What Happened

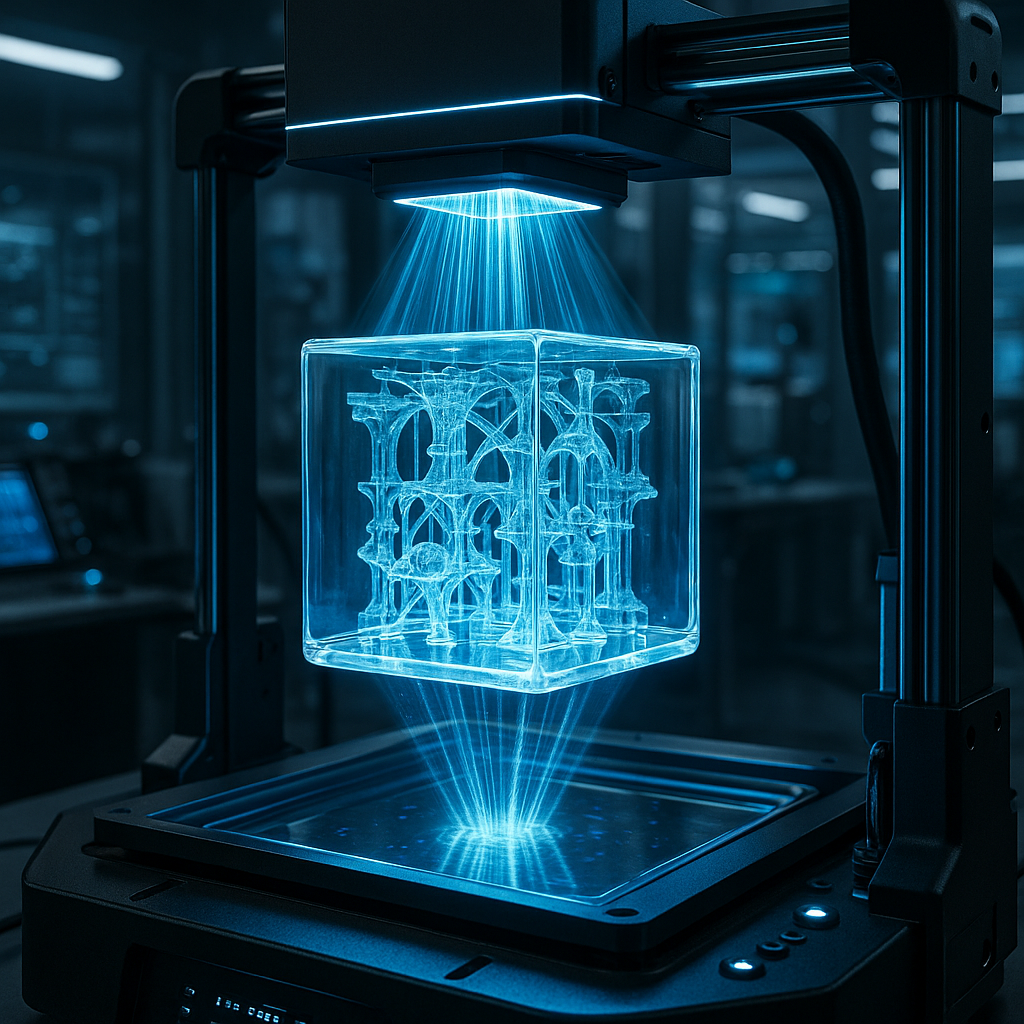

Recent research highlighted by Photonics.com in February 2025 reveals a novel hologram-based approach to tomographic printing, a key technique within volumetric 3D printing. This method leverages holography to project complex light patterns that cure photosensitive resin in three dimensions simultaneously, significantly speeding up the additive manufacturing process while enhancing resolution and structural integrity.

Why It Matters

The integration of holographic techniques into tomographic printing addresses critical limitations of traditional layer-by-layer 3D printing. Conventional methods often suffer from slow build speeds, anisotropic mechanical properties, and resolution constraints. By enabling volumetric curing based on holographic light modulation, this technology promises faster production times and more isotropic material properties, which are crucial for industries requiring rapid prototyping and complex geometries such as biomedical implants, microfluidics, and aerospace components.

Technical Context

Tomographic printing is a subset of volumetric additive manufacturing that reconstructs 3D objects by projecting a series of 2D light patterns from multiple angles into a rotating volume of photosensitive resin. The accumulated light dose solidifies the resin only in the desired 3D shape, eliminating the need for layer-by-layer construction. The new hologram method enhances this by using computer-generated holography to create intricate light fields that precisely control polymerization kinetics within the resin. This allows for higher spatial resolution and complex internal features that were previously difficult to achieve.

While traditional tomographic printing relies on simple projections and mechanical rotation, the holographic approach introduces dynamic light field shaping, which improves the fidelity of the printed object and reduces material waste. However, specific details such as the type of photopolymer used, exact resolution metrics, and scalability remain underreported in the source article.

Near-term Prediction Model

Given the current stage of research, this hologram-based tomographic printing technology is in the late R&D phase, with pilot demonstrations likely within 12 to 24 months. Commercial adoption could follow within 3 to 5 years, contingent on overcoming challenges such as system complexity, cost of holographic projection hardware, and material compatibility. The impact score is estimated at 75 out of 100, reflecting significant potential to disrupt existing additive manufacturing workflows. Confidence in this forecast is moderate (around 65 out of 100) due to limited public data on scalability and industrial validation.

What to Watch

- Advancements in photopolymer chemistry compatible with holographic curing.

- Development of compact, cost-effective holographic projection systems for industrial use.

- Demonstrations of mechanical property improvements and resolution benchmarks compared to conventional 3D printing.

- Integration of this technology into existing additive manufacturing platforms and workflows.

- Intellectual property filings and partnerships between research institutions and manufacturing companies.

In summary, the hologram method represents a promising leap forward in volumetric 3D printing, potentially transforming how complex parts are manufactured by enabling faster, more precise, and structurally sound prints. Continued research and development will clarify its commercial viability and impact on the additive manufacturing landscape.