What Happened

In a recent development highlighted by 3D Printing Industry, Intrepid Automation has partnered with Rapid Fluidics to enhance microfluidic production in the United States by integrating advanced 3D printing techniques. This collaboration is leveraging volumetric 3D printing—a cutting-edge additive manufacturing technology that creates complex three-dimensional structures in a single step—to address long-standing challenges in microfluidic device fabrication.

Why It Matters

Microfluidic devices, which manipulate very small volumes of fluids through channels on the scale of micrometers, are critical components in a variety of fields including medical diagnostics, drug development, and chemical analysis. Traditional manufacturing methods for these devices have often been slow, costly, and limited in geometric complexity. The integration of volumetric 3D printing by Intrepid Automation and Rapid Fluidics marks a significant leap forward because it enables rapid, scalable, and precise production of highly intricate microfluidic architectures.

This advancement could dramatically accelerate the availability of microfluidic devices domestically, reducing reliance on overseas manufacturing and supply chain vulnerabilities. It also opens new possibilities for customization and innovation in device design, potentially leading to breakthroughs in point-of-care diagnostics and personalized medicine.

Technical Context

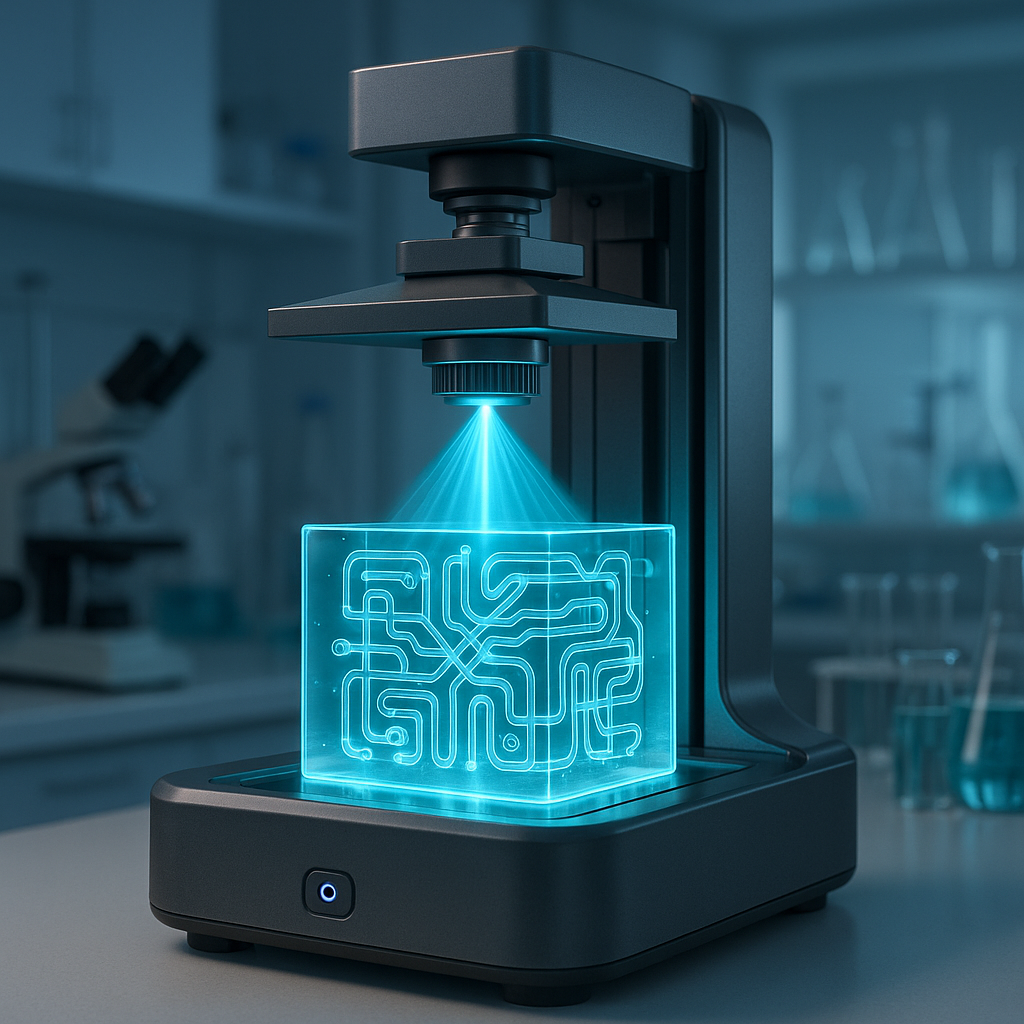

Volumetric 3D printing differs fundamentally from traditional layer-by-layer additive manufacturing methods. Instead of building objects slice by slice, volumetric printing uses light patterns projected into a photosensitive resin to solidify an entire 3D structure simultaneously. This approach drastically reduces print times and eliminates common issues such as layer lines or anisotropic mechanical properties.

In the context of microfluidics, volumetric printing allows for the creation of complex internal channel networks with smooth surfaces and precise dimensional control, which are essential for reliable fluid flow and device performance. The partnership between Intrepid Automation and Rapid Fluidics likely leverages proprietary hardware and resin formulations optimized for micro-scale resolution and biocompatibility, although specific technical details remain undisclosed.

Near-term Prediction Model

Given the current pilot-stage status of volumetric 3D printing in microfluidic manufacturing, the technology is expected to transition into commercial-scale production within the next 12 to 24 months. Early adopters in medical device companies and research institutions will likely drive initial demand, focusing on rapid prototyping and small-batch production of specialized devices.

The impact score for this technology integration is estimated at 75 out of 100, reflecting its substantial potential to disrupt traditional manufacturing paradigms while acknowledging remaining challenges such as material properties, regulatory approvals, and scalability. Confidence in this trajectory is moderate to high (around 70 out of 100), based on current technological maturity and industry interest.

What to Watch

- Material Innovations: Development of new photopolymer resins tailored for microfluidic applications, balancing resolution, biocompatibility, and chemical resistance.

- Regulatory Milestones: Approvals and certifications for 3D printed microfluidic devices in clinical and commercial settings.

- Scale-up Strategies: Advances in volumetric printer throughput and automation that enable large-volume manufacturing.

- Competitive Partnerships: Other collaborations or startups entering volumetric printing for microfluidics, potentially accelerating innovation.

- Integration with Other Technologies: Combining volumetric printing with microelectronics or sensors to create multifunctional lab-on-chip devices.

While the partnership between Intrepid Automation and Rapid Fluidics is a promising indicator of volumetric 3D printing’s transformative potential in microfluidics, continued observation is required to assess how this technology matures and integrates into broader manufacturing ecosystems.