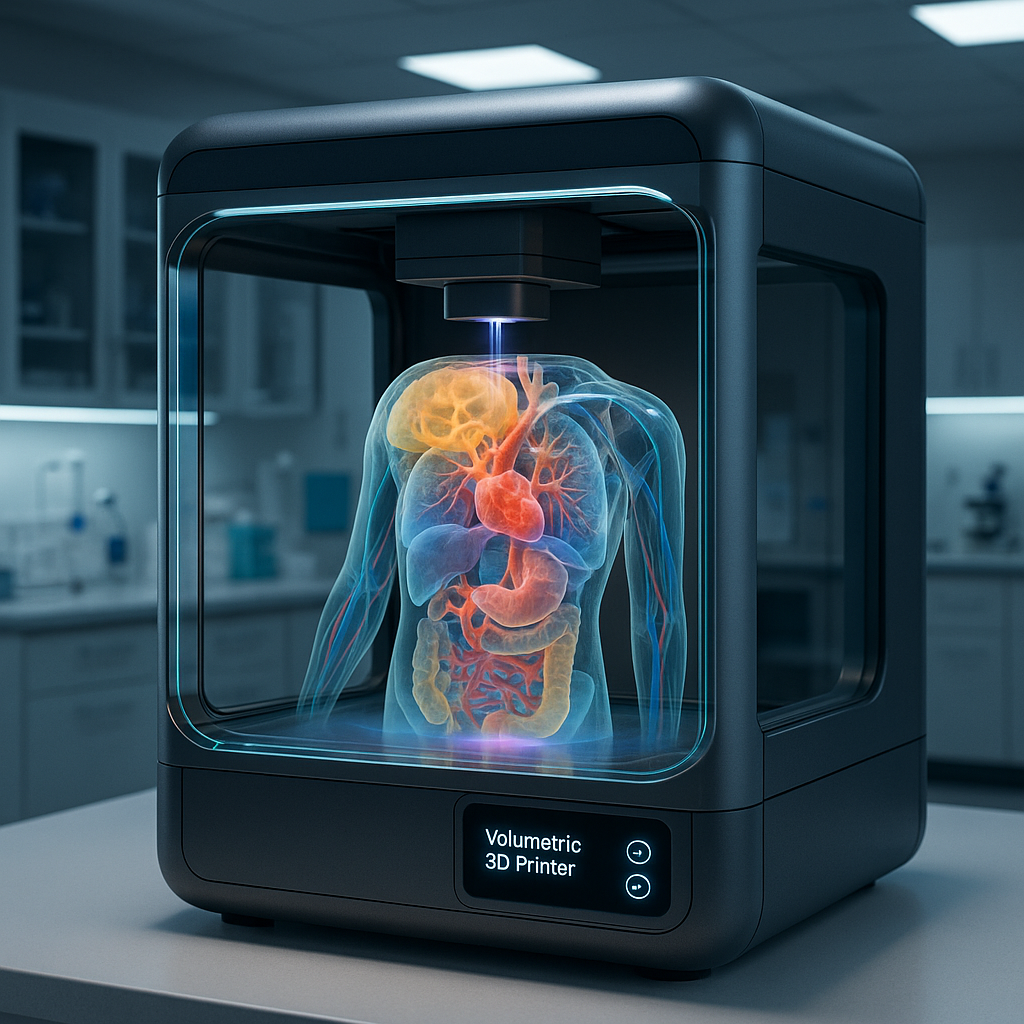

What Happened

Recent developments in volumetric 3D printing, specifically tomographic printing, have enabled the creation of high-resolution, functionally graded, multimaterial biomedical models derived directly from tomographic data sets. This breakthrough was detailed in a study published by Mary Ann Liebert, Inc. in their 3D Printing and Additive Manufacturing journal in May 2018. This work showcases how tomographic printing techniques can translate complex biomedical imaging data directly into tangible, high-fidelity 3D printed models that incorporate multiple materials with graded functional properties.

Why It Matters

The ability to convert tomographic data sets—such as CT or MRI scans—into physical models with precise material variations addresses key challenges in medical diagnostics, presurgical planning, and personalized medicine. Traditional 3D printing workflows often rely on segmented data and single-material prints, which can oversimplify anatomical structures and limit the functional realism of models. By contrast, tomographic printing leverages volumetric data to produce continuous gradients of material properties, enabling models that more accurately mimic tissue heterogeneity and complex anatomical features.

This advancement holds promise for improving diagnostic accuracy by providing clinicians with tactile and visual aids that reflect patient-specific anatomy and pathology in unprecedented detail. Surgeons can rehearse procedures on realistic models tailored to the individual patient, potentially reducing intraoperative risks and improving outcomes. Furthermore, this approach may accelerate biomedical research by facilitating the fabrication of complex tissue phantoms for imaging system calibration and therapeutic device testing.

Technical Context

Tomographic printing is a subset of volumetric additive manufacturing that reconstructs 3D objects from cross-sectional volumetric data using light or other energy sources. Unlike layer-by-layer 3D printing, tomographic printing exposes a rotating volume of photosensitive resin to dynamic light patterns synchronized with rotation, polymerizing the entire object simultaneously. This technique allows for rapid fabrication of complex geometries without the typical layer artifacts.

The study highlighted the integration of functionally graded multimaterial printing within this tomographic framework. This involves modulating the chemical composition and curing parameters spatially within the resin volume to create gradients in mechanical, optical, or biological properties. Achieving this requires precise control over material mixing, exposure timing, and spatial light modulation. The researchers demonstrated this capability by fabricating biomedical models that preserved the spatial distribution of tissue types and structural heterogeneities directly from tomographic imaging data.

While the exact hardware configurations, resin formulations, and software algorithms used were not fully disclosed, the work represents a significant stride toward combining imaging data fidelity with advanced multimaterial volumetric printing.

Near-Term Prediction Model

Currently, tomographic printing with high-resolution multimaterial grading remains largely in the research and pilot phases. Commercial adoption is limited by the complexity of integrating multimaterial resin systems, precise control of curing kinetics, and the need for specialized volumetric printers capable of dynamic light patterning with high spatial and temporal resolution.

Within the next 24 to 36 months, we anticipate incremental improvements in hardware scalability, resin chemistry, and software workflows that will enable broader pilot deployments in biomedical research institutions and specialized clinical centers. Early commercial systems may emerge targeting niche applications such as surgical rehearsal models or imaging phantoms, where the value of enhanced anatomical realism justifies the cost and complexity.

Wider clinical adoption and integration into routine presurgical workflows will require further validation studies, regulatory approvals, and cost reductions.

What to Watch

- Advances in multimaterial resin chemistry enabling faster curing times and broader functional property ranges.

- Improved volumetric printing hardware with higher resolution and dynamic light modulation capabilities.

- Software developments for seamless conversion of biomedical tomographic data sets into printable multimaterial volumetric files.

- Clinical validation studies demonstrating improved surgical outcomes or diagnostic accuracy using tomographic printed models.

- Regulatory pathways and standards development for patient-specific 3D printed biomedical models.

- Collaborations between imaging technology providers, 3D printing hardware manufacturers, and medical institutions to accelerate translation.

In summary, tomographic printing represents a frontier in volumetric 3D printing technology, promising to transform biomedical modeling by directly leveraging volumetric imaging data to produce high-fidelity, functionally graded multimaterial constructs. While still emerging, its potential impact on diagnostics and presurgical planning is substantial and merits close attention as the technology matures.