Volumetric 3D printing is gaining attention as a transformative additive manufacturing technique, with recent developments showcased in academic settings such as the 3D Printing In the MakerLab | Libraries – Binghamton University. This article synthesizes the current state, importance, and future trajectory of volumetric 3D printing, a method distinct from traditional layer-by-layer processes.

What Happened

Binghamton University’s MakerLab has incorporated volumetric 3D printing into its suite of additive manufacturing technologies, signaling growing institutional interest. While the detailed technical implementations at the MakerLab remain undisclosed, their inclusion of volumetric 3D printing highlights recognition of its potential in educational and research contexts. This marks a step towards broader adoption beyond industrial research labs, suggesting that volumetric 3D printing is becoming accessible to academic and maker communities.

Why It Matters

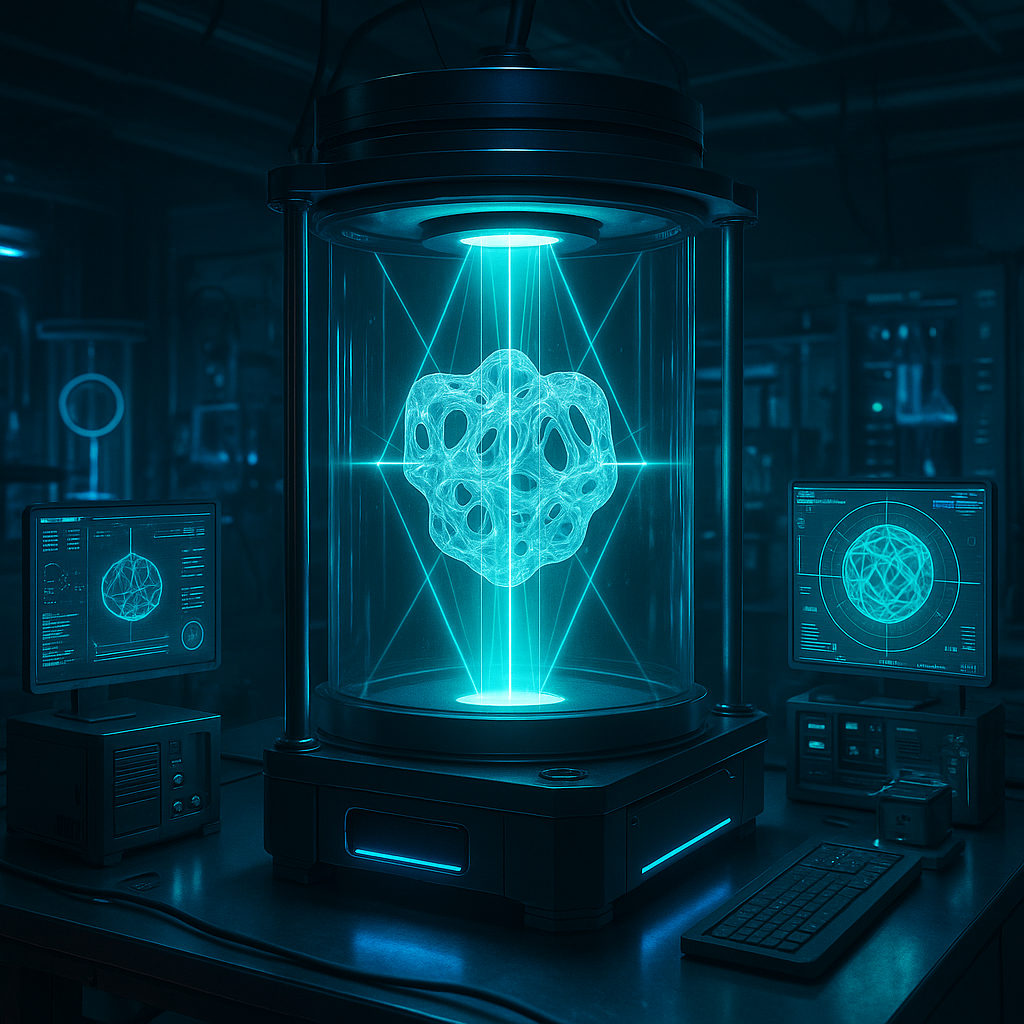

Volumetric 3D printing represents a paradigm shift in how three-dimensional objects are fabricated. Unlike conventional 3D printing methods that build objects layer by layer, volumetric printing cures an entire volume of material simultaneously using intersecting light fields or other volumetric energy sources. This approach drastically reduces print times and allows for the creation of complex internal structures without the need for support materials.

For educational institutions like Binghamton University, integrating volumetric 3D printing offers students and researchers exposure to cutting-edge manufacturing methods. It encourages innovation in design and material science and may accelerate prototyping cycles. More broadly, volumetric 3D printing has the potential to revolutionize industries ranging from biomedical devices to aerospace by enabling rapid, high-resolution fabrication of intricate parts.

Technical Context

Volumetric 3D printing typically relies on the simultaneous projection of light patterns into a photosensitive resin or other curable medium. Techniques such as computed axial lithography (CAL) use rotating light projections to selectively solidify resin in a volumetric fashion. This contrasts with stereolithography (SLA) or fused deposition modeling (FDM), which sequentially build layers.

The technology demands precise control of light intensity, timing, and spatial distribution to ensure accurate curing throughout the volume. Challenges include managing resin properties, avoiding overexposure or undercuring, and achieving consistent resolution. Current volumetric printers are often limited in build size and material variety but excel in speed and geometric complexity.

Details about the specific volumetric 3D printing systems used at Binghamton University’s MakerLab are not publicly available. It is unknown which proprietary or open-source hardware and software solutions they employ or the materials they have experimented with.

Near-term Prediction Model

Volumetric 3D printing is currently in the Pilot stage of maturity. Over the next 12 to 24 months, the technology is expected to transition toward more robust commercial applications, especially as material science advances and system costs decrease.

The impact score is estimated at 75 out of 100, reflecting strong potential to disrupt existing additive manufacturing workflows by enabling faster production and novel geometries. Confidence in this trajectory is moderate at 65 due to technical challenges and limited widespread adoption.

What to Watch

- Material innovation enabling a broader range of resins and composites compatible with volumetric curing.

- Development of scalable volumetric printing systems capable of larger build volumes without sacrificing resolution.

- Integration of volumetric printing with hybrid manufacturing workflows combining subtractive and additive methods.

- Emerging software tools for precise control and simulation of volumetric curing processes.

- Research outputs and case studies from academic institutions like Binghamton University demonstrating educational and practical applications.

In conclusion, volumetric 3D printing is poised to redefine additive manufacturing by offering unprecedented speed and design freedom. The inclusion of this technology in academic MakerLabs is a promising sign of its growing accessibility and future impact. However, continued research, material development, and system refinement remain critical to unlocking its full potential.