What Happened

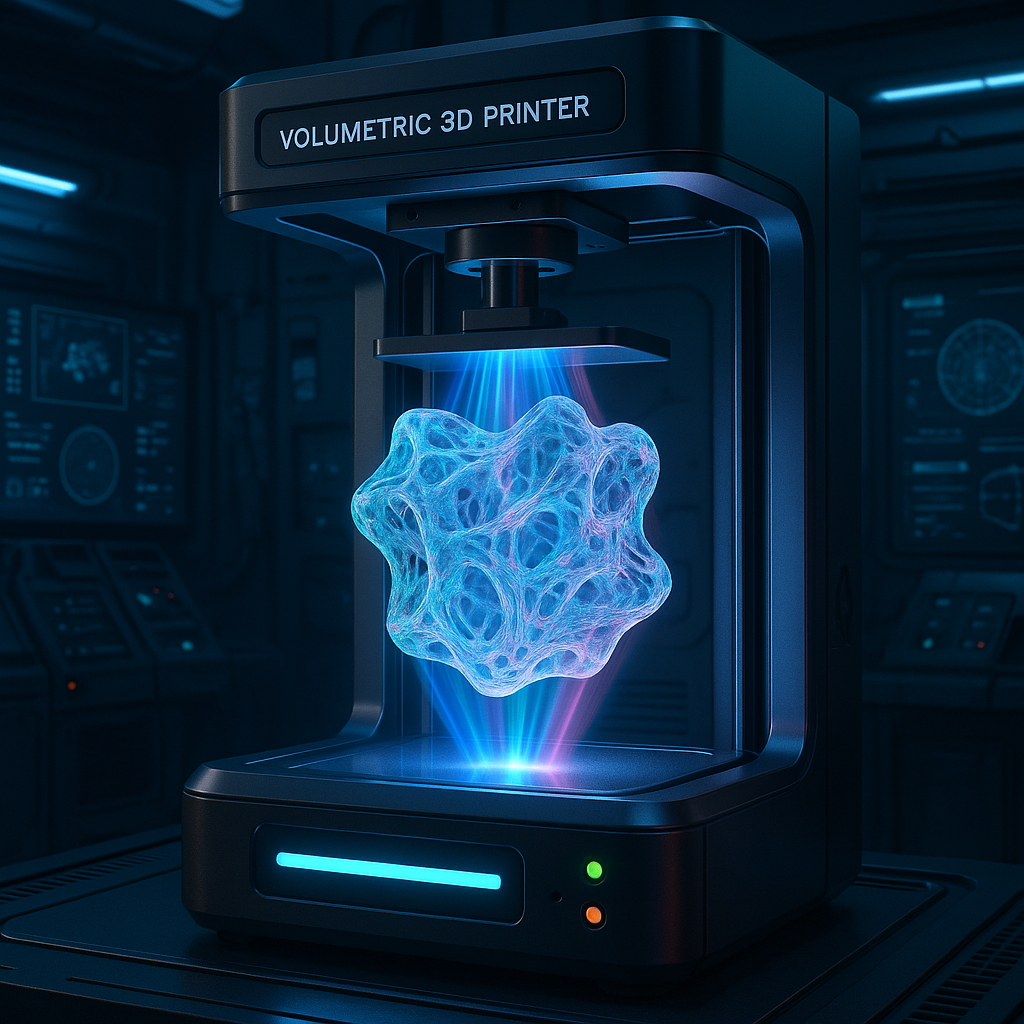

Recent coverage by SouthCoastToday.com highlights the rise of top 3D printing service suppliers driving innovation in global manufacturing. Among the emerging technologies, volumetric 3D printing is gaining attention for its ability to produce complex geometries rapidly and with high precision. While the article does not delve into volumetric printing specifically, its inclusion in the broader context of additive manufacturing innovation signals growing industry interest and potential adoption.

Why It Matters

Volumetric 3D printing represents a paradigm shift from traditional layer-by-layer additive manufacturing methods. Instead of building objects slice by slice, volumetric printing cures or solidifies entire volumes simultaneously, significantly reducing production time. This capability is critical for industries requiring rapid prototyping, intricate internal structures, or biocompatible materials, such as aerospace, medical devices, and automotive sectors.

The technology’s potential to accelerate manufacturing cycles while maintaining or improving precision could disrupt supply chains and enable on-demand production closer to end-users. This shift aligns with the broader trend of decentralizing manufacturing and customizing products at scale, which is essential for meeting evolving market demands.

Technical Context

Volumetric 3D printing typically employs light-based methods such as computed axial lithography (CAL) or tomographic volumetric printing. These techniques project dynamic light patterns into a rotating volume of photosensitive resin, curing the material in three dimensions simultaneously. Unlike conventional stereolithography (SLA) or digital light processing (DLP) printers that cure one layer at a time, volumetric approaches harness complex light modulation and computational algorithms to achieve rapid solidification.

Key technical advantages include:

- Speed: Entire parts can be printed in seconds to minutes rather than hours.

- Complexity: Ability to create intricate internal channels and overhangs without support structures.

- Material Efficiency: Reduced waste due to minimal support requirements.

However, challenges remain in scaling volumetric printing to larger build volumes, expanding compatible materials beyond photopolymers, and ensuring mechanical properties meet industrial standards. Current implementations are mostly in research or pilot phases, with limited commercial availability.

Near-term Prediction Model

Based on current trends and industry signals, volumetric 3D printing is expected to progress from pilot to early commercial stages within the next 12 to 24 months. Early adopters will likely be specialized service providers and high-value industries such as medical devices and aerospace components where speed and complexity justify investment.

Incremental improvements in resin chemistry, printer hardware, and software control will drive broader adoption. Partnerships between volumetric technology developers and established 3D printing service suppliers, as hinted by the broader manufacturing innovation coverage, will be critical to accelerate commercialization.

What to Watch

- Material Development: Advances in biocompatible and engineering-grade resins compatible with volumetric printing.

- Scale and Resolution: Improvements enabling larger build volumes without sacrificing detail or mechanical integrity.

- Industry Partnerships: Collaborations between volumetric printing startups and established manufacturing service providers.

- Regulatory Approvals: Particularly for medical and aerospace applications where certification is crucial.

- Cost Reduction: Economies of scale and hardware innovations that make volumetric printers more accessible.

While volumetric 3D printing remains under-covered in mainstream additive manufacturing news, its disruptive potential warrants close attention from innovators and industry stakeholders aiming to harness the next leap in rapid manufacturing technology.