What Happened

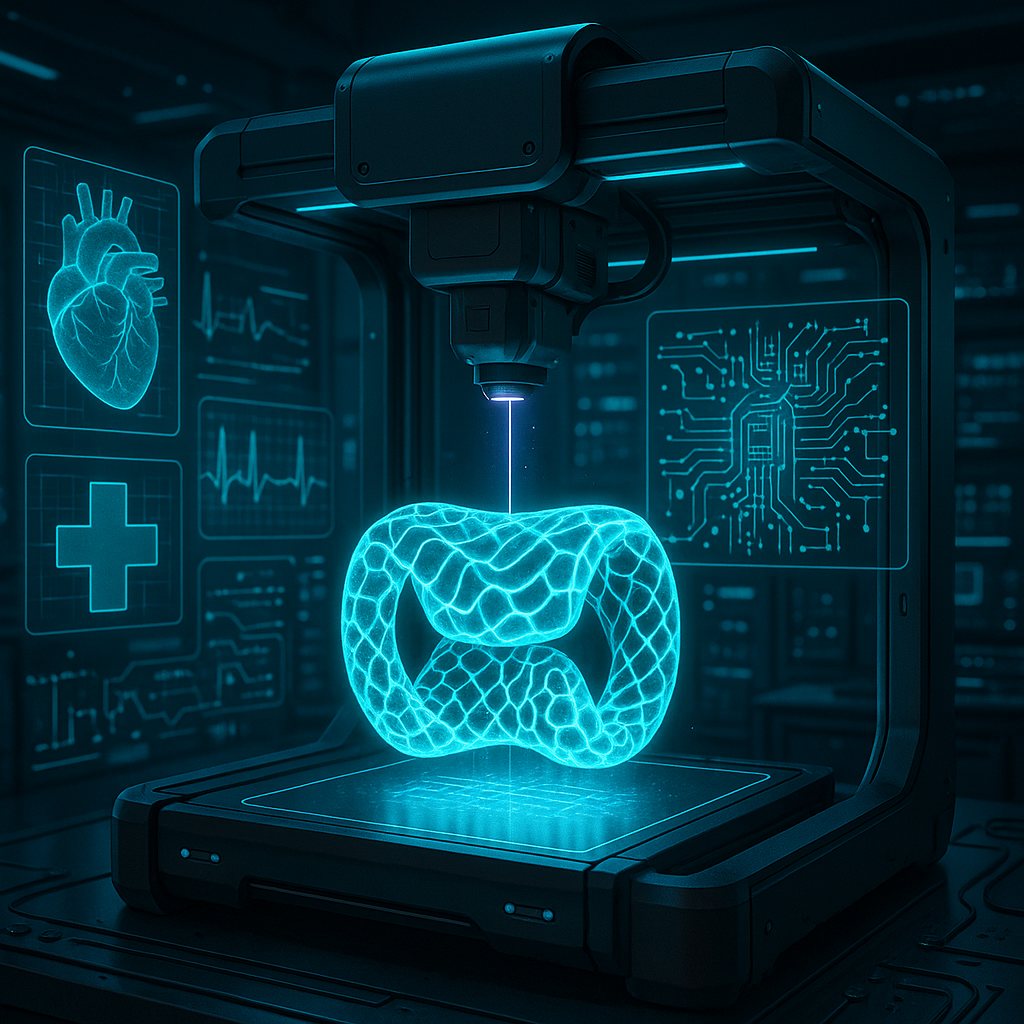

Researchers at the University of Texas at Austin have announced a breakthrough in volumetric 3D printing technology that promises to transform the manufacturing of next-generation medical devices and stretchable electronics. This advancement leverages volumetric printing’s unique ability to fabricate complex, three-dimensional objects rapidly and with intricate internal geometries that traditional layer-by-layer 3D printing struggles to achieve.

Why It Matters

The implications of this breakthrough are significant for industries reliant on miniaturized, flexible, and biocompatible components. Medical devices, especially implantables and wearables, require precise, customizable geometries and materials that can conform to biological tissues. Similarly, stretchable electronics demand flexible substrates and conductive pathways that maintain performance under deformation. Volumetric 3D printing’s ability to produce these complex architectures in a single, continuous process could drastically reduce production times and costs, while enabling designs previously impossible to manufacture.

Technical Context

Volumetric 3D printing differs fundamentally from conventional additive manufacturing methods. Instead of building objects layer-by-layer, it uses computed tomography principles to project light patterns into a photosensitive resin from multiple angles simultaneously, polymerizing the entire volume at once. This results in fabrication speeds orders of magnitude faster than traditional methods and allows for seamless internal structures without layer interfaces.

The UT Austin team has optimized this approach to produce stretchable and biocompatible materials suitable for medical and electronic applications. While the precise chemistry and hardware improvements remain under wraps, the breakthrough likely involves advancements in resin formulation and light patterning algorithms to enhance resolution, mechanical properties, and functional integration.

However, some technical details remain unknown, such as scalability limits, long-term material stability, and integration with existing manufacturing workflows. These factors will be critical in determining how soon and widely the technology can be adopted.

Near-term Prediction Model

Currently, volumetric 3D printing technology is transitioning from the research and development phase toward pilot demonstrations in specialized applications. Given the complexity of medical device certification and the need for rigorous material testing, broad commercial deployment is likely 24 to 36 months away. Early adopters will probably be high-value, low-volume markets such as custom implants and prototype stretchable sensors.

We assign an impact score of 75 out of 100, reflecting the technology’s disruptive potential balanced against existing maturity and integration challenges. Confidence in this timeline is moderate at 65 out of 100, as unforeseen technical hurdles or regulatory delays could shift progress.

What to Watch

- Publication of detailed technical data and open demonstrations of volumetric printing with biocompatible, stretchable materials.

- Partnerships between UT Austin researchers and medical device or electronics manufacturers to pilot production-scale applications.

- Regulatory approvals and standards development for volumetrically printed medical implants and wearable electronics.

- Advances in resin chemistry enabling multi-material printing and enhanced functional integration.

- Emergence of commercial volumetric 3D printers tailored for medical and flexible electronics markets.

Overall, this volumetric 3D printing breakthrough from UT Austin marks a pivotal step toward realizing rapid, complex fabrication of next-generation medical and electronic devices. Continued monitoring of technological refinements, industry collaborations, and regulatory milestones will be essential to gauge its trajectory and ultimate impact.