Recent developments in volumetric 3D printing have begun to attract attention beyond traditional additive manufacturing circles, as highlighted in a recent article from binghamton.edu discussing 3D printing in MakerLabs. Volumetric 3D printing, a technology that fabricates objects in a single step by curing entire volumes of resin simultaneously rather than layer-by-layer, is poised to disrupt conventional additive manufacturing paradigms.

What Happened

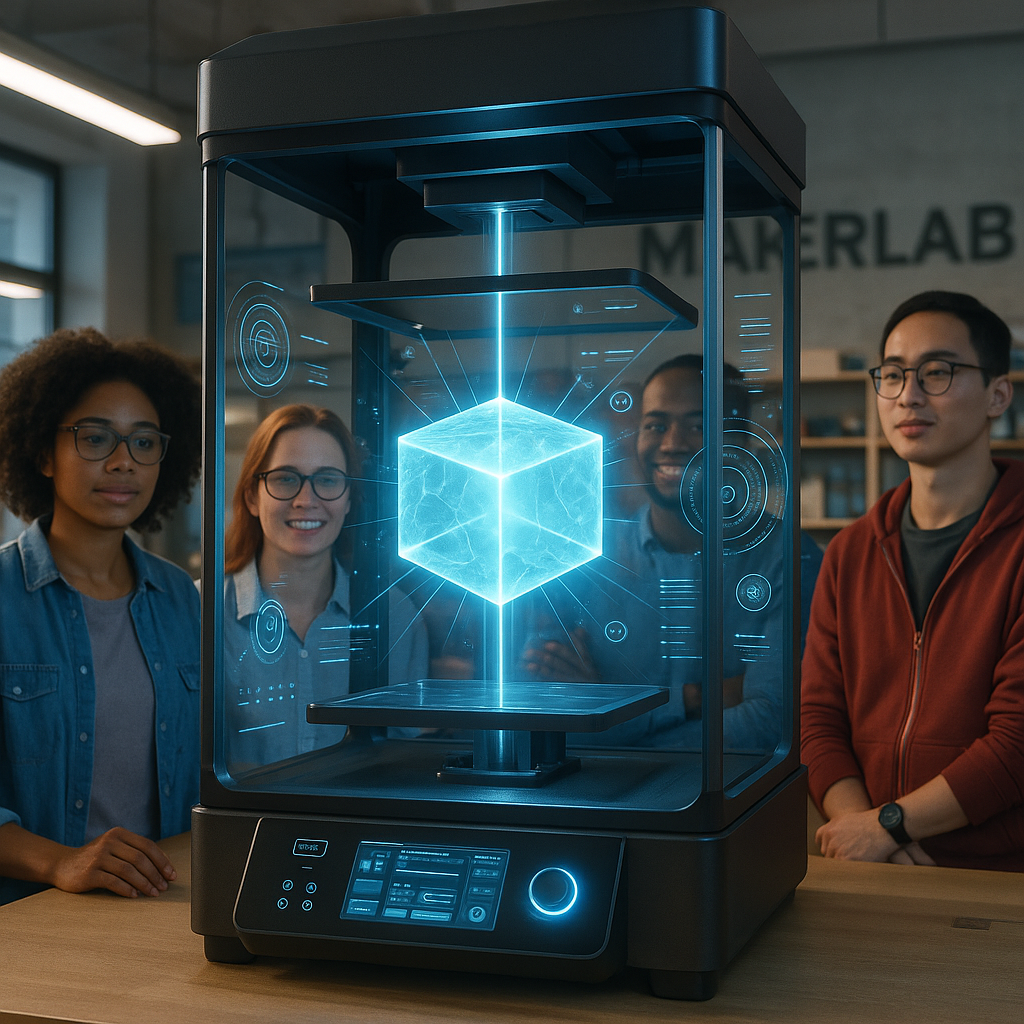

The MakerLab environments, such as those featured at binghamton.edu, are increasingly incorporating advanced 3D printing techniques, including volumetric 3D printing. While the article does not delve deeply into volumetric printing specifics, its mention within the context of evolving MakerLab capabilities signals growing institutional interest. This reflects a broader trend where volumetric 3D printing systems are transitioning from research prototypes to accessible tools within community labs and educational settings.

Why It Matters

Volumetric 3D printing offers transformative advantages over traditional layer-by-layer methods. By curing an entire 3D object simultaneously using intersecting light beams or computed tomography principles, it drastically reduces print times from hours to mere seconds or minutes. This speed gain opens new possibilities for rapid prototyping, complex geometries, and delicate structures that are difficult or impossible to produce with conventional printers. Moreover, the layerless approach eliminates anisotropy and surface artifacts inherent in layered printing, improving mechanical properties and surface finish.

Technical Context

Traditional 3D printing methods such as stereolithography (SLA) and fused deposition modeling (FDM) rely on sequential layer deposition, which limits speed and introduces layer lines. Volumetric 3D printing employs volumetric photopolymerization, where a photosensitive resin is exposed to patterned light fields from multiple angles simultaneously. Techniques like computed axial lithography (CAL) project dynamic light patterns while rotating the resin volume, curing the object in a single continuous exposure. This requires precise control of light modulation, resin chemistry, and computational algorithms to ensure accurate 3D dose distribution.

Currently, volumetric printers are mostly in the pilot stage, with limited commercial models available primarily for small-scale or specialized applications. Challenges include optimizing resin formulations for fast curing without compromising material properties and scaling up build volumes while maintaining resolution and uniformity.

Near-term Prediction Model

Within the next 12 to 24 months, volumetric 3D printing is expected to progress from pilot deployments in MakerLabs and research institutions to early commercial adoption in niche markets such as biomedical devices, microfluidics, and rapid prototyping of complex parts. The technology’s maturity stage remains at Pilot, with ongoing R&D to improve materials and hardware. Impact scores are moderate to high (around 65/100) due to its potential to revolutionize speed and quality, but confidence remains cautious (around 60/100) because of technical and scale-up challenges.

What to Watch

- Advances in photopolymer resin chemistry tailored for volumetric curing to enhance mechanical and functional properties.

- Development of larger build volumes and higher resolution volumetric printers suitable for industrial applications.

- Integration of volumetric printing systems into MakerLabs and educational environments to democratize access and spur innovation.

- Emergence of hybrid manufacturing approaches combining volumetric printing with traditional additive or subtractive methods.

- Intellectual property developments and standardization efforts around volumetric printing processes and materials.

While volumetric 3D printing remains an emerging technology, its inclusion in MakerLab discussions signals growing momentum. Continued interdisciplinary research and collaboration between academia, industry, and community labs will be critical to overcoming current limitations and unlocking the full potential of this rapid, layerless additive manufacturing frontier.