In a recent Detroit Free Press article, one of the top 3D printing service suppliers highlighted the transformative role of volumetric 3D printing in global manufacturing. This emerging technology represents a paradigm shift from traditional layer-by-layer additive methods to rapid, volumetric fabrication that promises unprecedented speed and complexity in part production.

What Happened

Volumetric 3D printing has gained renewed attention as a frontier additive manufacturing technique capable of fabricating entire objects simultaneously within a volume, rather than through sequential layering. The Detroit Free Press article underscores how leading service providers are investing in volumetric printing to drive innovation and meet growing demands for complex, lightweight, and high-strength components across aerospace, medical, and automotive sectors.

Although specific commercial deployments remain limited, pilot projects and R&D efforts are accelerating, signaling a shift from experimental setups to scalable manufacturing solutions. The article highlights the supplier’s strategic emphasis on volumetric printing as a key differentiator in the competitive 3D printing market.

Why It Matters

Volumetric 3D printing addresses critical limitations of conventional additive manufacturing, such as slow build times, anisotropic mechanical properties, and geometric constraints. By curing or solidifying an entire 3D object simultaneously inside a photosensitive resin or other medium, volumetric approaches can reduce print times from hours to minutes.

This speed advantage enables rapid prototyping and mass customization at scales previously unattainable, offering manufacturers the agility to innovate faster and reduce time-to-market. Additionally, volumetric printing can produce parts with smooth surfaces and complex internal geometries without support structures, enhancing functional performance and reducing post-processing.

The technology’s potential to disrupt supply chains and enable localized production aligns with broader industrial trends toward digital manufacturing and sustainability. As major suppliers integrate volumetric printing into their service portfolios, the industry could witness a significant leap in manufacturing capabilities.

Technical Context

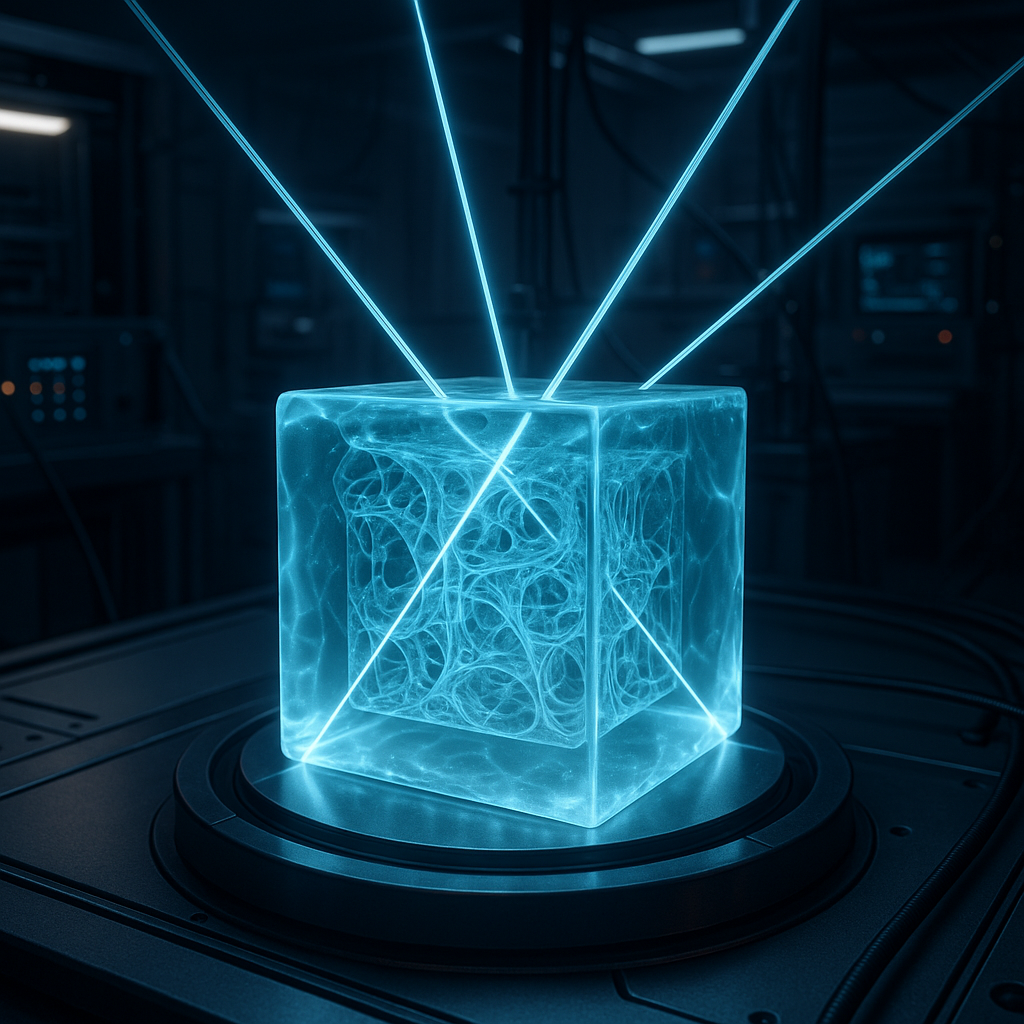

Volumetric 3D printing encompasses several approaches, including computed axial lithography (CAL), tomographic volumetric additive manufacturing, and holographic polymerization. These methods rely on projecting light patterns or volumetric energy doses into a photosensitive resin or polymerizable medium from multiple angles, inducing polymerization simultaneously throughout the volume.

Unlike traditional stereolithography (SLA) or digital light processing (DLP) that build objects layer by layer, volumetric techniques exploit the physics of light scattering and photopolymerization kinetics to cure entire 3D shapes in a single step. This requires precise control over light exposure, resin chemistry, and optical system calibration to achieve accurate resolutions and mechanical properties.

Current challenges include material limitations—primarily photopolymers with constrained mechanical strength—and scaling volumetric printing to larger build volumes while maintaining part fidelity. Research is ongoing to expand compatible materials, improve resolution, and integrate multi-material capabilities.

Near-Term Prediction Model

Volumetric 3D printing is presently in the Pilot stage of maturity, with expected broader commercial adoption within the next 24 to 36 months. The impact score is estimated at 75 out of 100, reflecting substantial potential to transform manufacturing workflows, though tempered by technical and material challenges. Confidence in this forecast stands at 70, acknowledging uncertainties around scalability and market adoption rates.

Key risks include material performance limitations, high equipment costs, and integration complexities with existing manufacturing ecosystems. Moreover, regulatory and certification pathways for volumetrically printed parts, especially in safety-critical industries, remain underdeveloped.

What to Watch

- Advancements in photopolymer resin chemistry to improve mechanical strength, durability, and multi-material compatibility.

- Development of larger-scale volumetric printing systems capable of producing industrial-sized components with high precision.

- Strategic partnerships between volumetric printing technology developers and established manufacturing service suppliers to accelerate commercialization.

- Regulatory frameworks and standards emerging for volumetric printed parts, particularly in aerospace and medical device sectors.

- Demonstrations of volumetric printing applications that showcase unique design freedoms and performance benefits unattainable with traditional 3D printing.

While volumetric 3D printing remains an emerging technology, its potential to revolutionize additive manufacturing is gaining tangible momentum. Continued R&D and pilot deployments by leading service providers, as reported by Detroit Free Press, position volumetric printing as a technology to watch closely in the coming years.