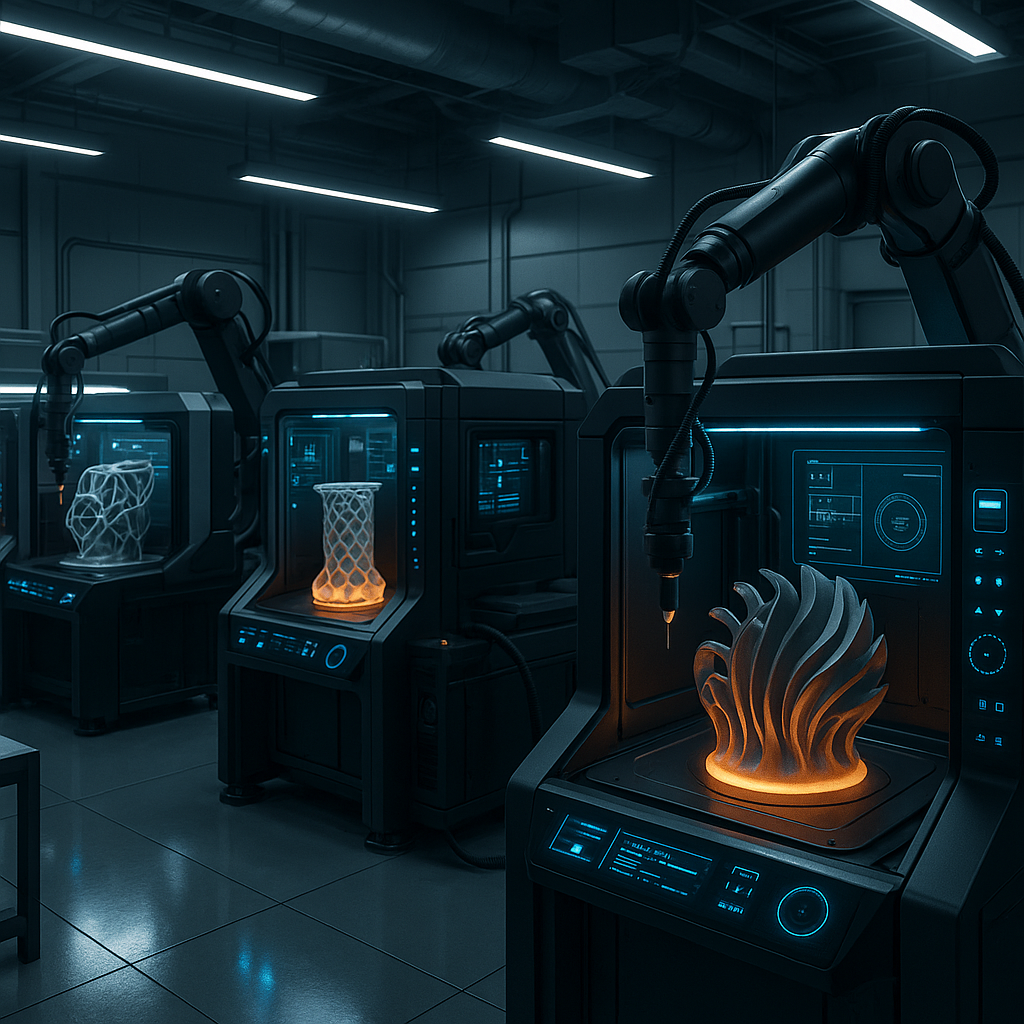

Moreover, this move aligns with the broader trend of collaborative printing—where multiple 3D printing systems or technologies work in concert to produce parts that leverage the strengths of different materials or processes. The integration of metal and ceramic capabilities could facilitate hybrid manufacturing workflows, combining polymer, metal, and ceramic printing in a coordinated manner to create multifunctional components.

Technical Context

Stratasys is traditionally known for its polymer extrusion and photopolymer jetting technologies. Tritone, on the other hand, brings expertise in metal and ceramic additive manufacturing processes, likely involving powder bed fusion or binder jetting methods optimized for these materials. The technical challenge lies in harmonizing these fundamentally different printing approaches—thermoplastic extrusion versus powder-based metal/ceramic printing—into a seamless production ecosystem.

While specific technical details of the collaboration remain undisclosed, potential areas of focus include developing integrated hardware platforms, unified software controls, and post-processing workflows that accommodate multiple material types. Additionally, advances in multi-material printhead design, powder handling, and process parameter optimization will be critical to achieving reliable, high-quality outputs.

The collaborative aspect could also extend to distributed manufacturing models, where multiple printers—each specialized in a material class—operate in a synchronized network to fabricate complex assemblies. This would require robust communication protocols, real-time monitoring, and quality assurance systems to ensure precision and repeatability across different machines and materials.

Near-term Prediction Model

In the next 12 to 24 months, we can expect pilot deployments of combined metal and ceramic printing solutions within Stratasys’ customer base, particularly targeting sectors with high-value, low-volume production needs such as aerospace and medical devices. Initial applications will likely focus on tooling inserts, customized implants, and parts requiring high wear or heat resistance.

Commercial maturity may be limited initially by challenges including process integration complexity, material certification, and cost barriers. However, the collaboration with Tritone positions Stratasys to accelerate R&D efforts and reduce time-to-market for these advanced capabilities. Early adopters will gain competitive advantages by leveraging multi-material collaborative printing workflows to deliver parts with enhanced functionality and reduced lead times.

What to Watch

- Announcements of joint hardware or software platforms enabling integrated polymer, metal, and ceramic printing.

- Case studies or pilot projects demonstrating multi-material part fabrication using collaborative printing methods.

- Advancements in process control and quality assurance tools for hybrid additive manufacturing systems.

- New material formulations or proprietary powders developed by Tritone to optimize compatibility with Stratasys platforms.

- Industry partnerships or customer feedback highlighting the practical benefits and challenges of this collaborative approach.

In summary, the Stratasys-Tritone collaboration is a pioneering move that could redefine collaborative printing by bridging polymer, metal, and ceramic additive manufacturing. While many technical and commercial details remain to be revealed, this initiative signals a future where multi-material, multi-technology 3D printing ecosystems become standard in advanced manufacturing.