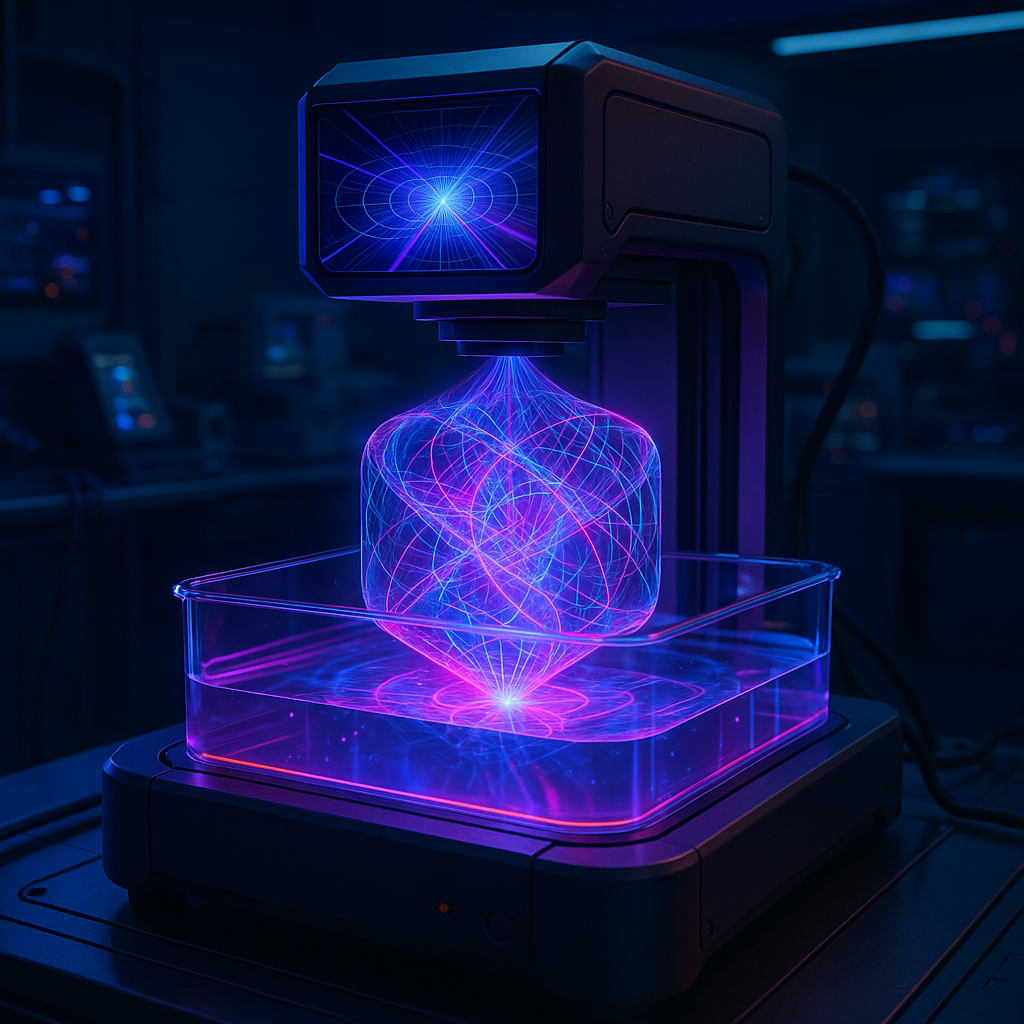

Recent developments at the MakerLab at Binghamton University highlight the growing interest in volumetric 3D printing, a cutting-edge additive manufacturing technique that promises to revolutionize how complex objects are fabricated. Unlike traditional layer-by-layer 3D printing methods, volumetric printing constructs entire three-dimensional objects simultaneously by projecting light patterns into a photosensitive resin, enabling rapid production speeds and intricate geometries.

What Happened

Binghamton University’s MakerLab has recently incorporated volumetric 3D printing into its suite of fabrication tools, signaling an institutional commitment to exploring this nascent technology. While the detailed operational capabilities and specific applications of their volumetric printers remain undisclosed, their inclusion within an academic MakerLab setting suggests an emphasis on experimentation, prototyping, and educational outreach. This development is part of a broader trend where academic and public maker spaces serve as incubators for emerging 3D printing technologies beyond the more commonly accessible filament or resin-based printers.

Why It Matters

Volumetric 3D printing represents a significant leap forward in additive manufacturing. Traditional 3D printing methods, such as fused deposition modeling (FDM) or stereolithography (SLA), build objects layer by layer, which can be time-consuming and prone to defects like layer delamination. In contrast, volumetric printing cures an entire volume of resin at once, drastically reducing print times from hours to minutes or even seconds depending on the object size and complexity.

This speed advantage, combined with the ability to create highly complex internal structures without the need for support materials, opens new possibilities for industries ranging from biomedical implants to aerospace components. For MakerLabs, the technology offers a powerful tool for rapid prototyping and iterative design, enabling students and researchers to push the boundaries of design complexity and functional integration.

Technical Context

Volumetric 3D printing is typically implemented through techniques such as computed axial lithography (CAL), which uses a series of 2D light projections from multiple angles to polymerize a photosensitive resin volumetrically. This approach differs fundamentally from traditional vat photopolymerization by eliminating the need for layer-by-layer curing and associated mechanical movements.

Key technical challenges remain, including optimizing resin formulations to balance curing speed and mechanical properties, improving resolution and surface finish, and scaling the process for larger build volumes. Additionally, controlling heat dissipation and managing oxygen inhibition effects during rapid polymerization are active areas of research. The specific hardware and software configurations used at Binghamton University’s MakerLab have not been publicly detailed, leaving some uncertainty about their approach and capabilities.

Near-term Prediction Model

In the next 12 to 24 months, volumetric 3D printing is expected to transition from primarily research-focused prototypes to pilot commercial applications, especially in sectors demanding rapid production of complex parts. Academic and public MakerLabs will likely continue to serve as critical testing grounds for refining the technology and expanding its user base.

Commercial adoption will hinge on overcoming current limitations in material diversity and print size while demonstrating clear advantages over established methods. As the technology matures, we anticipate incremental improvements in printer cost, reliability, and ease of use, making volumetric printing more accessible beyond specialized labs.

What to Watch

- Advances in resin chemistry tailored for volumetric curing that improve mechanical strength and biocompatibility.

- Development of larger-scale volumetric printers capable of producing industrial-sized components.

- Integration of volumetric printing with multi-material and multi-functional printing techniques.

- Emerging applications in biomedical devices, such as patient-specific implants and tissue scaffolds.

- Collaborations between academic institutions and industry to accelerate commercialization pathways.

While volumetric 3D printing is still in its early stages, the momentum generated by institutions like Binghamton University’s MakerLab underscores its potential as a transformative manufacturing technology. Continued research and development will be critical to unlock its full capabilities and broaden its impact across diverse fields.